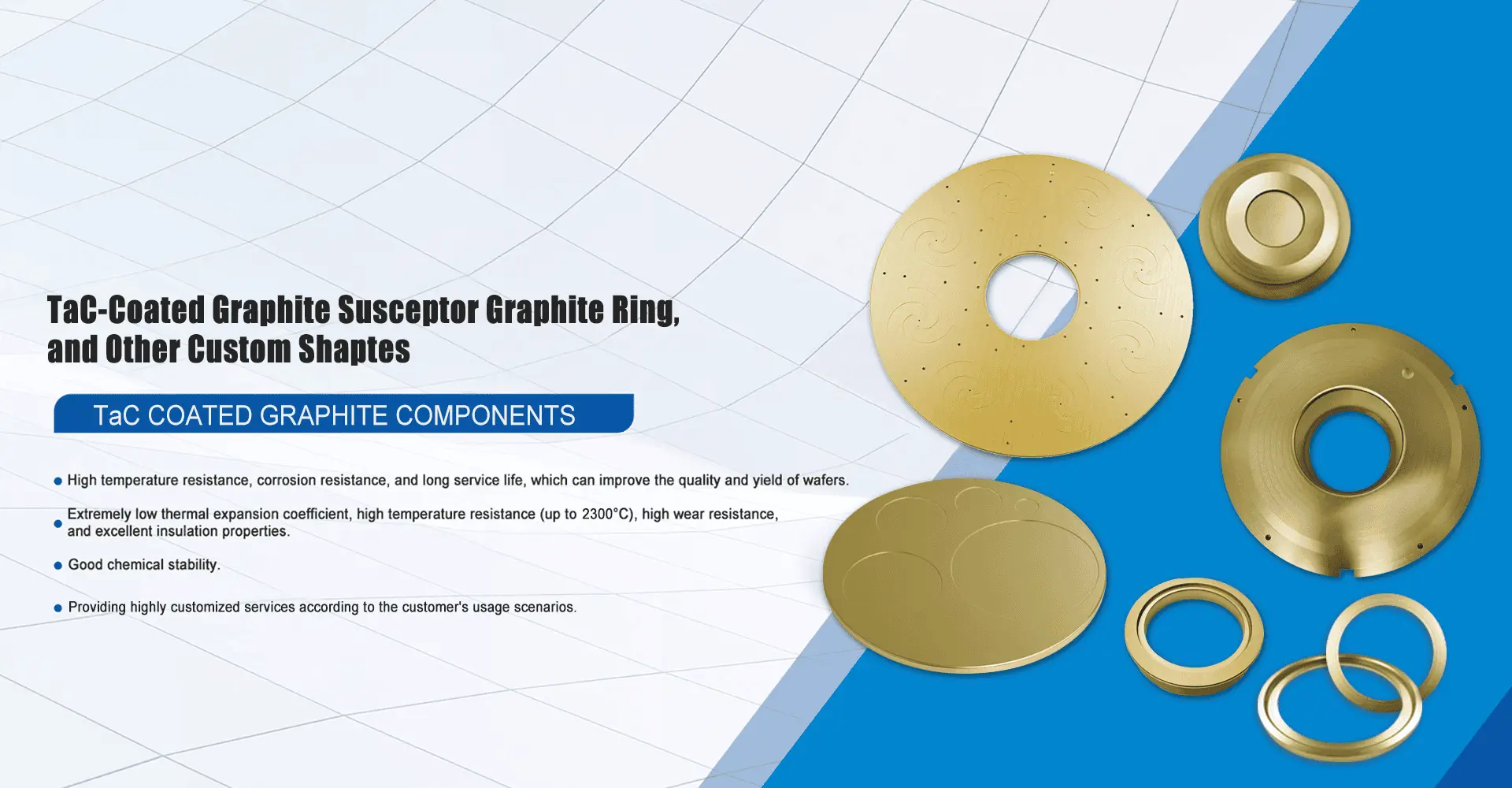

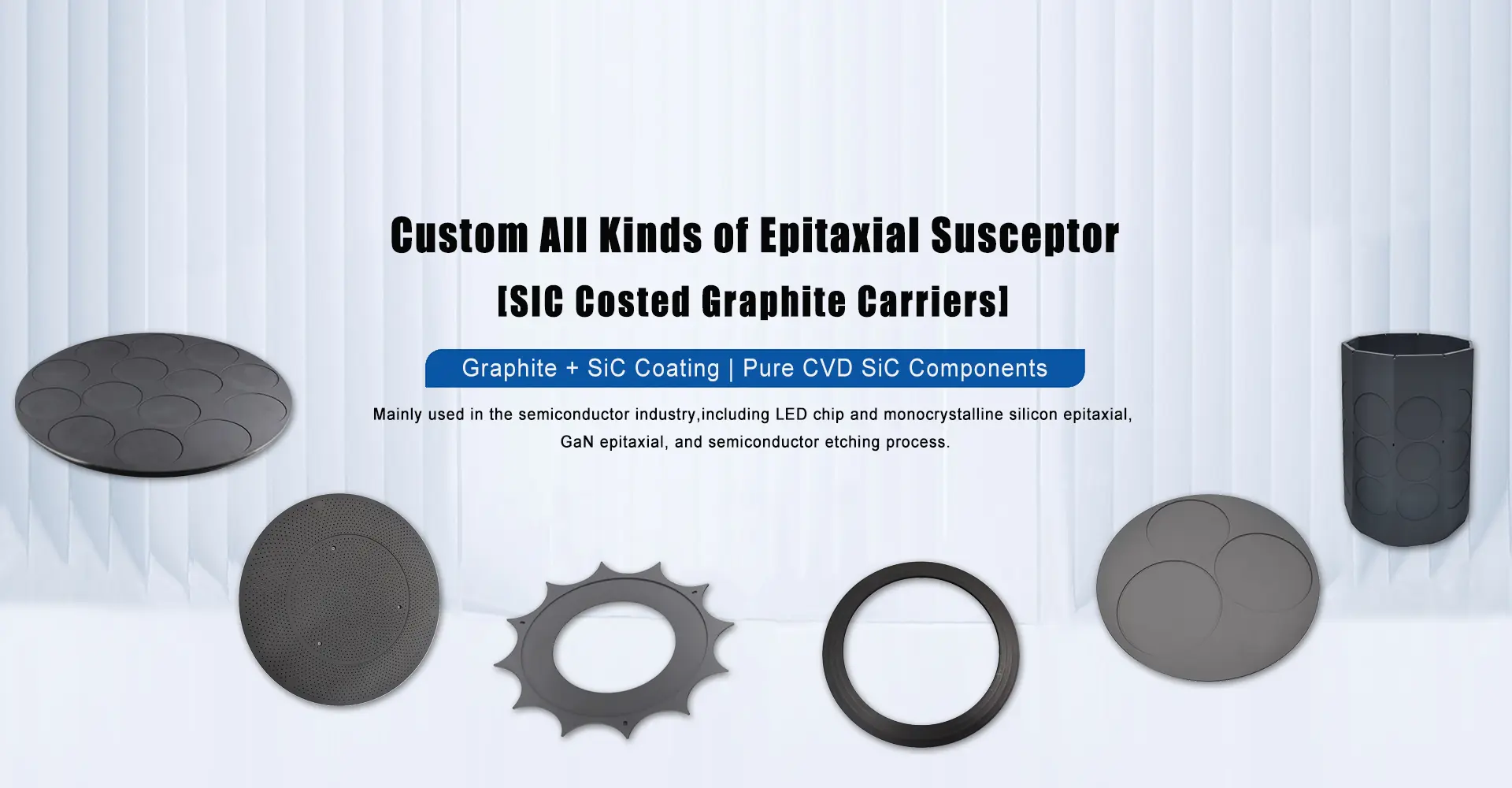

Semicera Semiconductor integrates R&D and production with dual research centers and three production bases, supporting 50 production lines and 200+ employees. Over 25% of the team is dedicated to R&D, emphasizing technology, production, sales, and operational management. Our products cater to the LED, IC integrated circuits, third-generation semiconductors, and photovoltaic industries. As a leading supplier of advanced semiconductor ceramics, we offer high-purity silicon carbide (SiC) ceramics, CVD SiC, and TaC coatings. Our main products include SiC-coated graphite susceptors, preheat rings, and TaC-coated diversion rings with purity levels below 5ppm, ensuring they meet customer requirements.