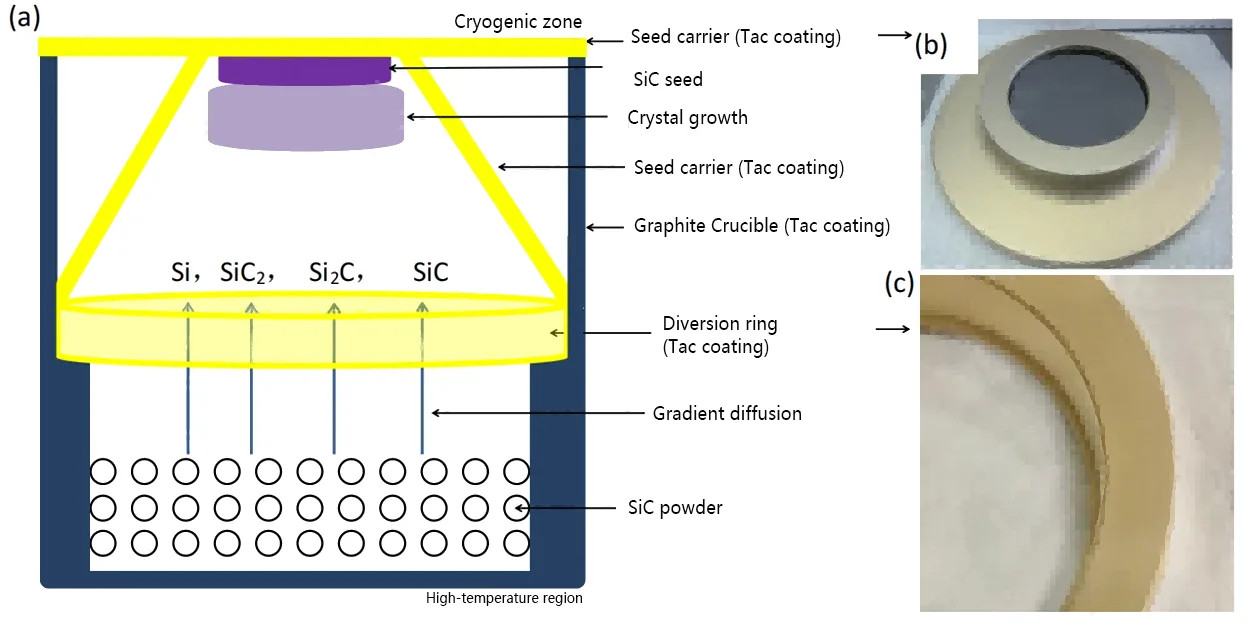

Semicera is Chinese leadingCVDTaC/SiCcoating factory.Elevate your equipment’s performance withSemicerahigh-performanceChemical Vapor Deposition (CVD)Tantalum Carbide (TaC) coated rings. Featuring superior thermal stability, chemical resistance, and low friction, these rings are tailor-made to withstand extreme conditions, making them ideal for aerospace, semiconductor, nuclear, and chemical industries.

Introducing Semicera premium custom Chemical Vapor Deposition (CVD) Tantalum Carbide (TaC) coated rings, engineered to perform under the most demanding industrial conditions. These rings are designed for applications requiring superior durability, heat resistance, and chemical stability.

Each custom CVD TaC coated ring undergoes rigorous quality control and testing to ensure it meets the highest industry standards and specific customer requirements. Semicera are committed to delivering reliable, high-performance products that exceed your expectations.

For more details, quotes, and customization options, please contact Semicera sales team. We are dedicated to providing you with professional service and support tailored to your specific

More sample