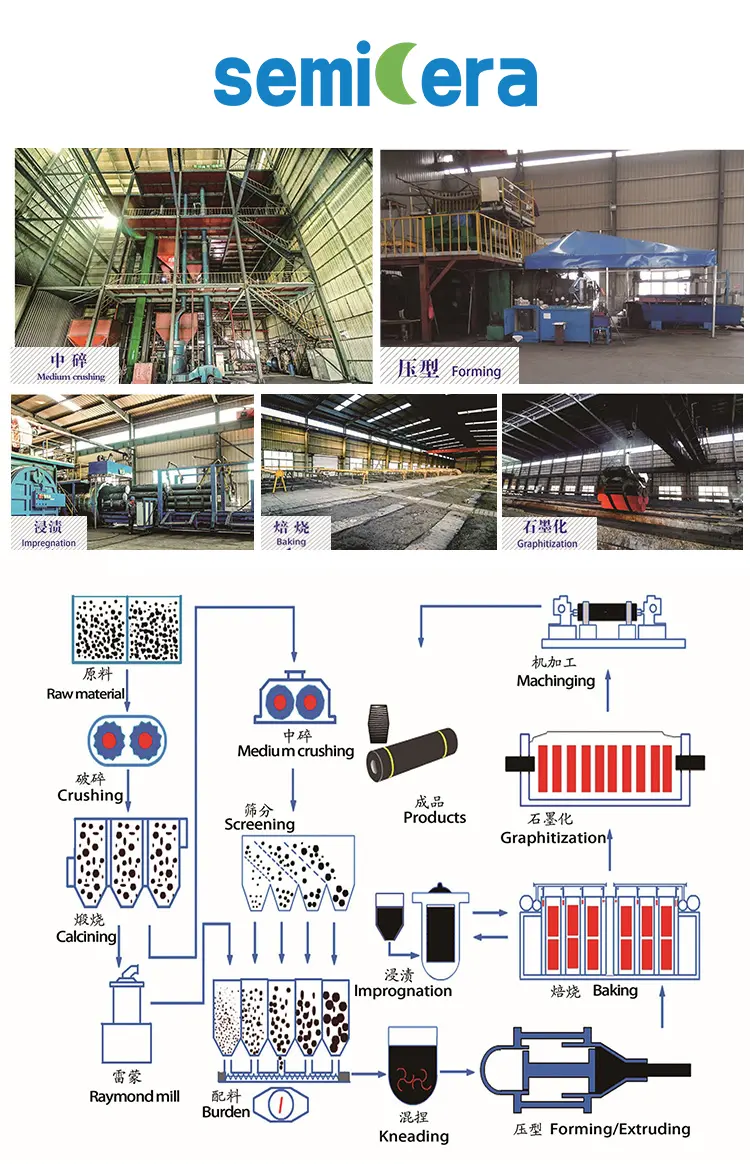

Semicera’s Graphite Rigid Felt for Vacuum Furnace is specifically engineered for high-performance use in vacuum furnace applications. Offering excellent thermal conductivity, chemical resistance, and structural stability, this high-quality graphite material ensures optimal heat management and durability. Ideal for industries such as metallurgy, semiconductor, and material processing, Semicera’s graphite rigid felt delivers reliable performance and efficiency under extreme conditions, making it the perfect solution for your vacuum furnace needs.

|

Nombre del producto |

Fieltro de grafito |

|

Composición química |

Fibra de carbono |

|

Densidad masiva |

0.12-0.14g/cm3 |

|

Contenido de carbono |

> = 99% |

|

Resistencia a la tracción |

0.14Mpa |

|

Thermal conductivity(1150℃) |

0.08 ~ 0.14W/mk |

|

Ceniza |

<= 0.005% |

|

Estrés aplastante |

8-10N/cm |

|

Espesor |

1-10mm |

|

Temperatura de procesamiento |

2500(℃) |

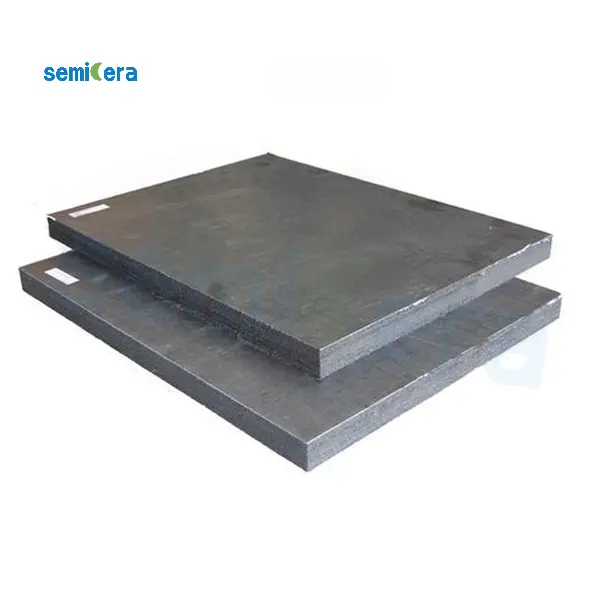

Volume Density (g/cm3): 0.22-0.28

Tensile Strength (Mpa): 2.5 (Deformation 5%)

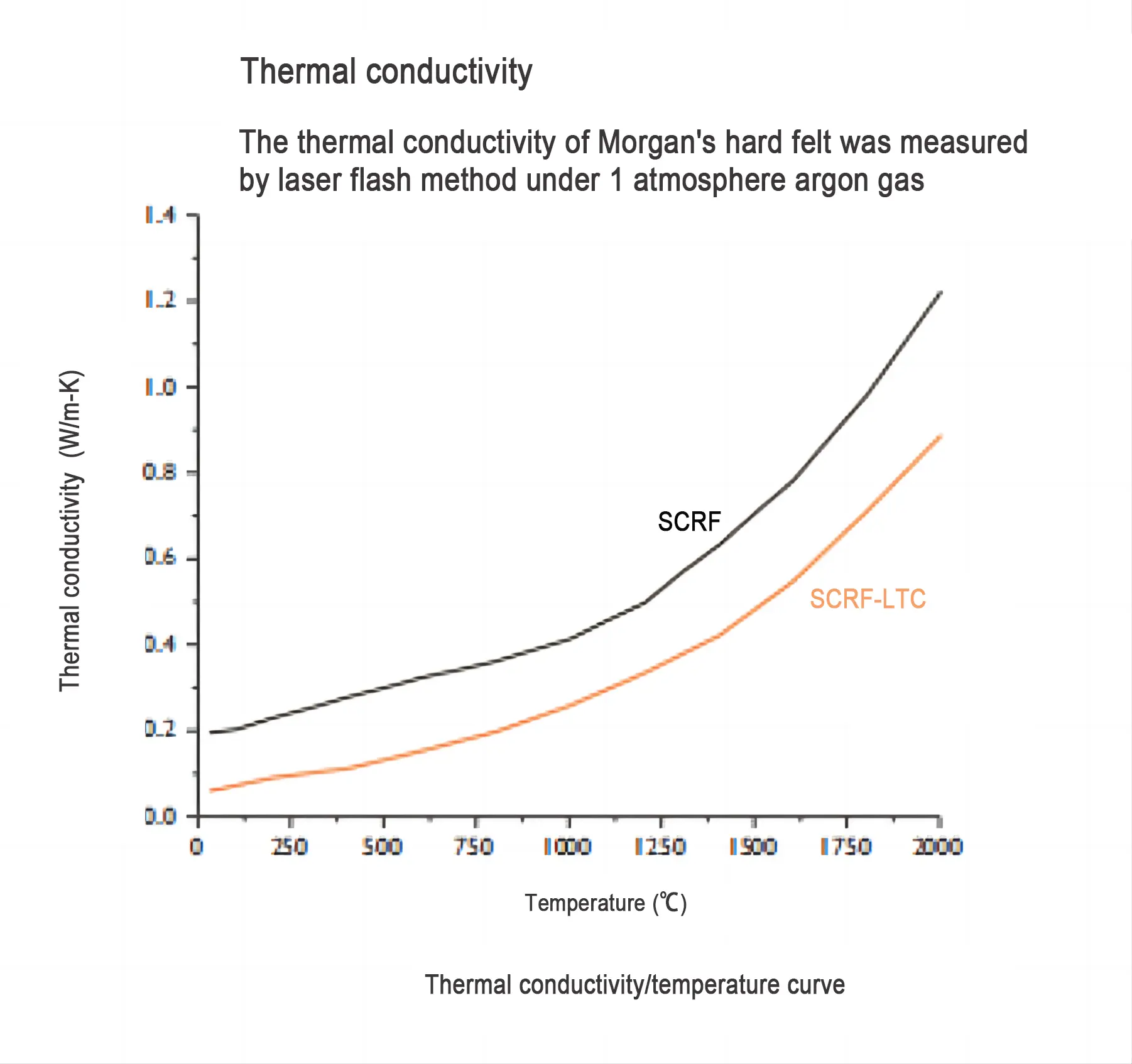

Thermal Conductivity (W/m.k): 0.15-0.25(25) 0.40-0.45(1400)

Specific Resistance (Ohm.cm): 0.18-0.22

Carbon Content (%): ≥99

Ash Content (%): ≤0.6

Moisture Absorption (%): ≤1.6

Purification Scale : Hight Purity

Processing Temperature : 1450-2000

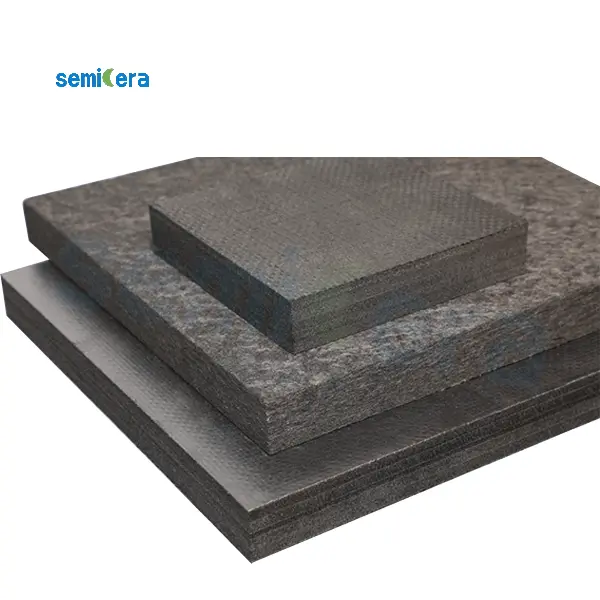

Actualmente hay cuatro grados disponibles para proporcionar productos en bruto o procesados.:

SCRF: Purified cured graphite fiber hard felt, heat treatment temperature above 1900℃

SCRF-P: Highly purified RGB hard felt

SCRF-LTC: Purified solidified graphite fiber hard felt, heat treatment temperature above 1900℃, with better thermal insulation performance

SCRF-LTC-P: Highly purified RGB-LTC hard felt

Tamaño disponible:

Placa: 1500*1800 (máximo) Espesor 20-200 mm

Tambor redondo: 1500*2000 (máximo) gruesos 20-150 mm

Tambor cuadrado: 1500*1500*2000 (máximo) Espesor 60-120 mm

Rango de temperatura aplicativo: 1250-2600

Fields of applications:

•Vacuum furnaces

•Inert gas furnaces

•Heat treatment (hardening, carbonization, brazing, etc.)

•Carbon fiber production

•Hard metal production

•Sintering applications

•Technical ceramic production

•CVD/PVD coasting