The Tantalum Carbide Coated Wafer Carrier by Semicera Semiconductor is engineered for high performance in semiconductor manufacturing. Featuring a robust tantalum carbide coating, it ensures exceptional wear resistance, high thermal stability, and superior protection in harsh environments. Ideal for MOCVD processes, this carrier enhances wafer processing efficiency, extends equipment lifespan, and delivers consistent results in critical applications.

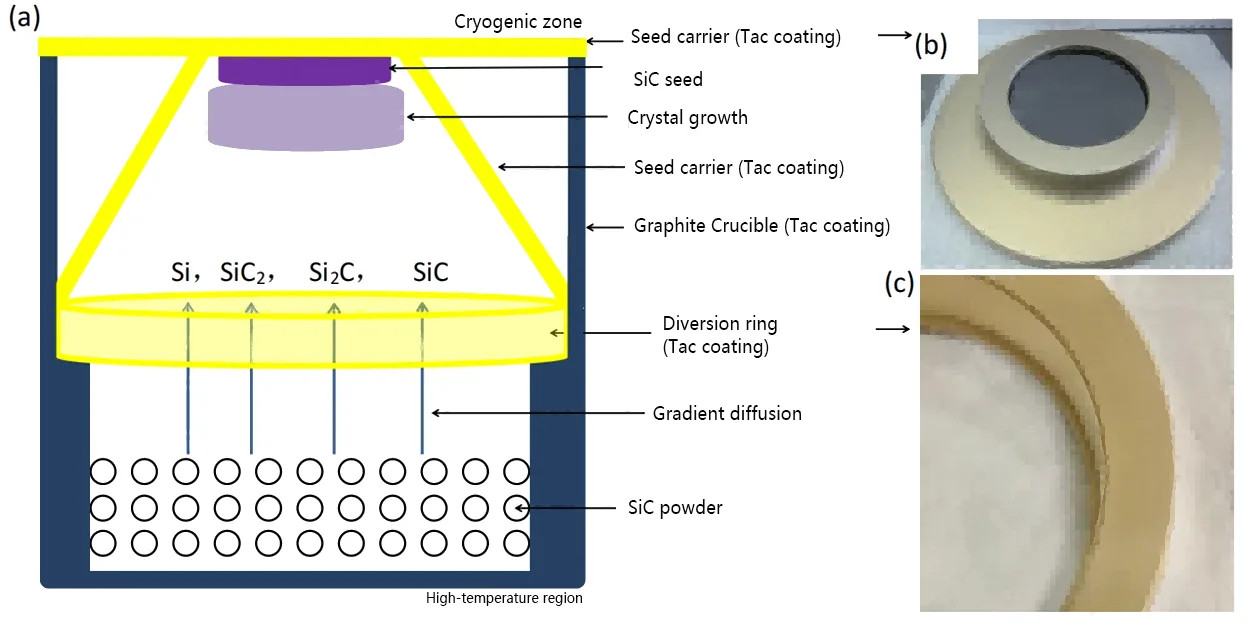

Semicera propose des revêtements de carbure de tantale (TAC) spécialisés pour divers composants et transporteurs. Semicera leading coating process enables tantalum carbide (TaC) coatings to achieve high purity, high temperature stability and high chemical tolerance, improving product quality of SIC/GAN crystals and EPI layers (Graphite coated TaC susceptor), and extending the life of key reactor components. The use of tantalum carbide TaC coating is to solve the edge problem and improve the quality of crystal growth, and Semicera has breakthrough solved the tantalum carbide coating technology (CVD), reaching the international advanced level.

Tantalum carbide coated wafer carriers are widely used in wafer processing and handling processes in semiconductor manufacturing processes. They provide stable support and protection to ensure the safety, accuracy and consistency of wafers during the manufacturing process. Tantalum carbide coatings can extend the service life of the carrier, reduce costs, and improve the quality and reliability of semiconductor products.

Description of tantalum carbide coated wafer carrier is as follows:

1. Material selection: Tantalum carbide is a material with excellent performance, high hardness, high melting point, corrosion resistance and excellent mechanical properties, so it is widely used in semiconductor manufacturing process.

2. Surface coating: Tantalum carbide coating is applied to the surface of wafer carrier through a special coating process to form a uniform and dense tantalum carbide coating. This coating can provide additional protection and wear resistance, while having good thermal conductivity.

3. Flatness and precision: Tantalum carbide coated wafer carrier has a high degree of flatness and precision, ensuring the stability and accuracy of wafers during the manufacturing process. The flatness and finish of the carrier surface are critical to ensure the quality and performance of the wafer.

4. Temperature stability: Tantalum carbide coated wafer carriers can maintain stability in high temperature environments without deformation or loosening, ensuring the stability and consistency of wafers in high temperature processes.

5. Corrosion resistance: Tantalum carbide coatings have excellent corrosion resistance, can resist the erosion of chemicals and solvents, and protect the carrier from liquid and gas corrosion.

Moreover, Semicera’s TaC-coated products exhibit a longer service life and greater high-temperature resistance compared to SiC coatings. Laboratory measurements have demonstrated that our TaC coatings can consistently perform at temperatures up to 2300 degrees Celsius for extended periods. Below are some examples of our samples: