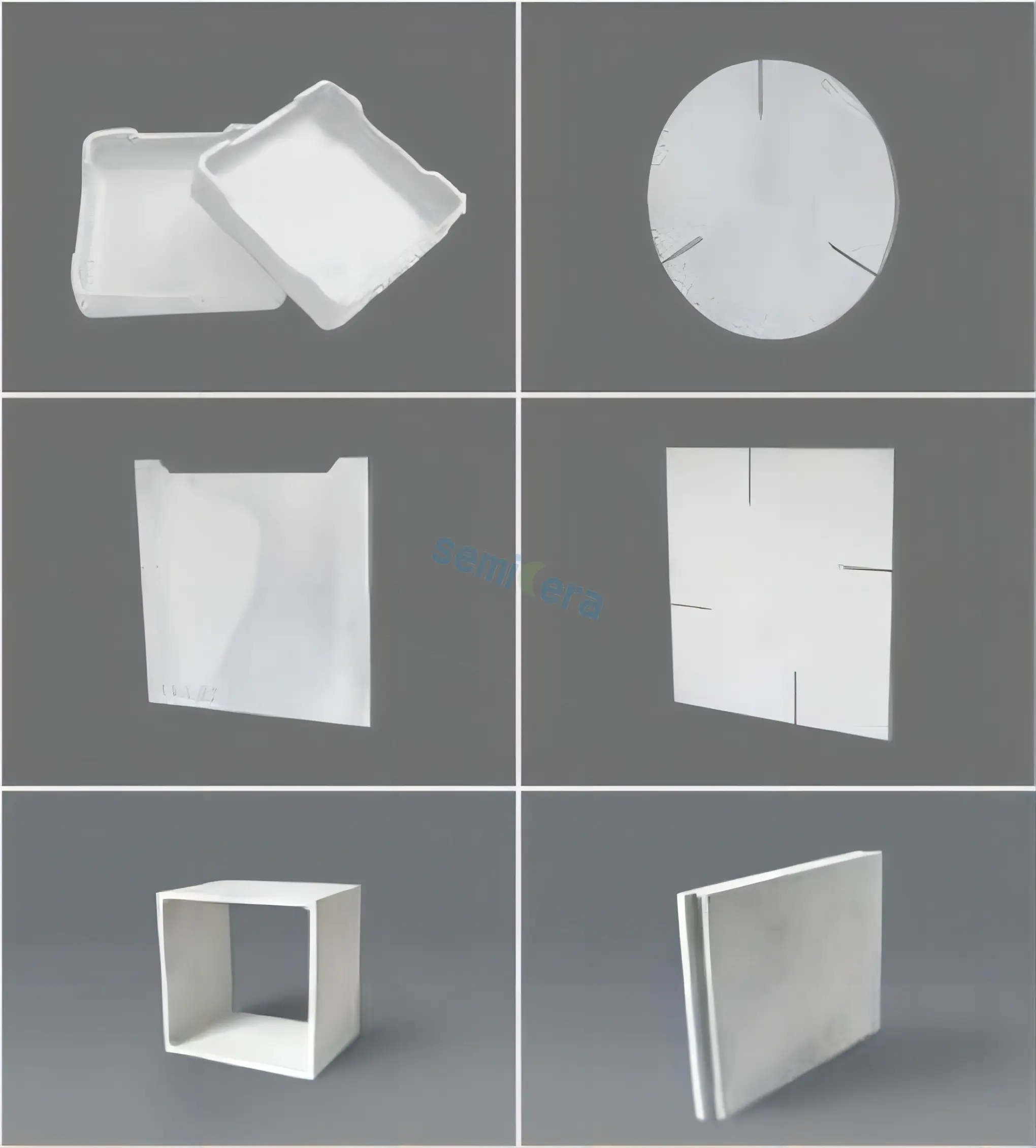

Semicera Energy Technology Co., Ltd. is a leading supplier specializing in wafer and advanced semiconductor consumables.We are dedicated to providing high-quality, reliable, and innovative products to semiconductor manufacturing,photovoltaic industryand other related fields.Our product line includes SiC/TaC coated graphite products and ceramic products, encompassing various materials such as silicon carbide, silicon nitride, and aluminum oxide and etc.As a trusted supplier, we understand the importance of consumables in the manufacturing process, and we are committed to delivering products that meet the highest quality standards to fulfill our customers’ needs.

Le nitrure de silicium combiné avec le four à carbure de silicium a les caractéristiques d'une résistance à haute température, d'une bonne résistance aux chocs thermiques, d'une déformation facile, d'une résistance à l'oxydation, d'une résistance à la corrosion, d'une bonne conductivité thermique, etc.

|

Article |

Index de brick |

Spécification du four |

Index du produit en forme |

|

Porosité apparente(%) |

<16 |

<16 |

<14 |

|

Densité en vrac(g/cm3) |

2 2.65 |

2 2.65 |

2 2.68 |

|

Résistance à la compression à température ambiante(MPA) |

2 160 |

2 170 |

2 180 |

|

Résistance à la flexion à température ambiante(1400X:) MPA |

2 40 |

2 45 |

2 45 |

|

Résistance à la flexion à haute température(1400r ) MPA |

2 50 |

2 50 |

2 50 |

|

Coefficient de dilatation thermique(110CTC) xiovc |

<4.18 |

<4.18 |

<4.18 |

|

Conductivité thermique(1100C) |

216 |

2 16 |

216 |

|

Réfractaires(°C ) |

1800 |

1800 |

1800 |

|

0,2 MPa Adoucissement de la température sous charge(X:) |

1600 |

1600 |

> 1700 |

|

Température de fonctionnement maximale (°C) |

1550 |

1550 |

1550 |

Les produits sont largement utilisés dans la roue de mouture en céramique, les produits en aluminium élevé, la boule de porcelaine en aluminium, le four industriel, la céramique électronique, la porcelaine électrique haute tension, les articles sanitaires, la porcelaine quotidienne, les alliages de nitrure et la céramique en mousse et d'autres industries.

The wear resistance of Si3N4-SiC material is 3.13 times that of wear-resistant steel (Crl5Mo3), and the weight is only 1/3 of that of wear-resistant steel (Crl5Mo3).

The corrosion resistance quality reduction values of Si3N4-SiC and calcium carbide and alumina in various solutions are as follows:

|

Test solution |

Temperature(”C) |

Si3N4-SiC |

Common ceramics |

Aluminium carbide |

Aluminium oxide |

|

98 %Sulfuric acid |

100 |

1.8 |

55.0 |

> 1000 |

65,0 |

|

50 %Sodium hydroxide |

100 |

2,5 |

> 1000 |

5.0 |

75.0 |

|

53 %Hydrofluoric acid |

25 |

< 0.2 |

7.9 |

8.0 |

20,0 |

|

85 %Phosphoric acid |

100 |

< 0.2 |

8.8 |

55.0 |

> 1000 |

|

70 %Nitric acid |

100 |

< 0.2 |

0.5 |

> 1000 |

7,0 |

|

45 %Potassium hydroxide |

100 |

< 0.2 |

> 1000 |

3.0 |

60,0 |

|

25 %Hydrochloric acid |

70 |

< 0.2 |

0.9 |

85.0 |

72,0 |

|

10% Hydrofluoric acid +57% Nitric acid

|

25 |

< 0.2 |

> 1000 |

> 1000 |

16,0 |