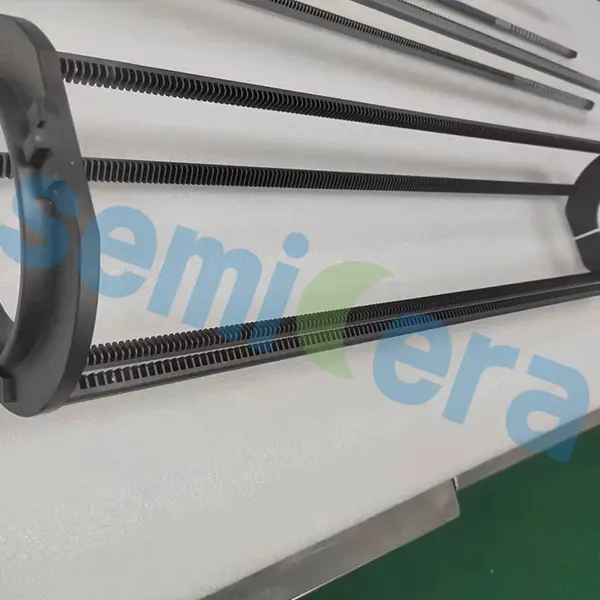

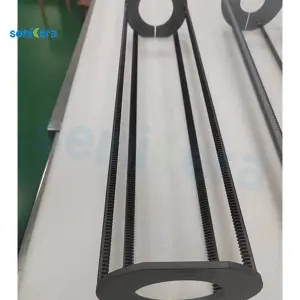

Semicera Energy Technology Co., Ltd. is a high-tech enterprise established in China, We are professional supply Semiconductor industry recrystallized silicon carbide crystal boat nufacturer and supplier.

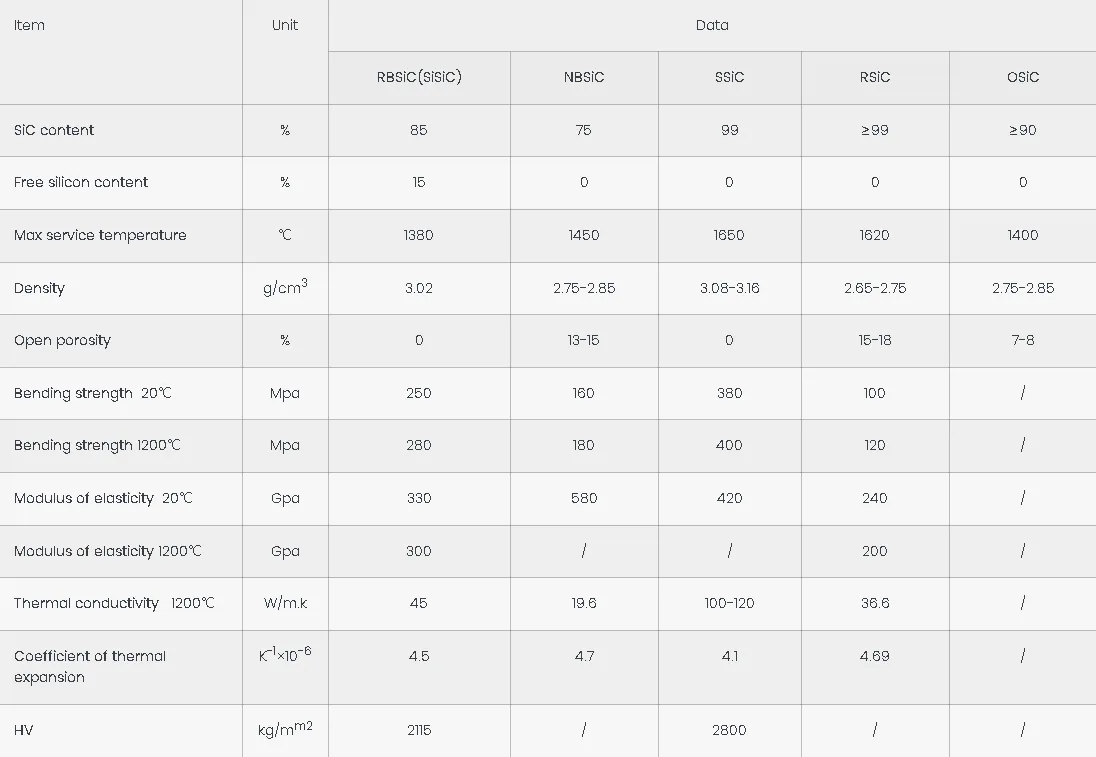

Properties of recrystallized silicon carbide

Recrystallized silicon carbide (R-SiC) is a high-performance material with hardness second only to diamond, which is formed at a high temperature above 2000℃. It retains many excellent properties of SiC, such as high temperature strength, strong corrosion resistance, excellent oxidation resistance, good thermal shock resistance and so on.

● Excellent mechanical properties. Recrystallized silicon carbide has higher strength and stiffness than carbon fiber, high impact resistance, can play a good performance in extreme temperature environments, can play a better counterbalance performance in a variety of situations. In addition, it also has good flexibility and is not easily damaged by stretching and bending, which greatly improves its performance.

● High corrosion resistance. Recrystallized silicon carbide has high corrosion resistance to a variety of media, can prevent the erosion of a variety of corrosive media, can maintain its mechanical properties for a long time, has a strong adhesion, so that it has a longer service life. In addition, it also has good thermal stability, can adapt to a certain range of temperature changes, improve its application effect.

● Sintering does not shrink. Because the sintering process does not shrink, no residual stress will cause deformation or cracking of the product, and parts with complex shapes and high precision can be prepared.

|

Matériel |

R-Sic |

|

Utiliser la températureTempérature de travail (°C) |

1600°C ( Atmosphère d'oxydationEnvironnement oxydant) 1700°C ( Restaurer l'atmosphèreRéduction de l'environnement) |

|

SiccontenuContenu SIC (%) |

> 99 |

|

gratuitSi contenuContenu SI gratuit (%) |

< 0.1 |

|

Densité de volumeDensité en vrac (g / cm3) |

2.60-2.70 |

|

PorositéPorosité apparente (%) |

< 16 |

|

Résistance à la compressionForce d'écrasement (MPA) |

> 600 |

|

Résistance à la flexion à température ambianteRésistance à la flexion à froid (MPA) |

80-90 (20°C) |

|

Résistance à la flexion à haute températureRésistance à la flexion chaude (MPA) |

90-100 (1400°C) |

|

Coefficient de dilatation thermique Thermal expansion coefficient @1500°C (10-6/°C) |

4.70 |

|

Conductivité thermiqueConductivité thermique @ 1200°C (W / M•K) |

23 |

|

Module de YoungModule élastique (GPA) |

240 |

|

Résistance aux chocs thermiquesRésistance aux chocs thermiques |

très bienExtrêmement bon |