SemiceraTaC Coating Chuck, the cutting-edge vacuum chuck equipped with TaC coatings, specifically designed for semiconductor furnaces.Semicerais committed to providing quality products at competitive prices, we look forward to becoming your long-term partner in China.

Seminer TaC Coating Chuck, the cutting-edge vacuum chuck equipped with TaC coatings, specifically designed for semiconductor furnaces. Engineered to meet the rigorous demands of modern semiconductor manufacturing processes, this innovative technology sets a new standard for precision, reliability, and longevity.

At the heart of semiconductor fabrication lies the critical need for precise control and stability during processing. The TaC Coating Chuck addresses this need by integrating advanced TaC (Tantalum Carbide) coatings onto its surface, ensuring exceptional thermal stability, durability, and resistance to chemical corrosion. This unique combination of materials not only enhances the chuck’s performance but also extends its operational lifespan, providing consistent results over countless cycles.

One of the key advantages of the TaC Coating Chuck is its ability to maintain a high level of vacuum integrity throughout the entire processing cycle. By effectively minimizing outgassing and contamination, this technology ensures the purity and quality of the semiconductor materials, resulting in superior device performance and reliability.

Moreover, the TaC Coating Chuck offers unmatched versatility, accommodating a wide range of semiconductor substrates with varying sizes and geometries. The customizable design of the TaC Coating Chuck allows for seamless integration into existing semiconductor furnace systems, minimizing downtime and maximizing productivity.

With the TaC Coating Chuck, semiconductor manufacturers can achieve higher throughput, improved yield, and reduced overall costs. Whether in research laboratories or high-volume production facilities, this advanced technology empowers semiconductor professionals to push the boundaries of innovation while maintaining strict quality standards.

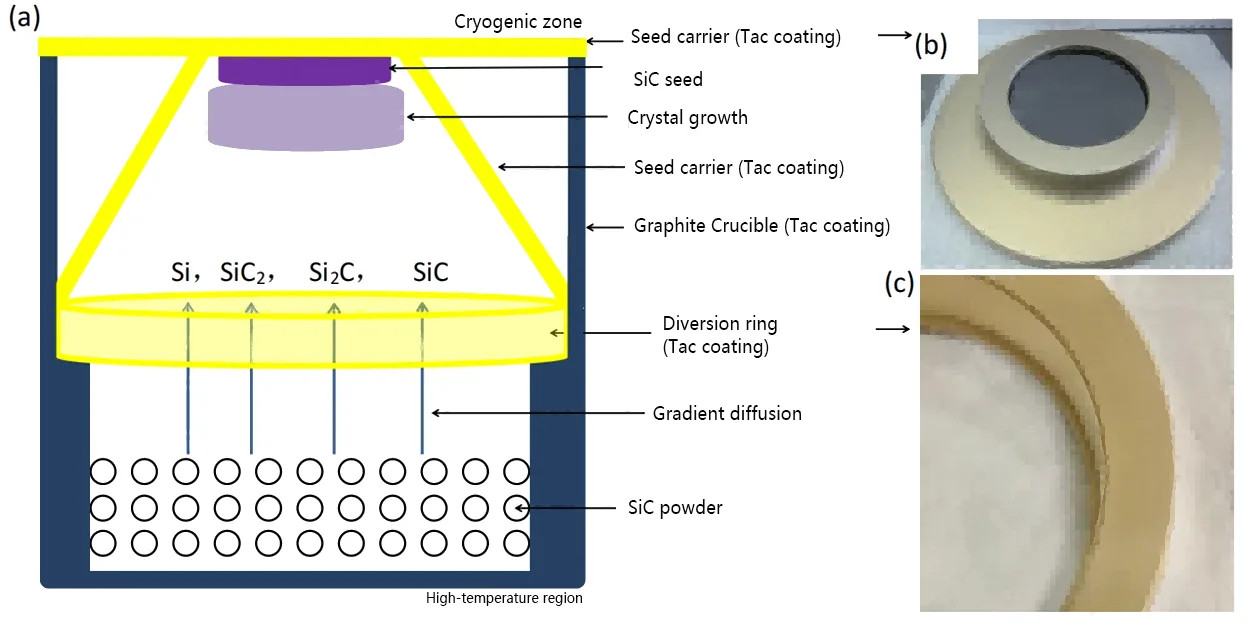

Moreover, Semicera’s TaC-coated products exhibit a longer service life and greater high-temperature resistance compared to SiC coatings. Laboratory measurements have demonstrated that our TaC coatings can consistently perform at temperatures up to 2300 degrees Celsius for extended periods. Below are some examples of our samples: