Semicera’s Graphite Rigid Felt for Vacuum Furnace is specifically engineered for high-performance use in vacuum furnace applications. Offering excellent thermal conductivity, chemical resistance, and structural stability, this high-quality graphite material ensures optimal heat management and durability. Ideal for industries such as metallurgy, semiconductor, and material processing, Semicera’s graphite rigid felt delivers reliable performance and efficiency under extreme conditions, making it the perfect solution for your vacuum furnace needs.

|

Nome prodotto |

Felimento della grafite |

|

Composizione chimica |

Fibra di carbonio |

|

Densità di massa |

0.12-0.14g/cm3 |

|

Contenuto di carbonio |

> = 99% |

|

Resistenza alla trazione |

0.14Mpa |

|

Thermal conductivity(1150℃) |

0,08 ~ 0,14W/MK |

|

Cenere |

<= 0,005% |

|

Stress schiacciante |

8-10N/cm |

|

Spessore |

1-10mm |

|

Temperatura di elaborazione |

2500(℃) |

Volume Density (g/cm3): 0.22-0.28

Tensile Strength (Mpa): 2.5 (Deformation 5%)

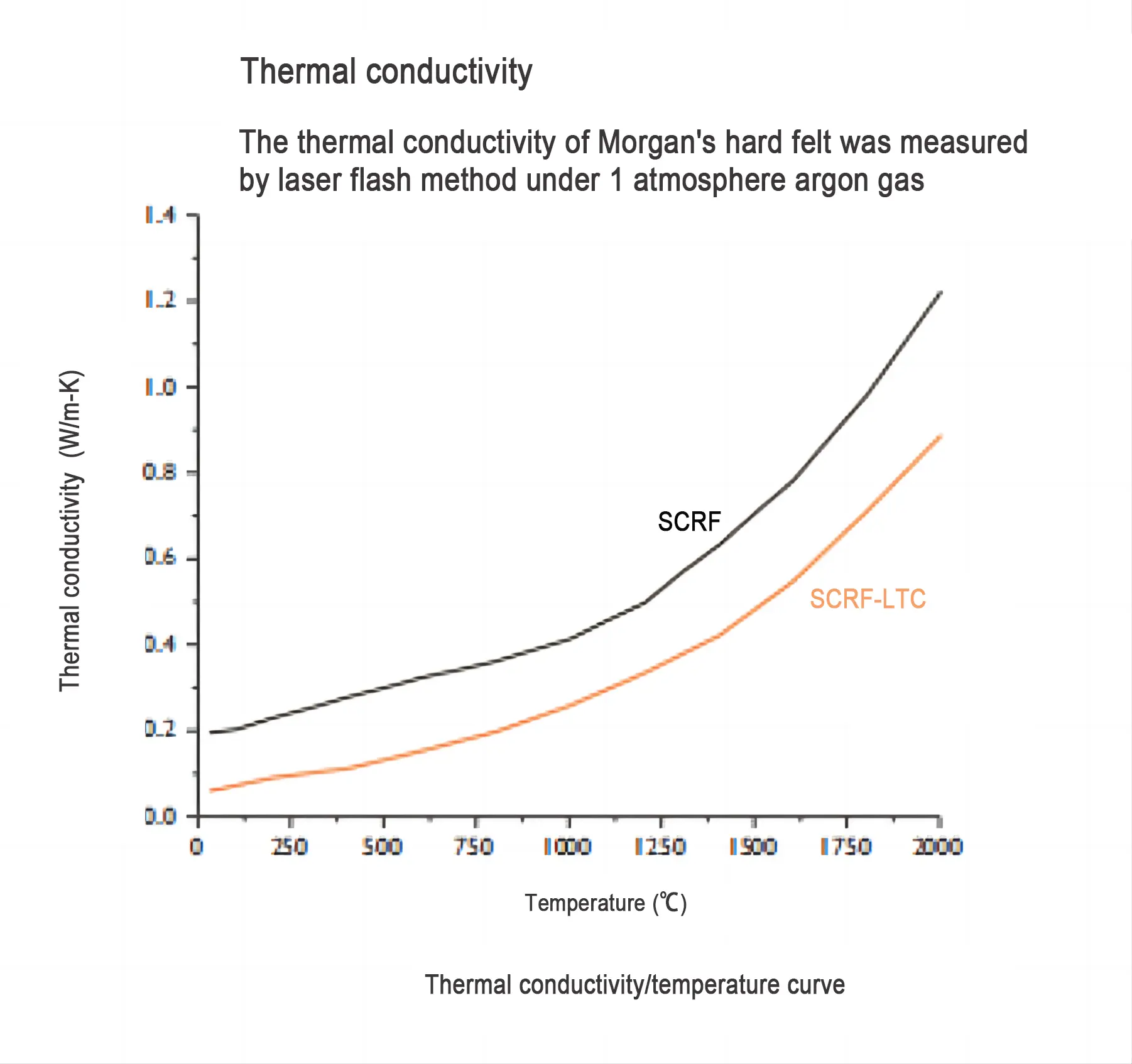

Thermal Conductivity (W/m.k): 0.15-0.25(25) 0.40-0.45(1400)

Specific Resistance (Ohm.cm): 0.18-0.22

Carbon Content (%): ≥99

Ash Content (%): ≤0.6

Moisture Absorption (%): ≤1.6

Purification Scale : Hight Purity

Processing Temperature : 1450-2000

Attualmente sono disponibili quattro voti per fornire prodotti grezzi o trasformati:

SCRF: Purified cured graphite fiber hard felt, heat treatment temperature above 1900℃

SCRF-P: Highly purified RGB hard felt

SCRF-LTC: Purified solidified graphite fiber hard felt, heat treatment temperature above 1900℃, with better thermal insulation performance

SCRF-LTC-P: Highly purified RGB-LTC hard felt

Dimensione disponibile:

Piastra: 1500*1800 (max) spessore 20-200mm

Drum rotondo: 1500*2000 (max) Spessive 20-150mm

Drum quadrato: 1500*1500*2000 (max) spessore 60-120mm

Intervallo di temperatura applicativo: 1250-2600

Fields of applications:

•Vacuum furnaces

•Inert gas furnaces

•Heat treatment (hardening, carbonization, brazing, etc.)

•Carbon fiber production

•Hard metal production

•Sintering applications

•Technical ceramic production

•CVD/PVD coasting