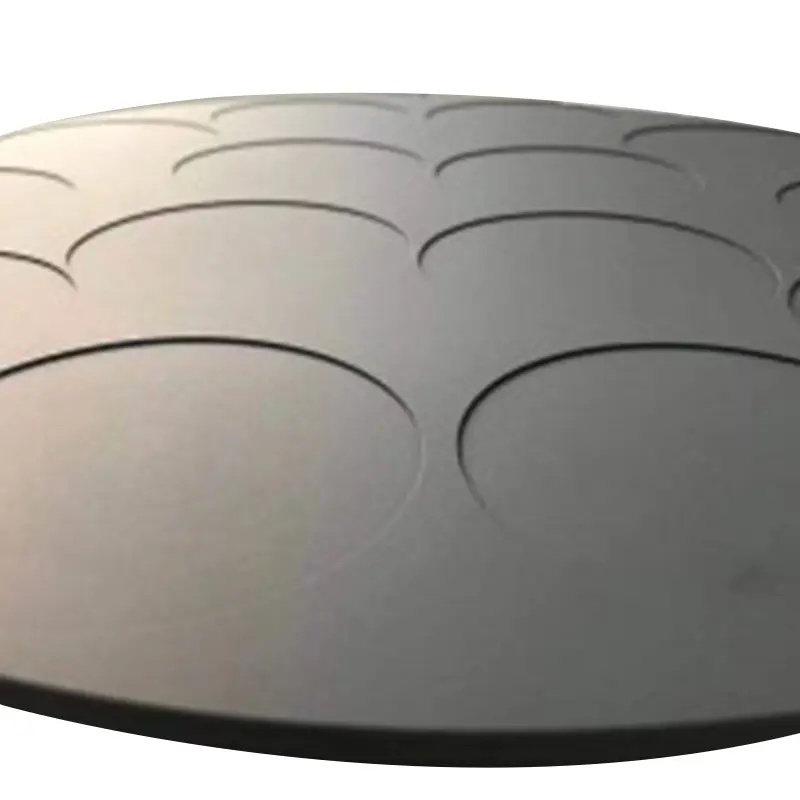

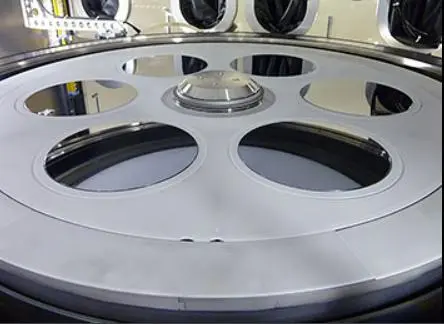

Semicera offers a comprehensive range of susceptors and graphite components designed for various epitaxy reactors.

Through strategic partnerships with industry-leading OEMs, extensive materials expertise, and advanced manufacturing capabilities, Semicera delivers tailored designs to meet the specific requirements of your application. Our commitment to excellence ensures that you receive optimal solutions for your epitaxy reactor needs.

CVD-SiC coating has the characteristics of uniform structure, compact material, high temperature resistance, oxidation resistance, high purity, acid&alkali resistance and organic reagent, with stable physical and chemical properties.

Compared with high-purity graphite materials, graphite begins to oxidize at 400C, which will cause a loss of powder due to oxidation, resulting in environmental pollution to peripheral devices and vacuum chambers, and increase impurities of high-purity environment.

However, SiC coating can maintain physical and chemical stability at 1600 degrees, It is widely used in modern industry, especially in semiconductor industry.

Our company provides SiC coating process services by CVD method on the surface of graphite, ceramics and other materials, so that special gases containing carbon and silicon react at high temperature to obtain high purity SiC molecules, molecules deposited on the surface of the coated materials, forming SIC protective layer. The SIC formed is firmly bonded to the graphite base, giving the graphite base special properties, thus making the surface of the graphite compact, Porosity-free, high temperature resistance, corrosion resistance and oxidation resistance.

1. Alta purezza SIC con la grafite rivestita

2. Resistenza al calore superiore e uniformità termica

3. cristallo SiC fine rivestito per una superficie liscia

4. alta durata contro la pulizia chimica

| Sic-cvd | ||

| Densità | (G/CC) | 3.21 |

| Forza di flessione | (MPA) | 470 |

| Espansione termica | (10-6/K) | 4 |

| Conducibilità termica | (W/MK) | 300 |

Capacità di fornitura:

10000 pezzi/pezzi al mese

Imballaggio e consegna:

Imballaggio: imballaggio standard e forte

Poly Bag + Box + Carton + Pallet

Porta:

Ningbo/Shenzhen/Shanghai

Tempi di consegna:

| Quantità (pezzi) | 1 – 1000 | >1000 |

| Est. Tempo (giorni) | 15 | To be negotiated |