Semicorex is known as one of the most professional Tantalum carbide Coating Diversion Ring manufacturers and suppliers in China. Customized Tantalum carbide Coating Diversion Ring is not only advanced but also durable. Besides, we we have own factory and we also support bulk packaging. Welcome to place an order.

Semicera provides specialized tantalum carbide (TaC) coatings for various components and carriers. Semicera leading coating process enables tantalum carbide (TaC) coatings to achieve high purity, high temperature stability and high chemical tolerance, improving product quality of SIC/GAN crystals and EPI layers (Graphite coated TaC susceptor), and extending the life of key reactor components. The use of tantalum carbide TaC coating is to solve the edge problem and improve the quality of crystal growth, and Semicera has breakthrough solved the tantalum carbide coating technology (CVD), reaching the international advanced level.

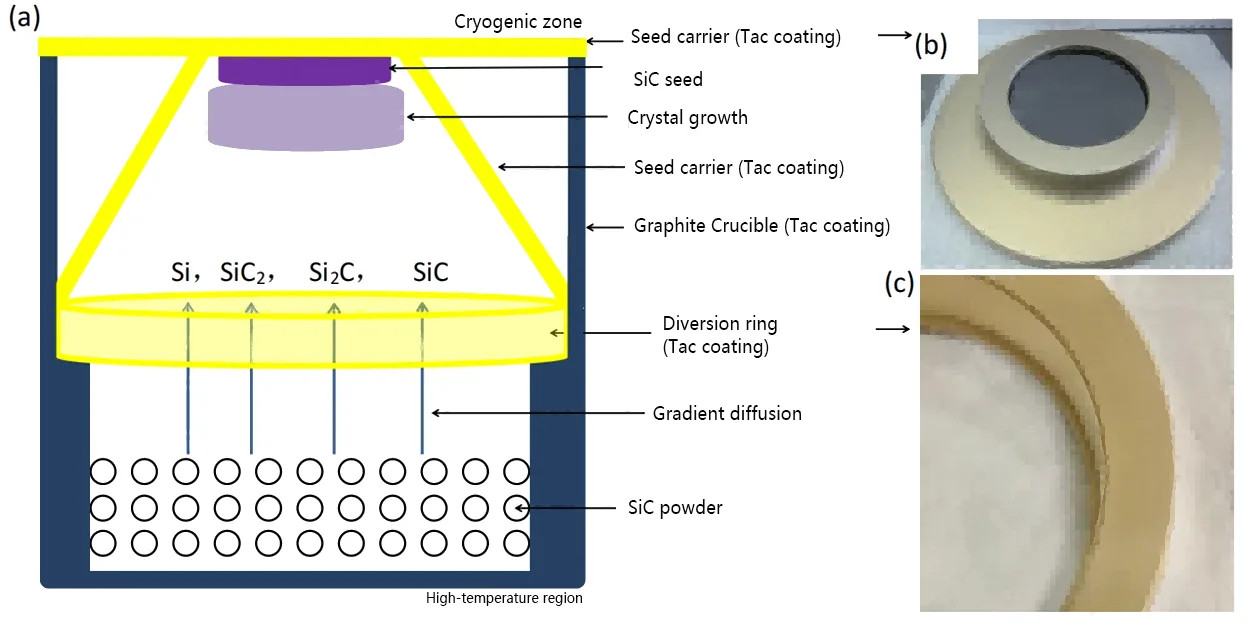

After years of development, Semicera has conquered the technology of CVD TaC with the joint efforts of the R&D department. Defects are easy to occur in the growth process of SiC wafers, but after using TaC, the difference is significant. Below is a comparison of wafers with and without TaC, as well as Simicera’ parts for single crystal growth.

Moreover, Semicera’s TaC-coated products exhibit a longer service life and greater high-temperature resistance compared to SiC coatings. Laboratory measurements have demonstrated that our TaC coatings can consistently perform at temperatures up to 2300 degrees Celsius for extended periods. Below are some examples of our samples: