You often hear about the importance of precision and efficiency in the semiconductor industry. CVD-SiC paddles play a vital role in achieving these goals. Their unique properties make them indispensable in many manufacturing processes. For example:

- The market for Silicon Carbide Cantilever Paddles is growing rapidly, reflecting their increasing demand in semiconductor production.

- Historical trends show a consistent rise in their usage, proving their reliability.

- Experts predict continued growth due to advancements in technology and the demand for high-performance materials.

These factors highlight why CVD-SiC paddle for the semiconductor industry is a game-changer in modern manufacturing.

キーテイクアウト

- CVD-SiC paddles stay stable in high heat, perfect for semiconductors.

- They resist chemicals and rust, staying strong and clean in tough conditions.

- Using CVD-SiC paddles saves money over time with less upkeep.

- Check your factory needs to see if CVD-SiC paddles fit your work.

- Taking care of CVD-SiC paddles helps them last longer and work better.

Benefits of CVD-SiC Paddle for the Semiconductor Industry

Exceptional Thermal Stability

You need materials that can withstand extreme temperatures in semiconductor manufacturing. CVD-SiC paddles excel in this area. They maintain their structural integrity even when exposed to high heat. This stability ensures consistent performance during processes like wafer handling and deposition. Unlike other materials, they resist warping or cracking under thermal stress. This reliability makes them a preferred choice for high-temperature applications.

High Chemical and Oxidation Resistance

Semiconductor processes often involve harsh chemicals and reactive gases. CVD-SiC paddles offer exceptional resistance to these conditions. Their chemical inertness minimizes reactions with corrosive substances, ensuring smooth operations. Additionally, their oxidation resistance prevents material degradation during prolonged exposure to high temperatures.

- Key advantages include:

- Maintaining structural integrity at extreme temperatures.

- Reducing reactions with corrosive gases.

- Preventing degradation from oxidation.

These properties make CVD-SiC paddles ideal for environments where chemical stability is critical.

Superior Durability and Longevity

Durability is essential in semiconductor manufacturing. CVD-SiC paddles stand out due to their robust construction. They resist wear and tear, even in demanding conditions. This longevity reduces the need for frequent replacements, saving you time and money. Their superior durability ensures consistent performance over extended periods, making them a cost-effective solution for your operations.

Enhanced Process Efficiency and Yield

In semiconductor manufacturing, efficiency and yield are critical for success. You need tools that can optimize these factors, and CVD-SiC paddles excel in this area. Their unique properties contribute to smoother operations, fewer defects, and higher-quality outputs.

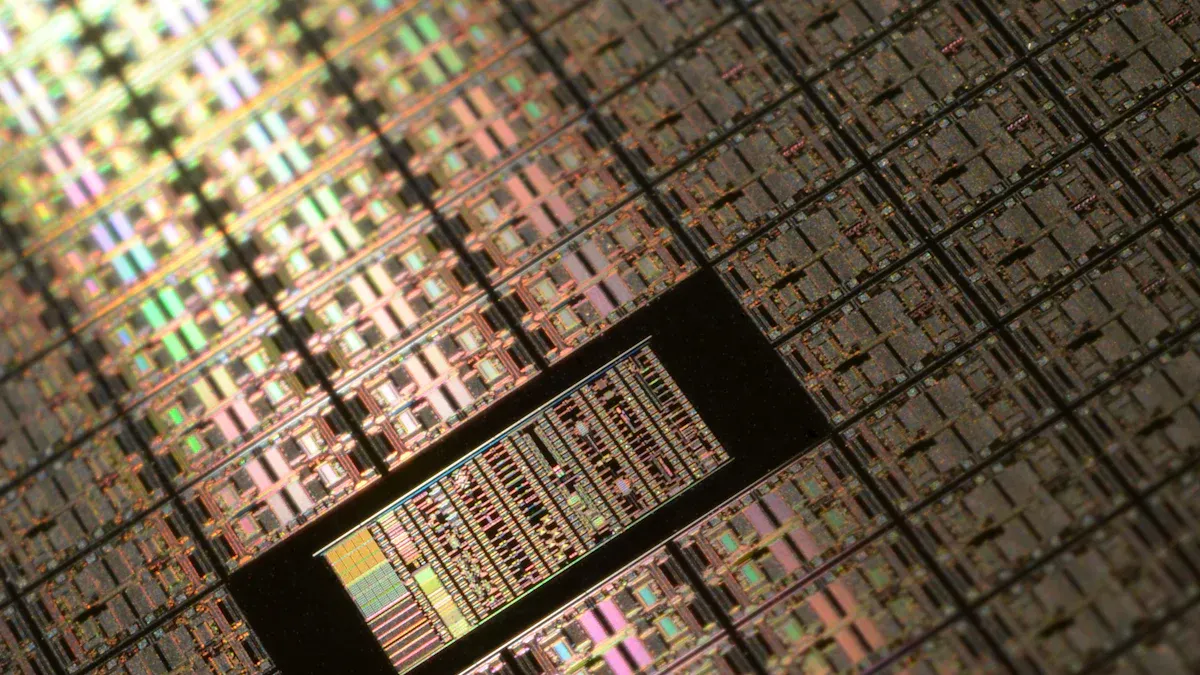

One way CVD-SiC paddles enhance efficiency is by supporting advanced crystal growth techniques like Physical Vapor Transport (PVT). This method improves the purity and quality of silicon carbide wafers. Fewer defects mean better electrical conductivity and higher yields. Additionally, additive manufacturing allows for the creation of complex paddle geometries. These designs optimize fluid dynamics, improving cooling efficiency during high-temperature processes.

Smart materials used in CVD-SiC paddles also play a role. These materials can adjust their properties in real-time, providing better thermal management. This adaptability extends the paddle’s lifespan and ensures consistent performance.

Here’s a closer look at how these innovations impact efficiency and yield:

| Innovation/Technique | Impact on Efficiency and Yield |

|---|---|

| Advanced crystal growth techniques (PVT) | Enhances purity and quality of SiC wafers, reducing defects and improving electrical conductivity. |

| Additive manufacturing | Enables complex geometries for optimized fluid dynamics, improving cooling efficiency. |

| Smart materials | Adjust properties in real-time for better thermal management, extending paddle lifespan. |

By leveraging these advancements, you can achieve higher throughput and better product quality. The CVD-SiC Paddle for the semiconductor industry not only boosts efficiency but also ensures a more reliable and cost-effective manufacturing process.

Limitations and Challenges of CVD-SiC Paddle for the Semiconductor Industry

High Initial Investment Costs

When considering CVD-SiC paddles, you may notice their higher upfront costs compared to other materials. This is due to the advanced manufacturing processes and premium raw materials required to produce them. While these paddles offer long-term benefits, the initial expense can be a barrier for smaller operations or those with limited budgets.

Tip: Evaluate the long-term savings from reduced maintenance and extended lifespan to justify the initial investment.

Compatibility Issues with Certain Processes

CVD-SiC paddles perform exceptionally well in many semiconductor applications. However, they may not be suitable for every process. Some manufacturing setups require materials with specific properties that CVD-SiC paddles might not fully meet. For instance, processes involving extremely low temperatures or unique chemical reactions might demand alternative solutions.

To ensure compatibility, you should assess your process requirements carefully. Consulting with experts or suppliers can help you determine if CVD-SiC paddles align with your operational needs.

Maintenance and Handling Considerations

Proper maintenance and handling are crucial for maximizing the lifespan of CVD-SiC paddles. These paddles are durable, but mishandling during installation or routine operations can lead to damage. You must train your staff to handle them with care and follow recommended maintenance practices.

Regular inspections can help you identify potential issues early. For example, checking for surface wear or contamination ensures optimal performance. By prioritizing proper care, you can avoid unnecessary downtime and maintain consistent results in your processes.

Key Applications of CVD-SiC Paddle for the Semiconductor Industry

High-Temperature Processes

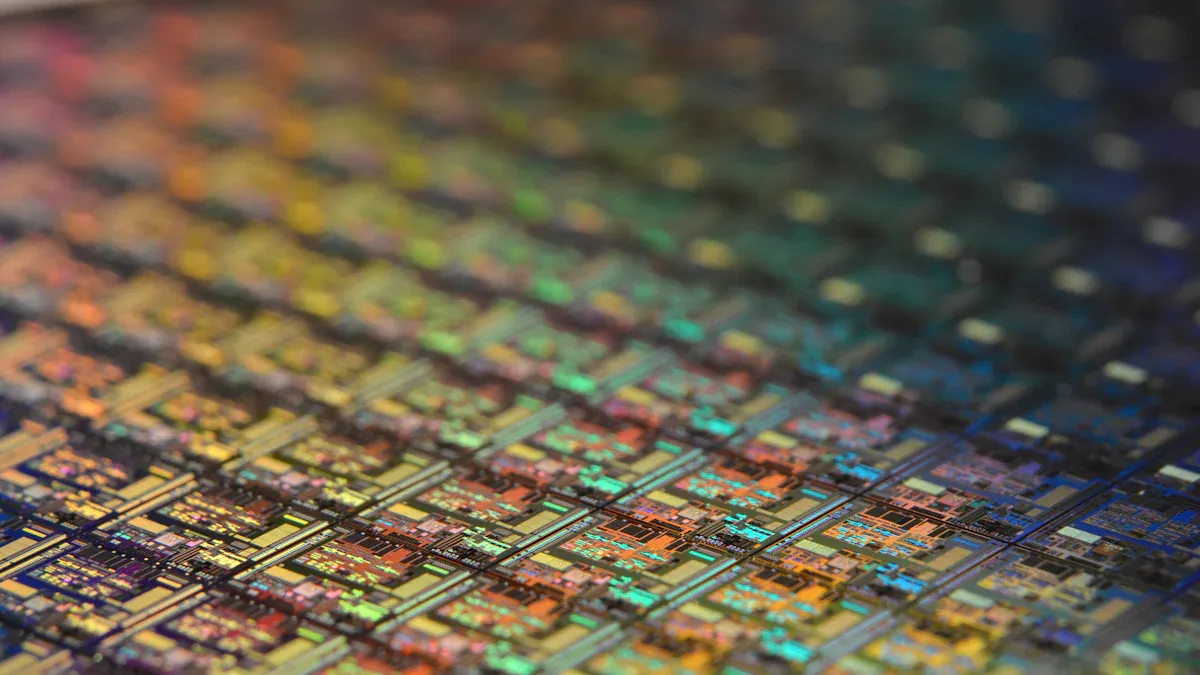

In semiconductor manufacturing, high-temperature processes demand materials that can endure extreme heat without compromising performance. CVD-SiC paddles excel in these conditions. Their thermal conductivity reaches an impressive 304.9 W/mK at 28°C (301 K), ensuring efficient heat transfer. This property helps maintain process stability and prevents overheating. Additionally, the total impurity level of CVD-SiC is less than 3.5 ppm by weight. This low impurity level ensures minimal contamination, which is critical for producing high-quality wafers.

You can rely on these paddles for processes like epitaxy and annealing, where consistent thermal performance is essential. Their ability to resist thermal shock and maintain structural integrity makes them a reliable choice for high-temperature applications.

Corrosive or Harsh Chemical Environments

Semiconductor processes often involve exposure to corrosive chemicals and reactive gases. CVD-SiC paddles thrive in these environments due to their exceptional chemical resistance. They do not react with most acids, bases, or oxidizing agents, ensuring long-term durability. This resistance minimizes the risk of contamination and reduces the need for frequent replacements.

For example, in processes like chemical vapor deposition (CVD) or etching, these paddles maintain their performance even when exposed to aggressive chemicals. Their oxidation resistance further enhances their suitability for such applications. By choosing CVD-SiC paddles, you can ensure smooth operations in chemically demanding environments.

Precision-Driven Applications in Wafer Handling

Precision is crucial in wafer handling, as even minor errors can lead to defects. CVD-SiC paddles offer the dimensional stability and rigidity needed for precise operations. Their lightweight yet robust design allows for accurate positioning and movement of wafers during manufacturing.

These paddles are particularly useful in processes requiring tight tolerances, such as lithography or thin-film deposition. Their ability to maintain shape and alignment under stress ensures consistent results. By using CVD-SiC paddles, you can achieve higher yields and better product quality in precision-driven applications.

Factors to Consider When Choosing CVD-SiC Paddle for the Semiconductor Industry

Process-Specific Requirements and Conditions

Before selecting a CVD-SiC paddle, you need to evaluate your specific manufacturing processes. Each semiconductor process has unique requirements, such as temperature ranges, chemical exposure, and precision needs. For example, high-temperature applications demand paddles with excellent thermal stability, while processes involving corrosive chemicals require superior chemical resistance.

You should also consider the compatibility of the paddle with your existing equipment. Some tools may require custom paddle designs to ensure seamless integration. Consulting with your supplier can help you identify the best options for your setup.

Tip: Create a checklist of your process conditions to match them with the paddle’s properties. This approach ensures you select the most suitable option.

Cost-Benefit Analysis for Long-Term Use

While the initial cost of a CVD-SiC paddle may seem high, you should focus on its long-term benefits. These paddles offer exceptional durability, reducing the need for frequent replacements. Over time, this durability translates into significant cost savings.

Additionally, their ability to enhance process efficiency and yield can offset the upfront investment. Higher yields mean fewer defects and better product quality, which can improve your profitability. When evaluating costs, consider factors like reduced downtime, lower maintenance expenses, and improved output quality.

Note: Investing in high-quality paddles can save you money in the long run by minimizing operational disruptions.

Evaluating ROI and Performance Metrics

To determine the value of a CVD-SiC paddle for the semiconductor industry, you should analyze its return on investment (ROI). Start by tracking key performance metrics, such as yield improvement, defect reduction, and equipment uptime. These metrics provide a clear picture of the paddle’s impact on your operations.

You can also compare the paddle’s performance with alternative materials. Look for measurable improvements in efficiency, durability, and product quality. By quantifying these benefits, you can justify the investment and make informed decisions.

Pro Tip: Use data from pilot tests or case studies to predict the paddle’s performance in your specific applications.

CVD-SiC Paddle for the semiconductor industry offers unmatched benefits in demanding environments. You gain advantages like high thermal stability and chemical resistance, which improve process reliability. However, their effectiveness depends on your specific needs. Factors like cost and compatibility play a crucial role in determining their suitability. Evaluating your process requirements thoroughly ensures you make the right choice. By understanding their strengths and aligning them with your goals, you can maximize their value in your operations.

よくある質問

What makes CVD-SiC paddles unique compared to other materials?

CVD-SiC paddles offer unmatched thermal stability, chemical resistance, and durability. These properties ensure reliable performance in high-temperature and corrosive environments. Their lightweight design also supports precision-driven applications, making them ideal for semiconductor manufacturing.

Can CVD-SiC paddles improve wafer quality?

Yes! Their advanced thermal conductivity and low impurity levels enhance wafer purity during processes like epitaxy. This reduces defects and improves electrical conductivity, resulting in higher-quality wafers.

Are CVD-SiC paddles suitable for all semiconductor processes?

Not all processes benefit equally. High-temperature and chemically demanding applications are ideal for CVD-SiC paddles. Evaluate your specific process requirements to ensure compatibility and optimal performance.

How do I maintain CVD-SiC paddles for long-term use?

Handle them carefully during installation and operations. Regular inspections for wear or contamination help maintain performance. Proper training for staff ensures safe handling and extends the paddle’s lifespan.

What factors should I consider before investing in CVD-SiC paddles?

Focus on your process needs, cost-benefit analysis, and expected ROI. Assess thermal stability, chemical resistance, and compatibility with your equipment. Consult suppliers for tailored solutions.