Semicera Energy Technology Co., Ltd. is a leading supplier specializing in wafer and advanced semiconductor consumables.We are dedicated to providing high-quality, reliable, and innovative products to semiconductor manufacturing,photovoltaic industryand other related fields.Our product line includes SiC/TaC coated graphite products and ceramic products, encompassing various materials such as silicon carbide, silicon nitride, and aluminum oxide and etc.As a trusted supplier, we understand the importance of consumables in the manufacturing process, and we are committed to delivering products that meet the highest quality standards to fulfill our customers’ needs.

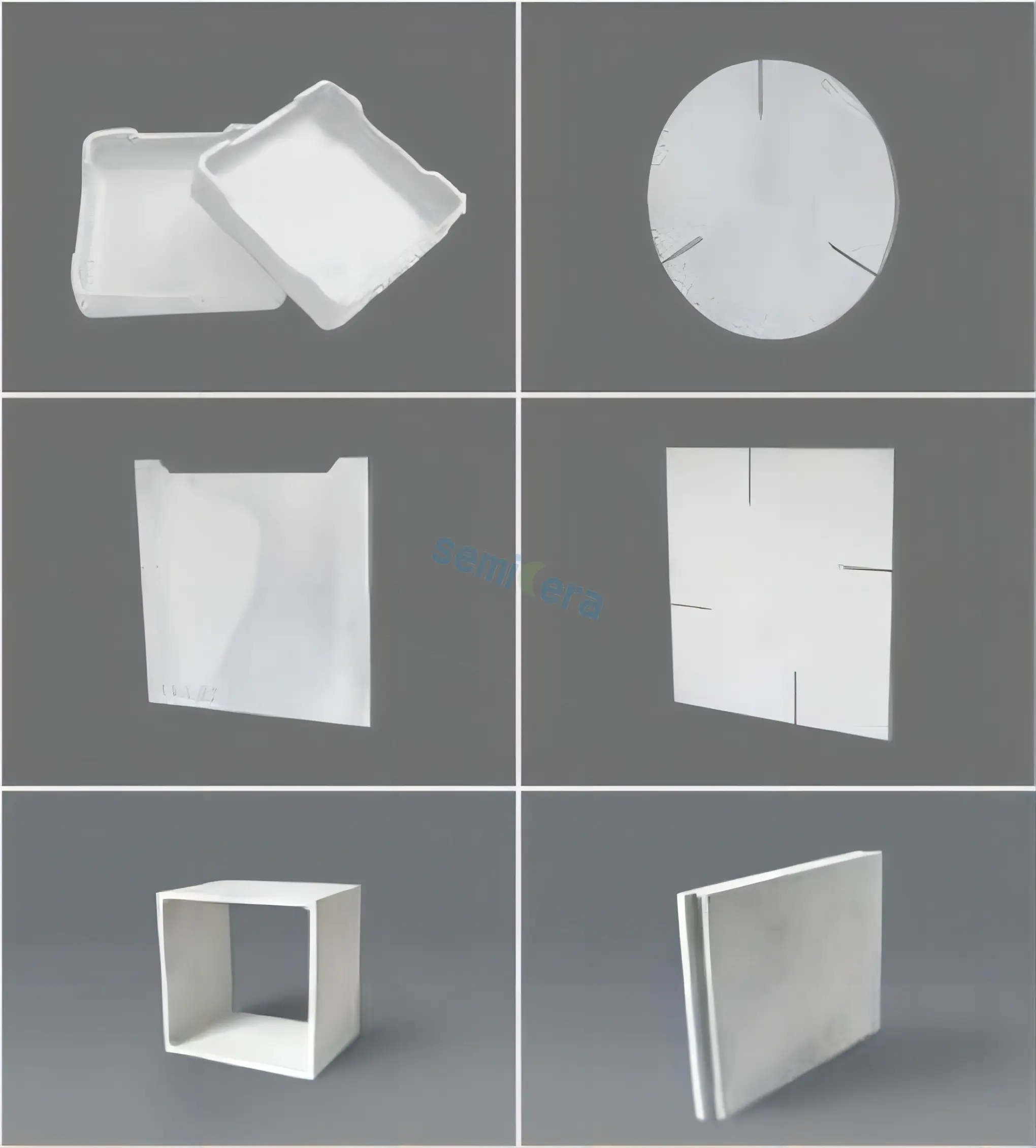

Silicon nitride combined with silicon carbide kiln has the characteristics of high temperature strength, good thermal shock resistance, easy deformation, oxidation resistance, corrosion resistance, good thermal conductivity and so on.

|

목 |

Firebrick index |

Kiln specification |

Index of shaped product |

|

Apparent porosity(%) |

<16 |

<16 |

<14 |

|

벌크 밀도(g/cm3) |

2 2.65 |

2 2.65 |

2 2.68 |

|

Compressive strength at room temperature(MPa) |

2 160 |

2 170 |

2 180 |

|

Bending strength at room temperature(1400X:) MPa |

2 40 |

2 45 |

2 45 |

|

High temperature bending strength(1400r ) MPa |

2 50 |

2 50 |

2 50 |

|

Coefficient of thermal expansion(110CTC) xioVC |

<4.18 |

<4.18 |

<4.18 |

|

열전도율(1100C) |

216 |

2 16 |

216 |

|

Refractories(°C ) |

1800 |

1800 |

1800 |

|

0.2 MPa Softening temperature under load(X:) |

1600 |

1600 |

> 1700 |

|

Maximum operating temperature (°C) |

1550 |

1550 |

1550 |

The products are widely used in ceramic grinding wheel, high aluminum products, aluminum porcelain ball, industrial kiln, electronic ceramic, high voltage electric porcelain, sanitary ware, daily porcelain, nitride alloy and foam ceramics and other industries.

The wear resistance of Si3N4-SiC material is 3.13 times that of wear-resistant steel (Crl5Mo3), and the weight is only 1/3 of that of wear-resistant steel (Crl5Mo3).

The corrosion resistance quality reduction values of Si3N4-SiC and calcium carbide and alumina in various solutions are as follows:

|

Test solution |

Temperature(”C) |

Si3N4-SiC |

Common ceramics |

Aluminium carbide |

Aluminium oxide |

|

98 %Sulfuric acid |

100 |

1.8 |

55.0 |

> 1000 |

65,0 |

|

50 %Sodium hydroxide |

100 |

2,5 |

> 1000 |

5.0 |

75.0 |

|

53 %Hydrofluoric acid |

25 |

< 0.2 |

7.9 |

8.0 |

20,0 |

|

85 %Phosphoric acid |

100 |

< 0.2 |

8.8 |

55.0 |

> 1000 |

|

70 %Nitric acid |

100 |

< 0.2 |

0.5 |

> 1000 |

7,0 |

|

45 %Potassium hydroxide |

100 |

< 0.2 |

> 1000 |

3.0 |

60,0 |

|

25 %Hydrochloric acid |

70 |

< 0.2 |

0.9 |

85.0 |

72,0 |

|

10% Hydrofluoric acid +57% Nitric acid

|

25 |

< 0.2 |

> 1000 |

> 1000 |

16,0 |