Semicera’s High Purity Graphite Rigid Felt is a premium material engineered for high-temperature applications, delivering exceptional thermal conductivity, chemical resistance, and mechanical strength. Perfect for industries such as semiconductors, electronics, and energy, this high-purity graphite felt ensures reliable performance in demanding environments. Trust Semicera for superior solutions in heat management and material performance.

|

제품 이름 |

흑연 펠트 |

|

화학 성분 |

탄소 섬유 |

|

벌크 밀도 |

0.12-0.14g/cm3 |

|

탄소 함량 |

> = 99% |

|

인장 강도 |

0.14Mpa |

|

Thermal conductivity(1150℃) |

0.08 ~ 0.14W/MK |

|

금연 건강 증진 협회 |

<= 0.005% |

|

분쇄 스트레스 |

8-10N/cm |

|

두께 |

1-10mm |

|

처리 온도 |

2500(℃) |

부피 밀도 (g/cm3) : 0.22-0.28

인장 강도 (MPA) : 2.5 (변형 5%)

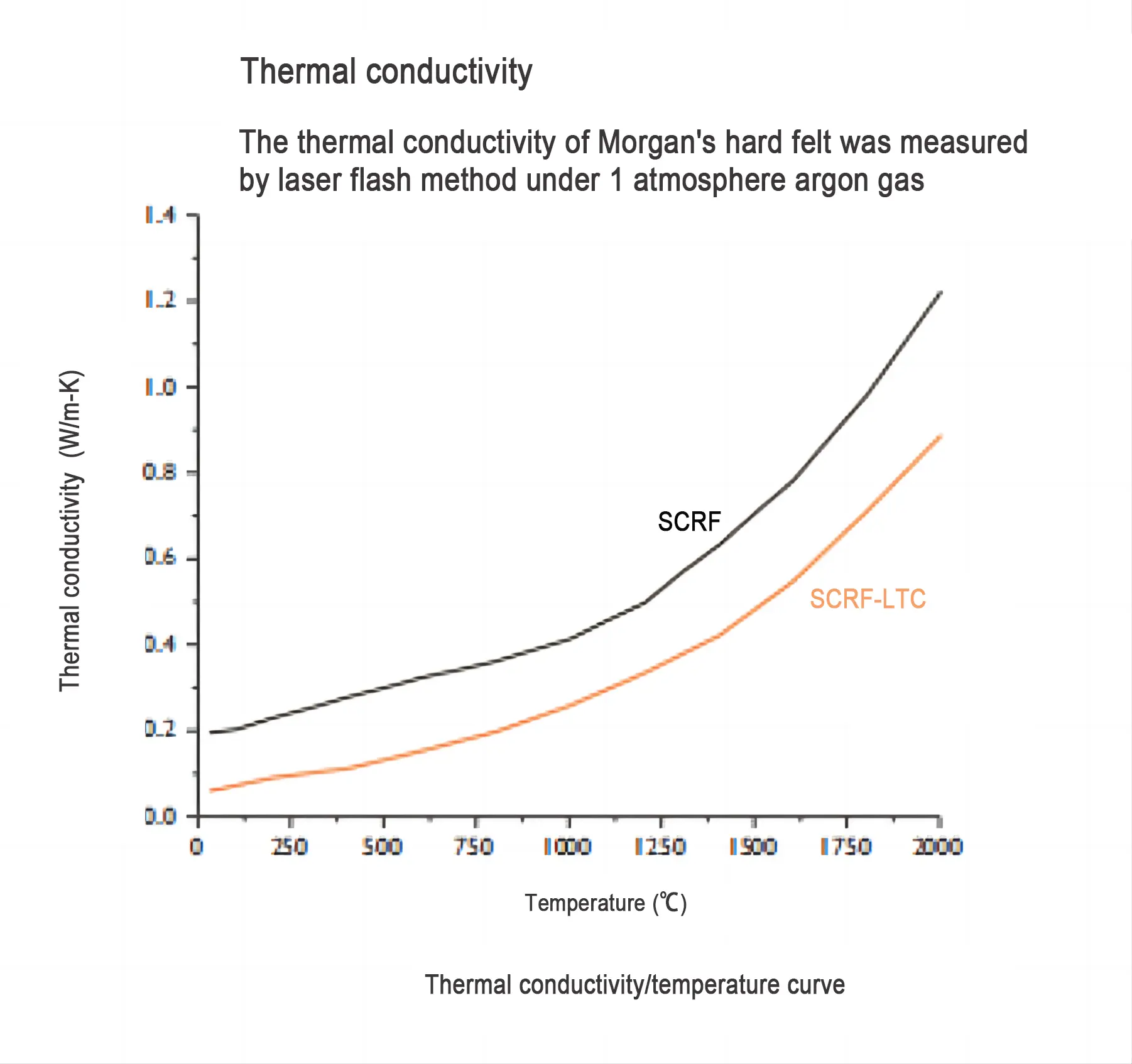

열 전도도 (w/mk) : 0.15-0.25 (25) 0.40-0.45 (1400)

특정 저항 (OHM.CM) : 0.18-0.22

Carbon Content (%): ≥99

Ash Content (%): ≤0.6

Moisture Absorption (%): ≤1.6

정제 척도 : Hight 순도

처리 온도 : 1450-2000

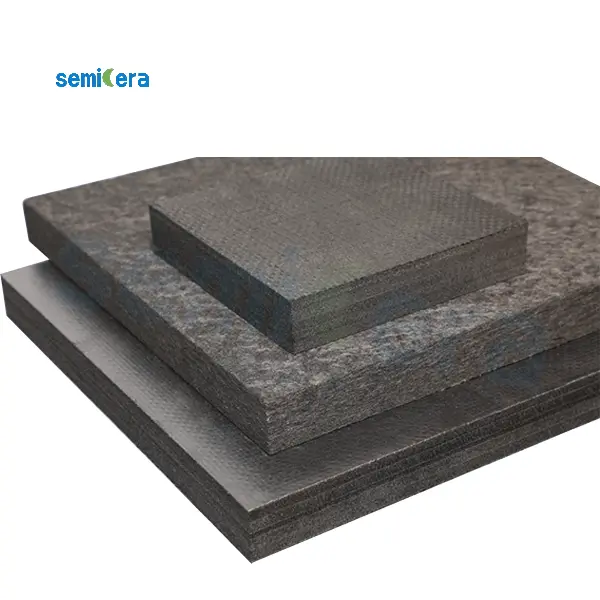

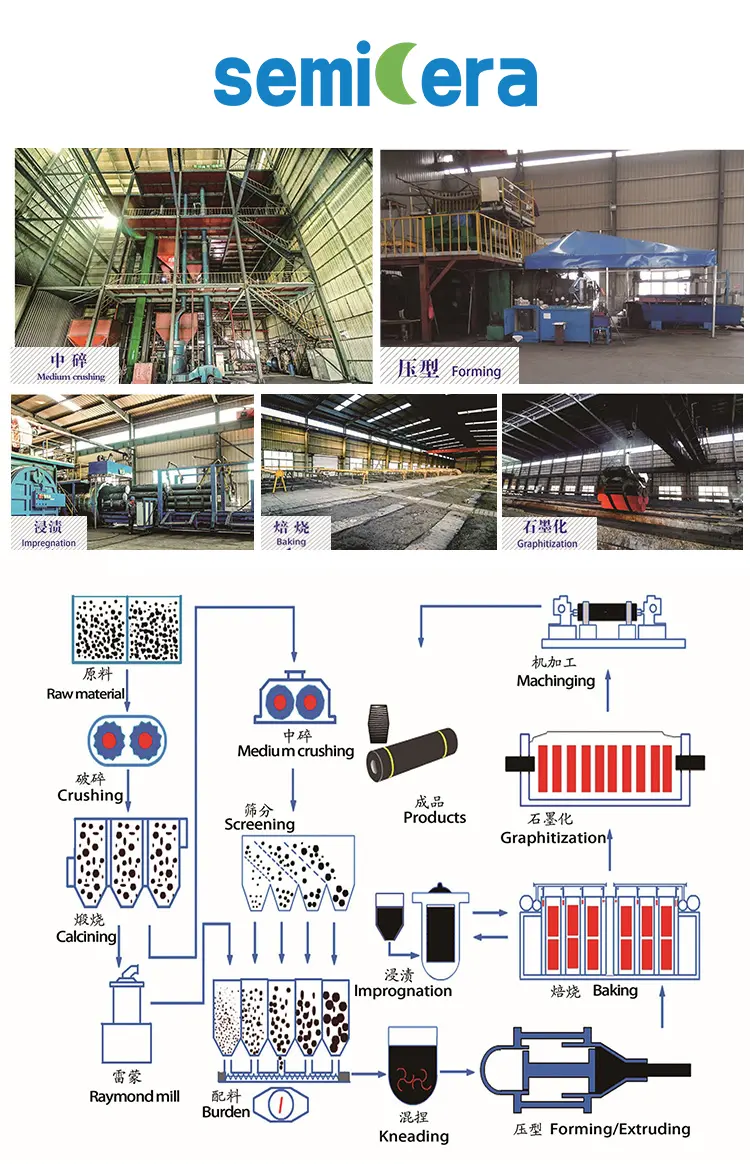

현재 원시 또는 가공 제품을 제공하는 데 사용할 수있는 4 개의 등급이 있습니다.:

SCRF: Purified cured graphite fiber hard felt, heat treatment temperature above 1900℃

SCRF-P : 고도로 정제 된 RGB 하드 펠트

SCRF-LTC: Purified solidified graphite fiber hard felt, heat treatment temperature above 1900℃, with better thermal insulation performance

SCRF-LTC-P : 고도로 정제 된 RGB-LTC 하드 펠트

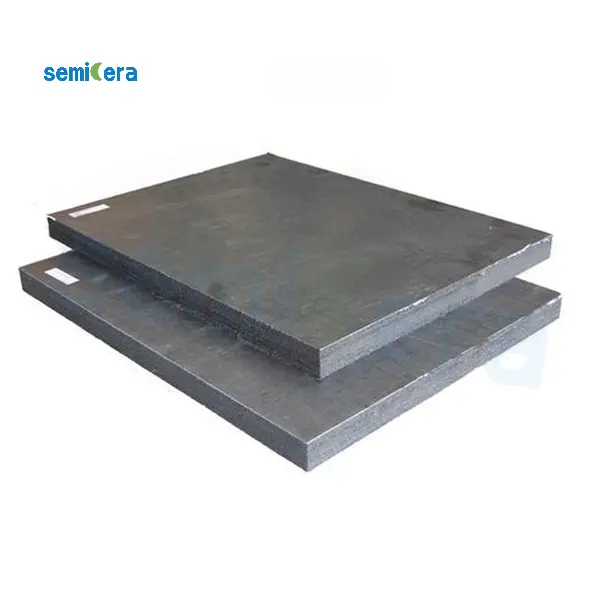

사용 가능한 크기:

플레이트 : 1500*1800 (최대) 두께 20-200mm

둥근 드럼 : 1500*2000 (Max) Deicknes 20-150mm

사각형 드럼 : 1500*1500*2000 (최대) 두께 60-120mm

적용 온도 범위 : 1250-2600

응용 분야:

•Vacuum furnaces

•Inert gas furnaces

•Heat treatment (경화, 탄화, 브레이징 등)

•Carbon fiber production

•Hard metal production

•Sintering applications

•Technical ceramic production

•CVD/PVD coasting