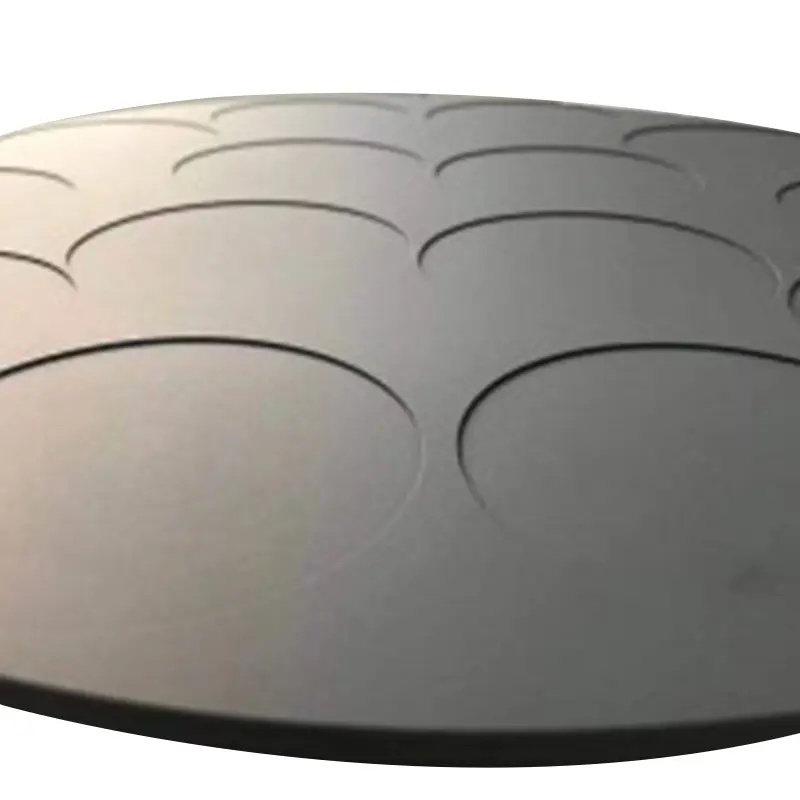

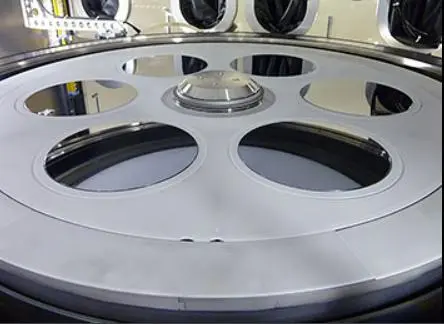

Semicera offers a comprehensive range of susceptors and graphite components designed for various epitaxy reactors.

Through strategic partnerships with industry-leading OEMs, extensive materials expertise, and advanced manufacturing capabilities, Semicera delivers tailored designs to meet the specific requirements of your application. Our commitment to excellence ensures that you receive optimal solutions for your epitaxy reactor needs.

CVD-SiC coating has the characteristics of uniform structure, compact material, high temperature resistance, oxidation resistance, high purity, acid&alkali resistance and organic reagent, with stable physical and chemical properties.

Compared with high-purity graphite materials, graphite begins to oxidize at 400C, which will cause a loss of powder due to oxidation, resulting in environmental pollution to peripheral devices and vacuum chambers, and increase impurities of high-purity environment.

However, SiC coating can maintain physical and chemical stability at 1600 degrees, It is widely used in modern industry, especially in semiconductor industry.

Our company provides SiC coating process services by CVD method on the surface of graphite, ceramics and other materials, so that special gases containing carbon and silicon react at high temperature to obtain high purity SiC molecules, molecules deposited on the surface of the coated materials, forming SIC protective layer. The SIC formed is firmly bonded to the graphite base, giving the graphite base special properties, thus making the surface of the graphite compact, Porosity-free, high temperature resistance, corrosion resistance and oxidation resistance.

1. 고 순도 SIC 코팅 흑연

2. 우수한 내열 및 열 균일 성

3. Fine SiC crystal coated for a smooth surface

4. 화학적 세정에 대한 내구성이 높다

| SIC-CVD | ||

| 밀도 | (G/CC) | 3.21 |

| 굽힘 강도 | (MPA) | 470 |

| 열 팽창 | (10-6/K) | 4 |

| 열전도율 | (w/mk) | 300 |

공급 능력:

한 달에 10000 조각/조각

포장 및 배송:

포장 : 표준 및 강력한 포장

폴리 백 + 상자 + 카톤 + 팔레트

포트:

Ningbo/Shenzhen/Shanghai

리드 타임:

| 수량 (조각) | 1 – 1000 | >1000 |

| est. 시간 (일) | 15 | To be negotiated |