Semicera Energy Technology Co., Ltd.는 웨이퍼 및 고급 반도체 소모품을 전문으로하는 선도적 인 공급 업체이며, 우리는 고품질의 신뢰할 수 있고 신뢰할 수 있고 혁신적인 제품을 반도체 제조, 광전지 산업 및 기타 관련 분야에 제공하기 위해 최선을 다하고 있습니다. 산화 알루미늄 등. 신뢰할 수있는 공급 업체로서, 우리는 제조 공정에서 소모품의 중요성을 이해하며, 고객의 요구를 충족시키기 위해 최고 품질 표준을 충족하는 제품을 제공하기 위해 노력하고 있습니다.

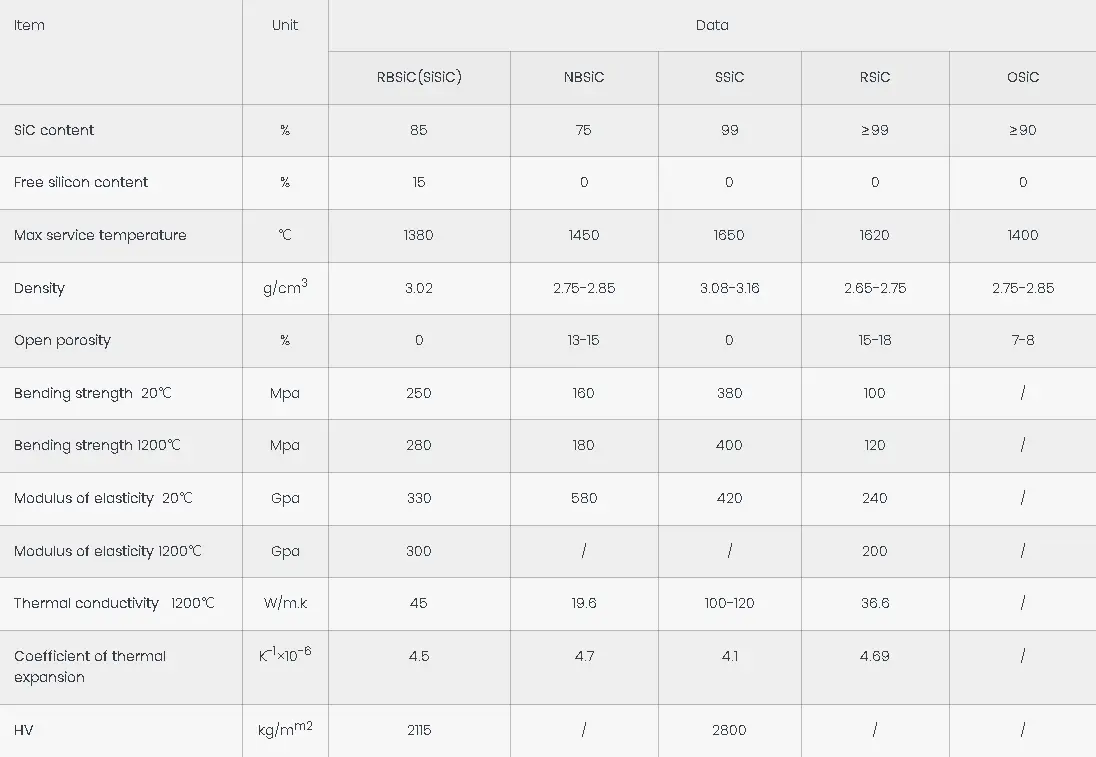

실리콘 카바이드는 높은 비용 성능과 우수한 재료 특성을 가진 새로운 유형의 세라믹입니다. 고강도 및 경도, 고온 저항, 열전 전도도 및 화학적 차단 저항과 같은 기능으로 인해 실리콘 카바이드는 거의 모든 화학 매체를 견딜 수 있습니다. 따라서 SIC는 석유 채굴, 화학, 기계 및 공역에 널리 사용되며, 원자력 에너지조차도 SIC에 대한 특별한 요구가 있습니다. 우리가 제공 할 수있는 일부 일반적인 응용 프로그램은 펌프, 밸브 및 보호 갑옷 등을위한 씰 링입니다.

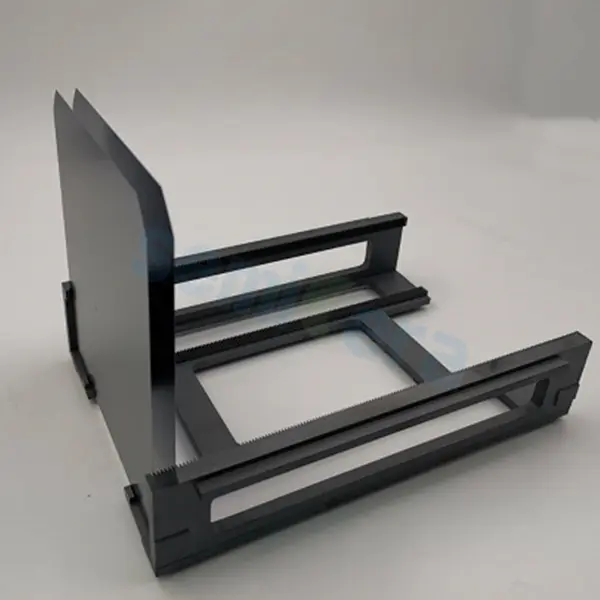

We are able to design and manufacture according to your specific dimensions with good quality and reasonable deliver time.

Advantages:

High temperature oxidation resistance

Excellent Corrosion resistance

Good Abrasion resistance

High coefficient of heat conductivity

Self-lubricity, low density

High hardness

Customized design.

Applications:

-Wear-resistant Field: bushing, plate, sandblasting nozzle,cyclone lining, grinding barrel,etc…

-High Temperature Field: siC Slab, Quenching Furnace Tube,Radiant Tube,crucible,Heating Element, Roller, Beam, Heat Exchanger, Cold Air Pipe, Burner Nozzle, Thermocouple Protection Tube, SiC boat,Kiln car Structure,Setter,etc.

-Military Bulletproof Field

-Silicon Carbide Semiconductor: SiC wafer boat, sic chuck,sic paddle, sic cassette, sic diffusion tube, wafer fork, suction plate, guideway,etc.

-Silicon Carbide Seal Field: all kinds of sealing ring, bearing, bushing, etc.

-Photovoltaic Field: Cantilever Paddle, Grinding Barrel, Silicon Carbide Roller,etc.

-Lithium Battery Field

|

材料Material |

R-SiC |

|

使用温度Working temperature (°C) |

1600°C ( 氧化气氛Oxidizing environment) 1700°C ( 还原气氛Reducing environment) |

|

sic含量SiC content (%) |

> 99 |

|

自由시 含量Free Si content (%) |

< 0.1 |

|

体积密度Bulk density (g/cm3) |

2.60-2.70 |

|

气孔率Apparent porosity (%) |

< 16 |

|

抗压强度Crushing strength (MPa) |

> 600 |

|

常温抗弯强度Cold bending strength (MPa) |

80-90 (20°C) |

|

高温抗弯强度Hot bending strength (MPa) |

90-100 (1400°C) |

|

热膨胀系数 Thermal expansion coefficient @1500°C (10-6/°C) |

4.70 |

|

导热系数Thermal conductivity @1200°C (W/m•K) |

23 |

|

杨氏模量Elastic modulus (GPa) |

240 |

|

抗热震性Thermal shock resistance |

很好Extremely good |