Semicera High Purity Silicon Carbide Paddle is designed for advanced semiconductor applications, providing superior thermal stability and mechanical strength. This SiC Paddle ensures precise wafer handling, making it an ideal choice for high-temperature environments. Contact us for inquiries!

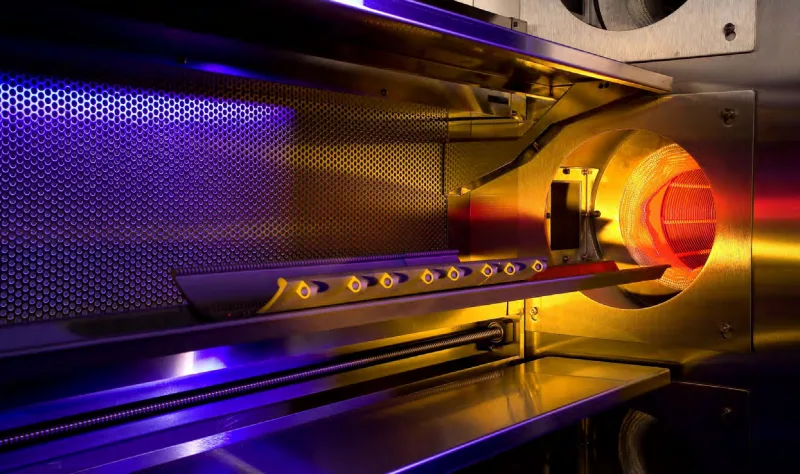

Semicera High Purity Silicon Carbide Paddle is meticulously engineered to meet the stringent demands of modern semiconductor manufacturing processes. This SiC Cantilever Paddle excels in high-temperature environments, offering unparalleled thermal stability and mechanical durability. The SiC Cantilever structure is built to withstand extreme conditions, ensuring reliable wafer handling throughout various processes.

One of the key innovations of the SiC Paddle is its lightweight yet robust design, which allows for easy integration into existing systems. Its high thermal conductivity helps maintain wafer stability during critical phases such as etching and deposition, minimizing the risk of wafer damage and ensuring higher production yields. The use of high-density silicon carbide in the paddle construction enhances its resistance to wear and tear, providing extended operational life and reducing the need for frequent replacements.

Semicera places a strong emphasis on innovation, delivering a SiC Cantilever Paddle that not only meets but exceeds industry standards. This paddle is optimized for use in various semiconductor applications, from deposition to etching, where precision and reliability are crucial. By integrating this cutting-edge technology, manufacturers can expect improved efficiency, reduced maintenance costs, and consistent product quality.

|

Fizyczne właściwości rekrystalizowanego węgliku krzemu |

|

|

Nieruchomość |

Typowa wartość |

|

Working temperature (°C) |

1600°C (with oxygen), 1700°C (reducing environment) |

|

Treść sic |

> 99.96% |

|

Darmowa zawartość SI |

<0,1% |

|

Gęstość luzem |

2.60-2.70 g/cm3 |

|

Pozorna porowatość |

<16% |

|

Compression strength |

> 600 MPa |

|

Zimna siła zginania |

80-90 MPa (20°C) |

|

Gorąca siła zginania |

90-100 MPa (1400°C) |

|

Thermal expansion @1500°C |

4.70 10-6/°C |

|

Thermal conductivity @1200°C |

23 W/m•K |

|

Moduł sprężystości |

240 GPA |

|

Odporność na wstrząsy termiczne |

Niezwykle dobry |