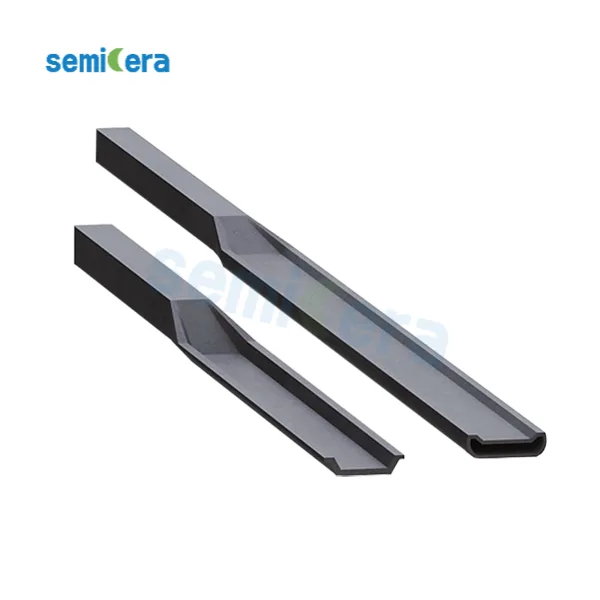

Silicon carbide paddle, also known as silicon carbide cantilever paddle, silicon carbide cantilever beam is a kind of silicon carbide ceramic products after 1850℃high temperature sintering, but high temperature sintering silicon carbide ceramic is a special ceramic products, by fine particlesα-SiC and additives pressed into a blank, in contact with liquid silicon at high temperature, carbon in the blank and infiltration of Si reaction, the formation ofβ-SiC,And combined with α-SiC, free silicon filled the porosity, so as to obtain high density ceramic materials; It has various superior properties of industrial ceramics.

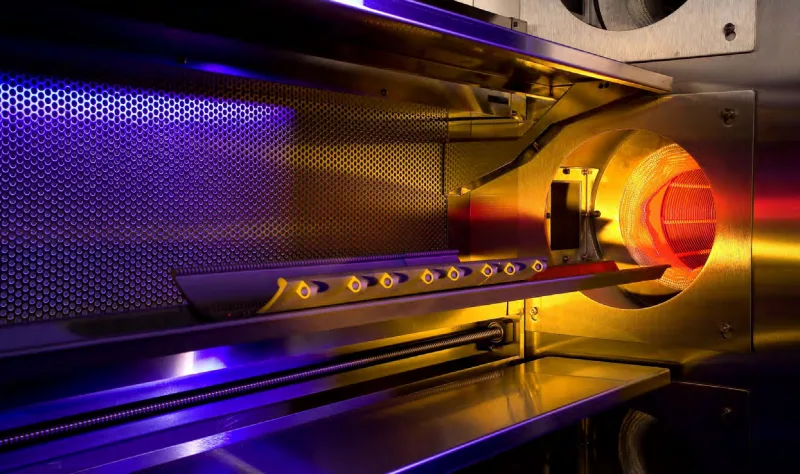

SiC Cantilever paddle is being used in the diffusion coating furnace of the photovoltaic industry for coating monocrystalline and polycrystalline silicon wafers. Its characteristic enables it to withstand high temperature and corrosion, giving it a long life span.

The SiC Cantilever paddle delivers SiC boats /quartz boats which carry silicon wafers into the high temperature diffusion coating furnace tube.

The length of our SiC Cantilever paddle ranges from 1,500 to 3,500 mm. SiC Cantilever paddle’s dimension can be tailor made according to customer’s specification.

|

Fizyczne właściwości rekrystalizowanego węgliku krzemu |

|

|

Nieruchomość |

Typowa wartość |

|

Working temperature (°C) |

1600°C (with oxygen), 1700°C (reducing environment) |

|

Treść sic |

> 99.96% |

|

Darmowa zawartość SI |

<0,1% |

|

Gęstość luzem |

2.60-2.70 g/cm3 |

|

Pozorna porowatość |

<16% |

|

Compression strength |

> 600 MPa |

|

Zimna siła zginania |

80-90 MPa (20°C) |

|

Gorąca siła zginania |

90-100 MPa (1400°C) |

|

Thermal expansion @1500°C |

4.70 10-6/°C |

|

Thermal conductivity @1200°C |

23 W/m•K |

|

Moduł sprężystości |

240 GPA |

|

Odporność na wstrząsy termiczne |

Niezwykle dobry |