Semicera Semiconductor Technology Co., Ltd. is a leading supplier specializing in wafer and advanced semiconductor consumables.We are dedicated to providing high-quality, reliable, and innovative products to semiconductor manufacturing,photovoltaic industryand other related fields.Our product line includes SiC/TaC coated graphite products and ceramic products, encompassing various materials such as silicon carbide, silicon nitride, and aluminum oxide and etc.As a trusted supplier, we understand the importance of consumables in the manufacturing process, and we are committed to delivering products that meet the highest quality standards to fulfill our customers’ needs.

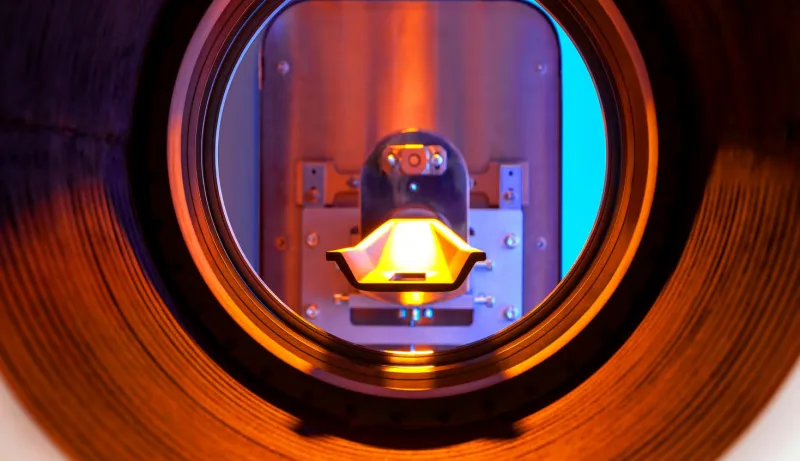

Semicera presents high-quality custom silicon carbide cantilever paddles crafted to elevate semiconductor manufacturing processes. The innovative SiC paddle design ensures exceptional durability and high thermal resistance, making it an essential component for wafer handling in challenging high-temperature environments.

The Silicon carbide paddle is built to withstand extreme thermal cycles while maintaining structural integrity, ensuring reliable wafer transportation during critical phases of semiconductor production. With superior mechanical strength, this wafer boat minimizes the risk of damage to wafers, leading to higher yields and consistent production quality.

One of the key innovations in Semicera’s SiC paddle lies in its custom design options. Tailored to meet specific production needs, the paddle offers flexibility in integration with various equipment setups, making it an ideal solution for modern fabrication processes. The lightweight yet robust construction enables easy handling and reduces operational downtime, contributing to improved efficiency in semiconductor production.

In addition to its thermal and mechanical properties, the Silicon carbide paddle offers excellent chemical resistance, allowing it to perform reliably even in harsh chemical environments. This makes it particularly suitable for use in processes involving etching, deposition, and high-temperature treatment, where maintaining the integrity of the wafer boat is crucial for ensuring high-quality outputs.

|

Fizyczne właściwości rekrystalizowanego węgliku krzemu |

|

|

Nieruchomość |

Typowa wartość |

|

Working temperature (°C) |

1600°C (with oxygen), 1700°C (reducing environment) |

|

Treść sic |

> 99.96% |

|

Darmowa zawartość SI |

<0,1% |

|

Gęstość luzem |

2.60-2.70 g/cm3 |

|

Pozorna porowatość |

<16% |

|

Compression strength |

> 600 MPa |

|

Zimna siła zginania |

80-90 MPa (20°C) |

|

Gorąca siła zginania |

90-100 MPa (1400°C) |

|

Thermal expansion @1500°C |

4.70 10-6/°C |

|

Thermal conductivity @1200°C |

23 W/m•K |

|

Moduł sprężystości |

240 GPA |

|

Odporność na wstrząsy termiczne |

Niezwykle dobry |