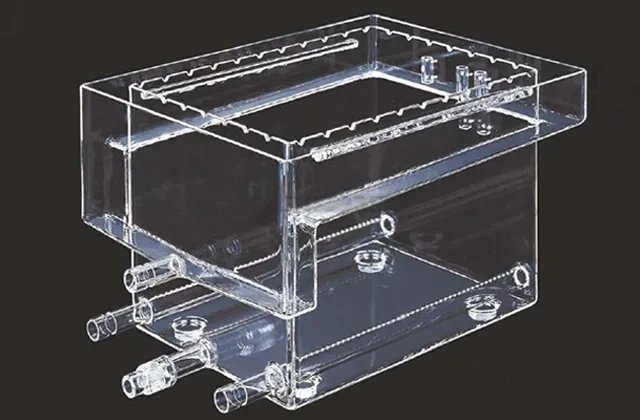

Semicera’s quartz cleaning tanks are designed for optimal performance in semiconductor manufacturing. This high-purity quartz tank ensures efficient and thorough wafer cleaning, significantly improving cleanliness and yield. Our quartz cleaning tanks withstand corrosive chemicals and high temperatures, making them a reliable choice for your wafer wet processing needs. We look forward to being your long-term partner in China.

The Quartz Cleaning Tank from Semicera is an essential tool for achieving optimal cleanliness in semiconductor manufacturing. Designed specifically for wafer wet processing, this tank ensures effective wafer cleaning through advanced techniques that minimize contamination and enhance yield. Utilizing state-of-the-art materials, the Semicera tank is engineered for superior performance in various wafer cleaning methods.

Crafted from high-purity quartz, the Quartz Cleaning Tank offers excellent resistance to aggressive chemicals and high temperatures. This durability is critical in the semiconductor cleaning process, where both wet chemical etching processes and dry etch wet etch methods are employed. With its robust design, the tank is suitable for various applications, including wet etching and serving as an efficient quartz bath for comprehensive cleaning routines.

By integrating the Quartz Cleaning Tank into your production line, you can streamline wafer cleaning processes, ensuring that each wafer is thoroughly cleaned and ready for subsequent fabrication steps. This reliable tank aids in reducing particle contamination and supports higher efficiency during wet etching operations, ultimately leading to improved product quality.

Dzięki zbiornikowi czyszczącemu kwarcowi Semicera zyskujesz pewność wysokiej wydajności i długowieczności. Jego zdolność do wytrzymania rygorów przetwarzania mokrego wafla sprawia, że jest to cenny zasób w dowolnym obiekcie półprzewodników, zapewniając spokój ducha poprzez zwiększoną trwałość i niezawodność w wymagających środowiskach. Wybierz półcesta dla swoich rozwiązań czyszczących i doświadcz niezrównanej jakości w procesach produkcyjnych półprzewodników.

We can handle various shapes according to your needs, ranging from large single and double quartz baths to small quartz crucibles. In addition to quartz materials, we can also process containers made of hard glass.

·Used for wafer wet cleaning processes.

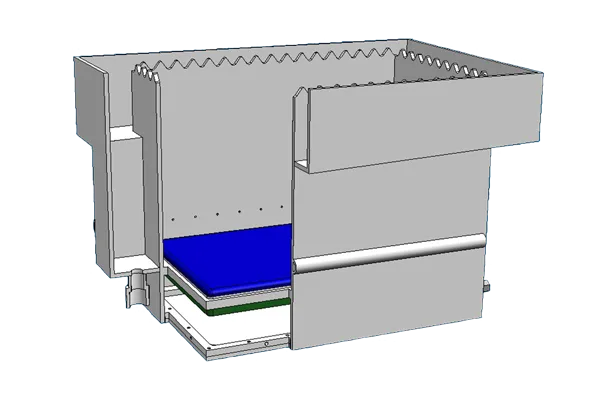

·Single slot/double slot (overflow slot).

·Can manufacture up to 12 inches.