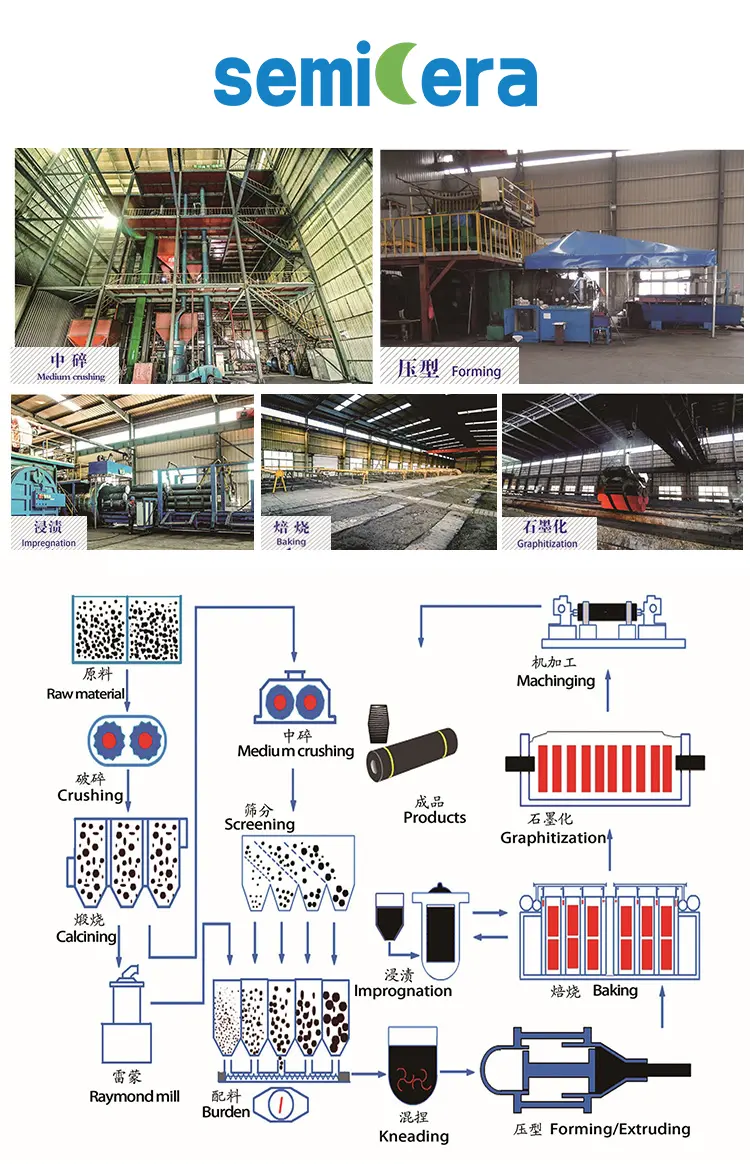

Semicera Semiconductor. is a leading supplier specializing in wafers and advanced semiconductor consumables. We are dedicated to providing high-quality, reliable, and innovative products to semiconductor manufacturing, photovoltaic industry and other related fields.Our product line includes SiC/TaC coated graphite products and ceramic products, encompassing various materials such as silicon carbide, silicon nitride, and aluminum oxide and etc.As a trusted supplier, we understand the importance of consumables in the manufacturing process, and we are committed to delivering products that meet the highest quality standards to fulfill our customers’ needs.

|

اسم المنتج |

شعر الجرافيت |

|

التكوين الكيميائي |

ألياف الكربون |

|

كثافة كبيرة |

0.12-0.14g/cm3 |

|

محتوى الكربون |

> = 99% |

|

قوة الشد |

0.14Mpa |

|

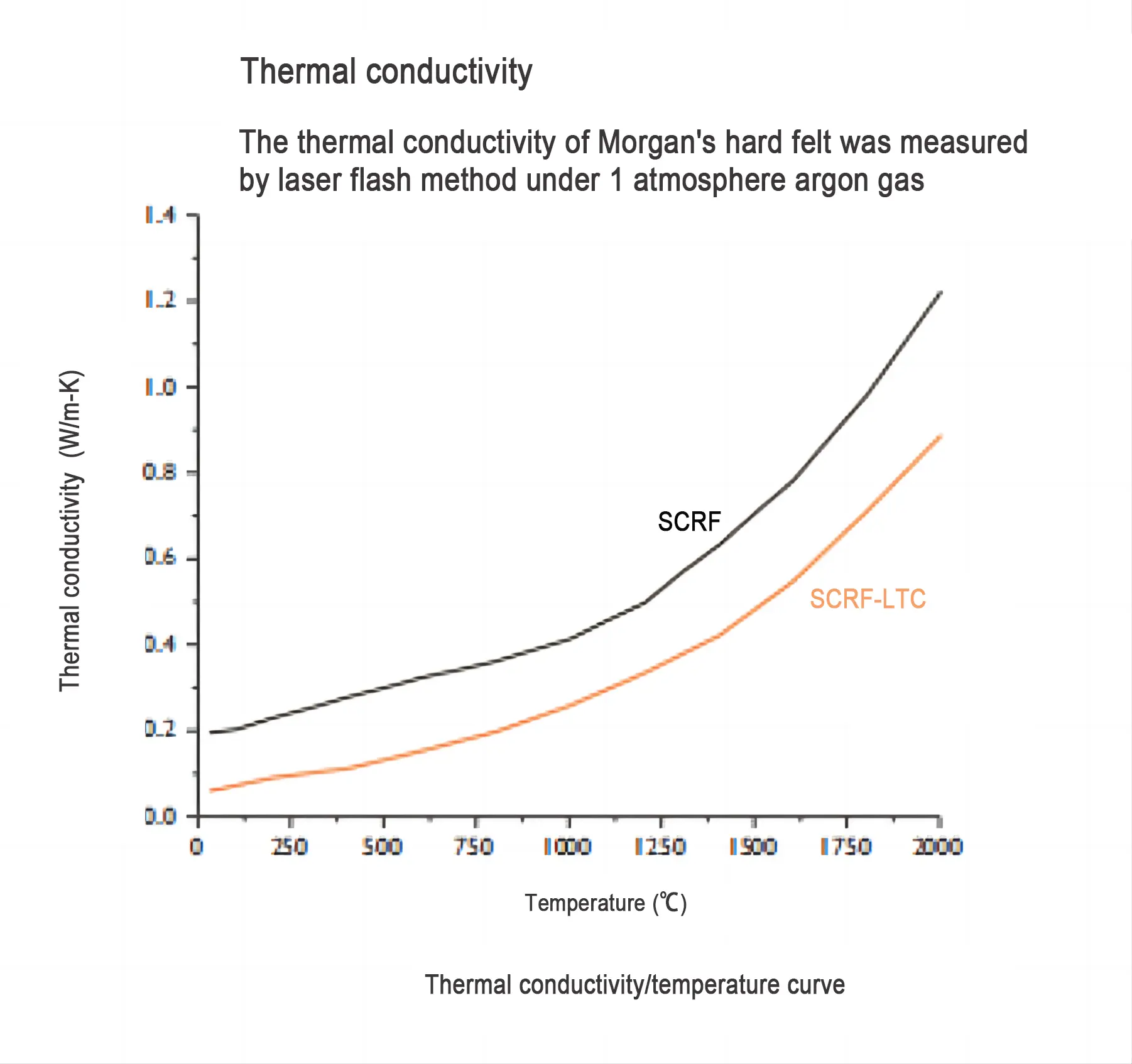

Thermal conductivity(1150℃) |

0.08 ~ 0.14W/MK |

|

رماد |

<= 0.005% |

|

الإجهاد الساحق |

8-10N/cm |

|

سماكة |

1-10mm |

|

درجة حرارة المعالجة |

2500(℃) |

Volume Density (g/cm3): 0.22-0.28

Tensile Strength (Mpa): 2.5 (Deformation 5%)

Thermal Conductivity (W/m.k): 0.15-0.25(25) 0.40-0.45(1400)

Specific Resistance (Ohm.cm): 0.18-0.22

Carbon Content (%): ≥99

Ash Content (%): ≤0.6

Moisture Absorption (%): ≤1.6

Purification Scale : Hight Purity

Processing Temperature : 1450-2000

تتوفر حاليًا أربع درجات لتوفير منتجات خام أو معالجة:

SCRF: Purified cured graphite fiber hard felt, heat treatment temperature above 1900℃

SCRF-P: Highly purified RGB hard felt

SCRF-LTC: Purified solidified graphite fiber hard felt, heat treatment temperature above 1900℃, with better thermal insulation performance

SCRF-LTC-P: Highly purified RGB-LTC hard felt

الحجم المتاح:

اللوحة: 1500*1800 (كحد أقصى) سمك 20-200 مم

أسطوانة مستديرة: 1500*2000 (الحد الأقصى) Thicknes 20-150mm

طبلة مربعة: 1500*1500*2000 (الحد الأقصى) سماكة 60-120 ملم

نطاق درجة الحرارة التطبيقي: 1250-2600

Fields of applications:

•Vacuum furnaces

•Inert gas furnaces

•Heat treatment (hardening, carbonization, brazing, etc.)

•Carbon fiber production

•Hard metal production

•Sintering applications

•Technical ceramic production

•CVD/PVD coasting