Semicera is a high-tech enterprise engaged in material research for many years, with a leading R&D team and integrated R&D and manufacturing. Provide customized Silicon Carbide Coated Epitaxial Reactor Barrelto discuss with our technical experts how to get the best performance and market advantage for your products.

لماذا طلاء كربيد السيليكون؟

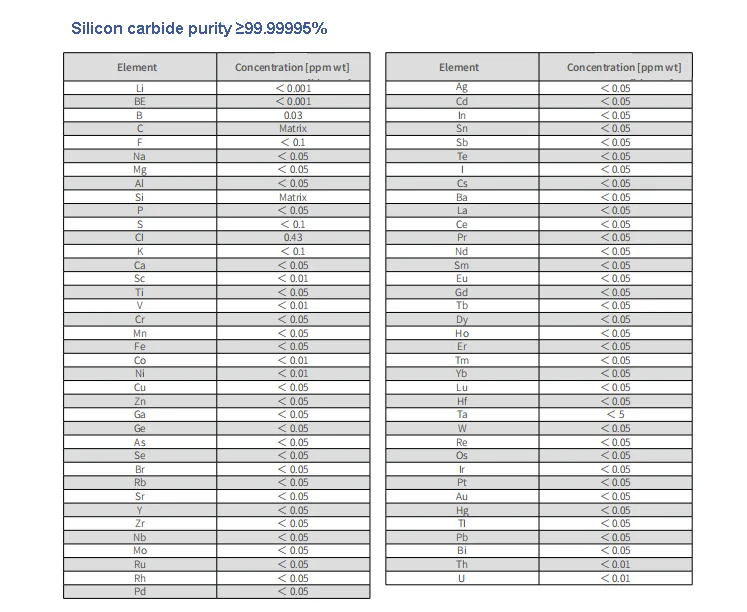

In the semiconductor field, the stability of each component is very important for the whole process. However, in a high-temperature environment, graphite is easily oxidized and lost, and SiC coating can provide stable protection for graphite parts. In the شبه team, we have our own graphite purification processing equipment, which can control the purity of graphite below 5ppm. The purity of the silicon carbide coating is below 0.5 ppm.

ميزتنا ، لماذا تختار semicera؟

✓Top-quality in China market

✓Good service always for you, 7*24 hours

✓Short date of delivery

✓Small MOQ welcome and accepted

✓Custom services

طلب

حساء النمو epitaxy

تحتاج رقائق كربيد السيليكون/السيليكون إلى المرور من خلال عمليات متعددة لاستخدامها في الأجهزة الإلكترونية. عملية مهمة هي السيليكون/كذا epitaxy ، حيث يتم تنفيذ رقائق السيليكون/كذا على قاعدة الجرافيت. تشمل المزايا الخاصة لقاعدة الجرافيت المغلفة بالكربيد في سيليكون من Semicera نقاءًا مرتفعًا للغاية ، وطلاء موحد ، وعمر خدمة طويل للغاية. لديهم أيضا مقاومة كيميائية عالية والاستقرار الحراري.

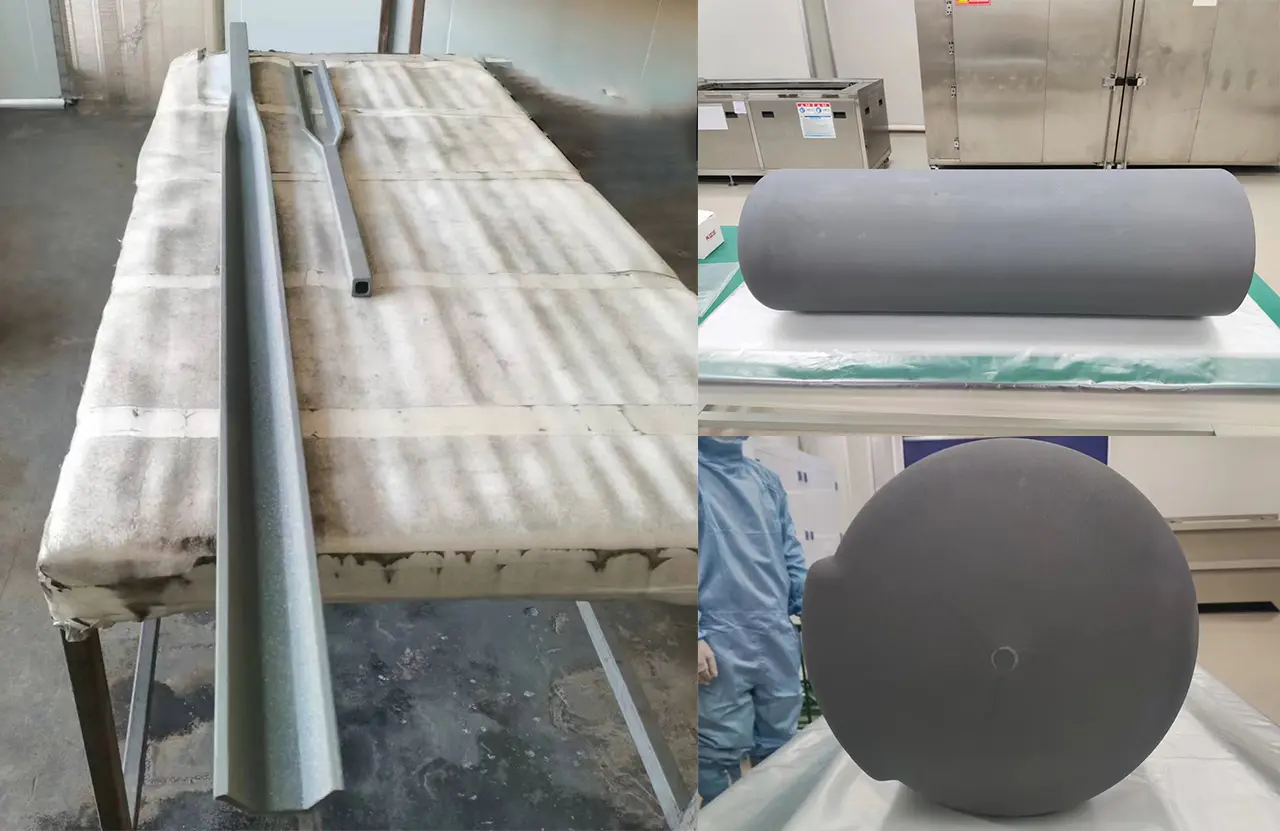

LED إنتاج رقاقة

أثناء الطلاء الواسع لمفاعل MOCVD ، تنقل قاعدة الكواكب أو الناقل رقاقة الركيزة. إن أداء المادة الأساسية له تأثير كبير على جودة الطلاء ، مما يؤثر بدوره على معدل خردة الشريحة. تزيد القاعدة المغلفة بالسيليكون المغطاة بالكربيد في Semicera من كفاءة تصنيع رقائق LED عالية الجودة وتقلل من انحراف الطول الموجي. نحن أيضًا نوفر مكونات جرافيت إضافية لجميع مفاعلات MOCVD المستخدمة حاليًا. يمكننا أن نغطى أي مكون تقريبًا مع طلاء كربيد السيليكون ، حتى لو كان قطر المكون يصل إلى 1.5 متر ، فلا يزال بإمكاننا التغلب على كربيد السيليكون.

مجال أشباه الموصلات ، عملية نشر الأكسدة، إلخ.

في عملية أشباه الموصلات ، تتطلب عملية توسيع الأكسدة نقاءًا عاليًا للمنتج ، وفي Semicera نقدم خدمات طلاء مخصصة و CVD لغالبية أجزاء كربيد السيليكون.

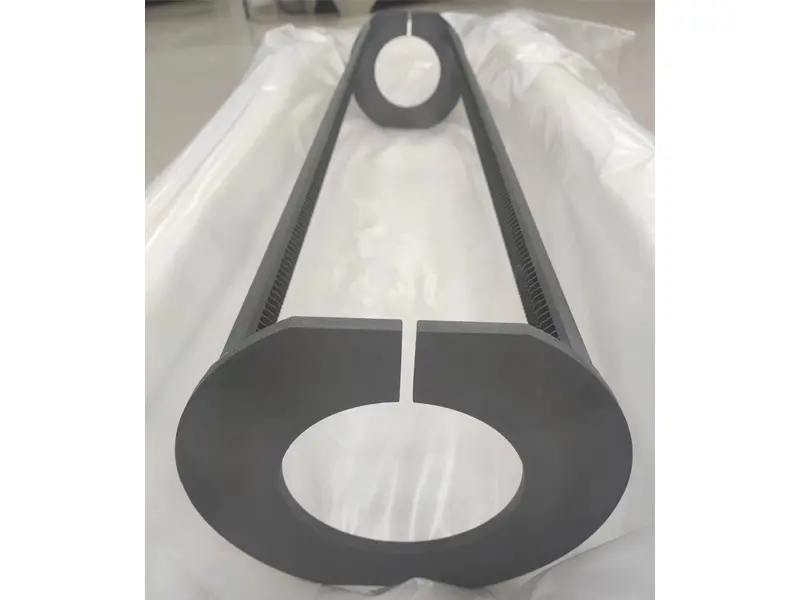

تُظهر الصورة التالية ملاط كربيد السيليكون الذي تم تجهيزه من Semicea وأنبوب فرن كربيد السيليكون الذي يتم تنظيفه في 100 0-مستوى خالية من الغبار غرفة. عمالنا يعملون قبل الطلاء. يمكن أن تصل نقاء كربيد السيليكون لدينا إلى 99.99% ، ونقاء طلاء SIC أكبر من 99.99995% .

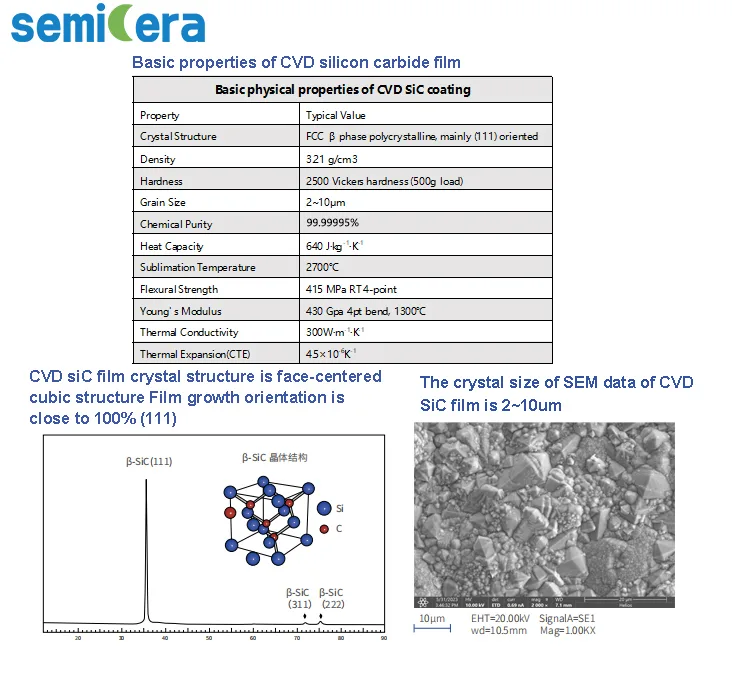

بيانات SEMI-CERA 'CVD SIC Performace.