The Tantalum Carbide Coating Graphite Plate by Semicera is engineered for high-performance applications in silicon carbide epitaxy and crystal growth. This plate offers exceptional stability in high-temperature, corrosive, and high-pressure environments. Ideal for use in advanced reactors and furnace structures, it enhances system performance and longevity. Semicera ensures superior quality and reliability with cutting-edge coating technology for demanding engineering needs.

Tantalum carbide coated graphite sheet is a graphite material with a thin layer of tantalum carbide on the surface of the substrate. The thin layer of tantalum carbide is usually formed on the surface of the graphite substrate by techniques such as physical vapor deposition (PVD) or chemical vapor deposition (CVD). This coating has excellent properties such as high hardness, excellent wear resistance, corrosion resistance and high temperature stability.

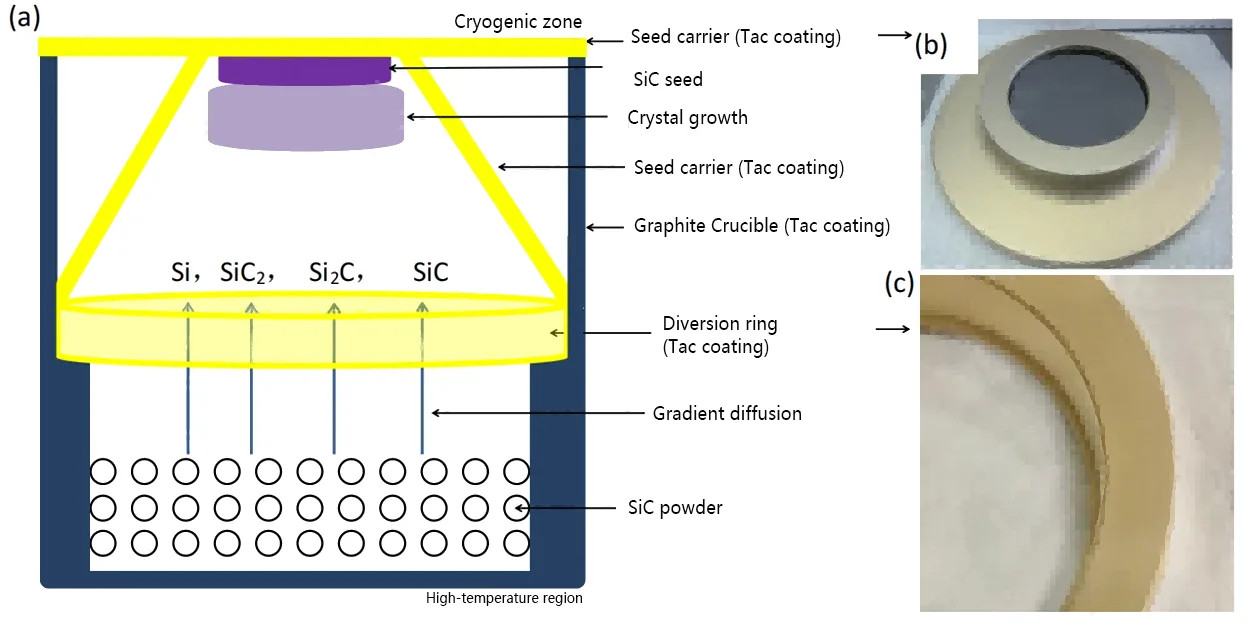

يوفر Semicera الطلاءات المتخصصة في Tantalum Carbide (TAC) لمختلف المكونات والناقلات. Semicera leading coating process enables tantalum carbide (TaC) coatings to achieve high purity, high temperature stability and high chemical tolerance, improving product quality of SIC/GAN crystals and EPI layers (Graphite coated TaC susceptor), and extending the life of key reactor components. The use of tantalum carbide TaC coating is to solve the edge problem and improve the quality of crystal growth, and Semicera has breakthrough solved the tantalum carbide coating technology (CVD), reaching the international advanced level.

After years of development, Semicera has conquered the technology of CVD TaC with the joint efforts of the R&D department. Defects are easy to occur in the growth process of SiC wafers, but after using TaC, the difference is significant. Below is a comparison of wafers with and without TaC, as well as Simicera’ parts for single crystal growth.

The main advantages of tantalum carbide coated graphite sheet include:

1. High temperature resistance: Tantalum carbide has a high melting point and excellent high temperature stability, making the coated graphite sheet suitable for use in high temperature environments.

2. Corrosion resistance: Tantalum carbide coating can resist the erosion of many chemical corrosive substances and extend the service life of the material.

3. High hardness: The high hardness of the tantalum carbide thin layer provides good wear resistance and is suitable for applications requiring high wear resistance.

4. Chemical stability: Tantalum carbide coating has excellent stability to chemical corrosion and is suitable for use in some corrosive media.

Moreover, Semicera’s TaC-coated products exhibit a longer service life and greater high-temperature resistance compared to SiC coatings. Laboratory measurements have demonstrated that our TaC coatings can consistently perform at temperatures up to 2300 degrees Celsius for extended periods. Below are some examples of our samples: