The Soft Graphite Felt by Semicera is a premium material renowned for its excellent thermal conductivity and lightweight properties. Engineered for versatility, this felt is ideal for various applications, including aerospace and electronics. With Semicera’s commitment to quality, our Soft Graphite Felt ensures exceptional performance and durability, making it a reliable choice for your industrial needs. Choose Semicera for innovative solutions that elevate your projects.

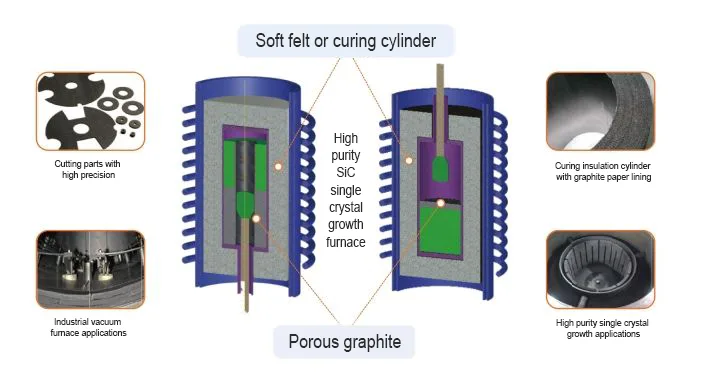

The Soft Graphite Felt from Semicera is a versatile and high-performance material designed for a range of industrial applications. This felt is made from high-quality isostatic graphite, offering exceptional thermal conductivity and resilience. Its porous structure enhances performance in various environments, making it ideal for use in C/C composites and other high-temperature applications.

With Semicera’s commitment to quality, our Soft Graphite Felt provides not only the flexibility of soft felt but also the durability needed for demanding applications. Whether used in combination with graphite foil or as a standalone material, it ensures reliable performance and longevity. Trust Semicera for innovative solutions that meet your industrial needs.

|

Produktname |

Graphit Filz |

|

Chemische Zusammensetzung |

Kohlefaser |

|

Schüttdichte |

0.12-0.14g/cm3 |

|

Kohlenstoffgehalt |

> = 99% |

|

Zugfestigkeit |

0.14Mpa |

|

Thermal conductivity(1150℃) |

0,08 ~ 0,14W/mk |

|

Asche |

<= 0,005% |

|

Stress zerkleinern |

8-10N/cm |

|

Dicke |

1-10mm |

|

Verarbeitungstemperatur |

2500(℃) |

Derzeit in vier Spezifikationen erhältlich, die jeweils in Rollen, Teilen und vorgerollten Filzrohre erhältlich sind:

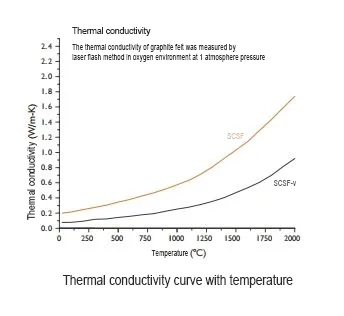

SCSF: High purity graphite felt, better thermal conductivity, heat treatment temperature of more than 1900℃

SCSF-P: Ultrahohe Reinheit SCSF-B Graphit Filz

SCSF-v: High purity graphite felt, heat treatment temperature of more than 2650℃, low thermal conductivity

SCSF-VP: Ultra-hohe Reinheit SCSF-D Graphit Filz

Eigenschaften :

-Hervorragende thermische Stabilität

-Hohe mechanische Stärke

-Gute elektrische und thermische Leitfähigkeit

-Ausgezeichnete Resistenz gegen thermischen Schock und Korrosion

-Hohe materielle Reinheit

-Hohe elektrische Belastungskapazität

-Einheitliches Temperaturprofil

Anwendungsfelder:

-Vakuumöfen

-Inerte Gasöfen

-Wärmebehandlung

(Härtung, Karbonisierung, Löschen usw.)

-Kohlefaserproduktion

-Harte Metallproduktion

-Sinteranwendungen

-Technische Keramikproduktion

-CVD/PVD -Rollen