Semicera Energy Technology Co., Ltd. is a leading supplier of advanced semiconductor ceramics and the only manufacturer in China that can simultaneously provide high-purity silicon carbide ceramic(especially the Recrystallized SiC) and CVD SiC coating. In addition, our company is also committed to ceramic fields such as alumina, aluminum nitride, zirconia, and silicon nitride, etc.

|

Produktname |

Graphit Filz |

|

Chemische Zusammensetzung |

Kohlefaser |

|

Schüttdichte |

0.12-0.14g/cm3 |

|

Kohlenstoffgehalt |

> = 99% |

|

Zugfestigkeit |

0.14Mpa |

|

Wärmeleitfähigkeit (1150 ℃) |

0,08 ~ 0,14W/mk |

|

Asche |

<= 0,005% |

|

Stress zerkleinern |

8-10N/cm |

|

Dicke |

1-10mm |

|

Verarbeitungstemperatur |

2500(℃) |

Volumendichte (G/cm3): 0,22-0,28

Zugfestigkeit (MPA): 2,5 (Deformation 5%)

Wärmeleitfähigkeit (W/mk): 0,15-0,25 (25) 0,40-0,45 (1400)

Spezifischer Widerstand (OHM.CM): 0.18-0.22

Carbon Content (%): ≥99

Ash Content (%): ≤0.6

Moisture Absorption (%): ≤1.6

Reinigungsskala: Hight Reinity

Verarbeitungstemperatur: 1450-2000

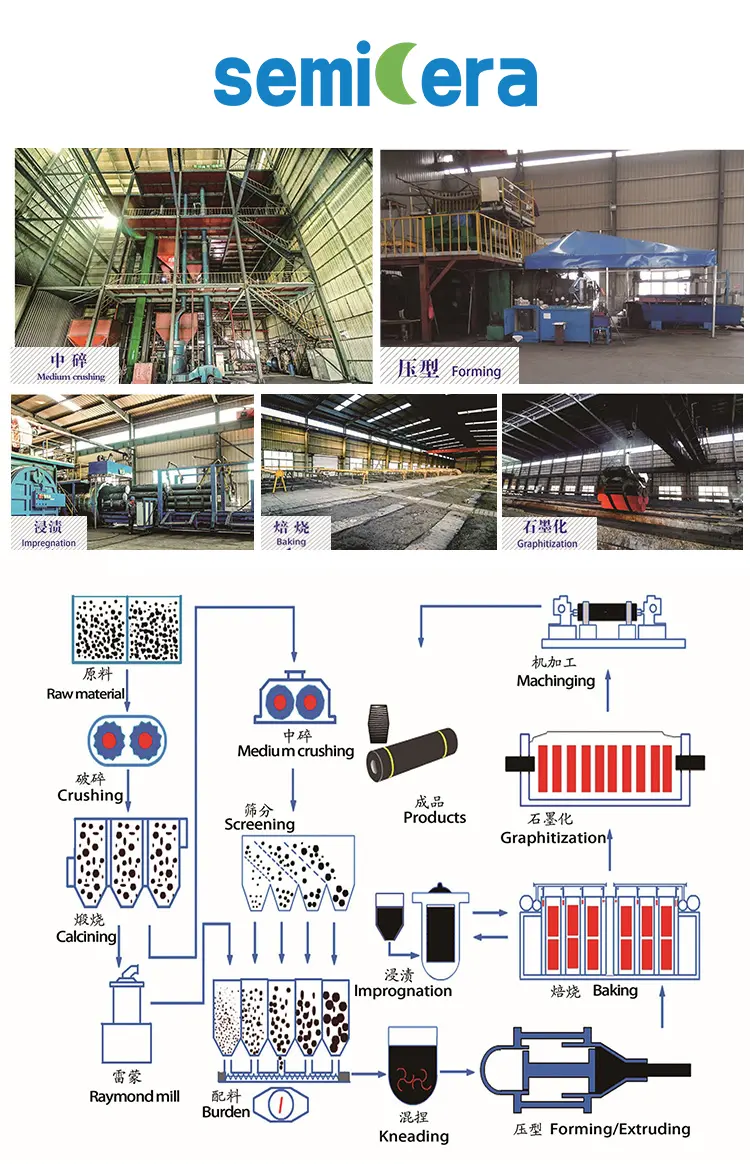

Derzeit stehen vier Klassen zur Verfügung, um rohe oder verarbeitete Produkte bereitzustellen:

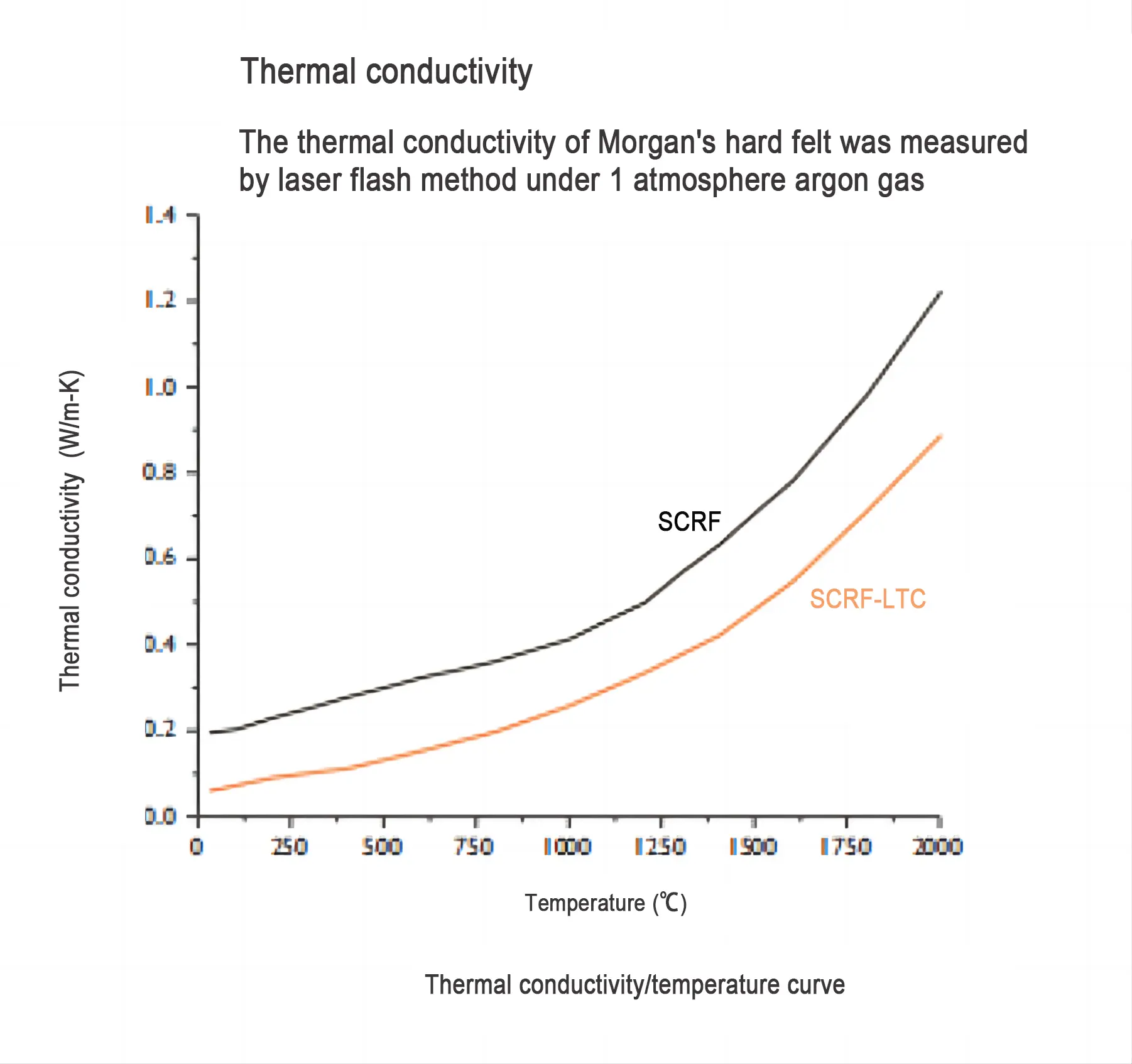

SCRF: Purified cured graphite fiber hard felt, heat treatment temperature above 1900℃

SCRF-P: Highly purified RGB hard felt

SCRF-LTC: Purified solidified graphite fiber hard felt, heat treatment temperature above 1900℃, with better thermal insulation performance

SCRF-LTC-P: Highly purified RGB-LTC hard felt

Verfügbare Größe:

Platte: 1500*1800 (max) Dicke 20-200 mm

Runde Trommel: 1500*2000 (max) Dickes 20-150 mm

Quadrattrommel: 1500*1500*2000 (max) Dicke 60-120 mm

Anwendungstemperaturbereich: 1250-2600

Anwendungsfelder:

•Vacuum furnaces

•Inert gas furnaces

•Heat treatment (Härtung, Karbonisierung, Löschen usw.)

•Carbon fiber production

•Hard metal production

•Sintering applications

•Technical ceramic production

•CVD/PVD coasting