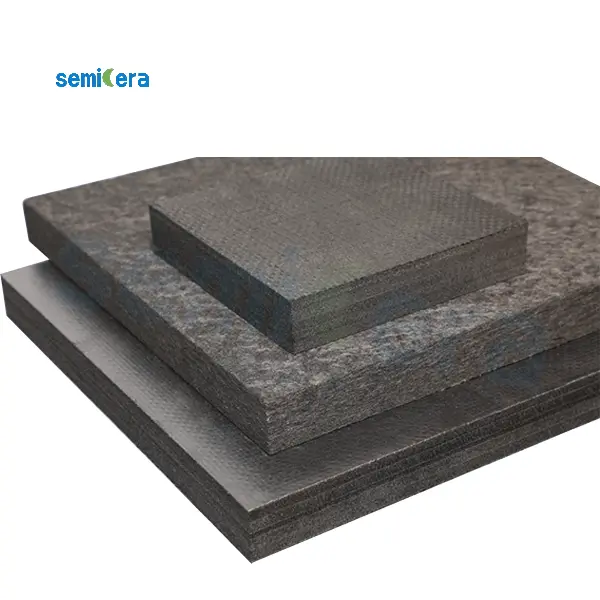

Semicera’s Graphite Rigid Felt for Vacuum Furnace is specifically engineered for high-performance use in vacuum furnace applications. Offering excellent thermal conductivity, chemical resistance, and structural stability, this high-quality graphite material ensures optimal heat management and durability. Ideal for industries such as metallurgy, semiconductor, and material processing, Semicera’s graphite rigid felt delivers reliable performance and efficiency under extreme conditions, making it the perfect solution for your vacuum furnace needs.

|

Produktname |

Graphit Filz |

|

Chemische Zusammensetzung |

Kohlefaser |

|

Schüttdichte |

0.12-0.14g/cm3 |

|

Kohlenstoffgehalt |

> = 99% |

|

Zugfestigkeit |

0.14Mpa |

|

Thermal conductivity(1150℃) |

0,08 ~ 0,14W/mk |

|

Asche |

<= 0,005% |

|

Stress zerkleinern |

8-10N/cm |

|

Dicke |

1-10mm |

|

Verarbeitungstemperatur |

2500(℃) |

Volumendichte (G/cm3): 0,22-0,28

Zugfestigkeit (MPA): 2,5 (Deformation 5%)

Wärmeleitfähigkeit (W/mk): 0,15-0,25 (25) 0,40-0,45 (1400)

Spezifischer Widerstand (OHM.CM): 0.18-0.22

Carbon Content (%): ≥99

Ash Content (%): ≤0.6

Moisture Absorption (%): ≤1.6

Reinigungsskala: Hight Reinity

Verarbeitungstemperatur: 1450-2000

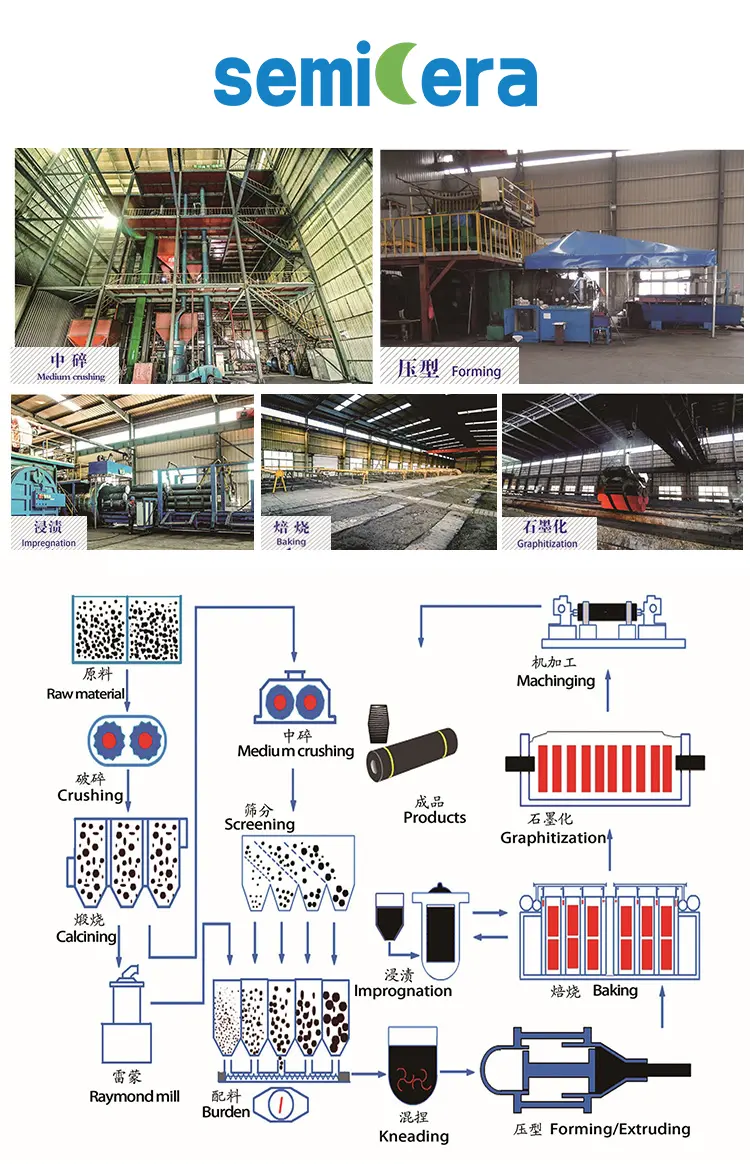

Derzeit stehen vier Klassen zur Verfügung, um rohe oder verarbeitete Produkte bereitzustellen:

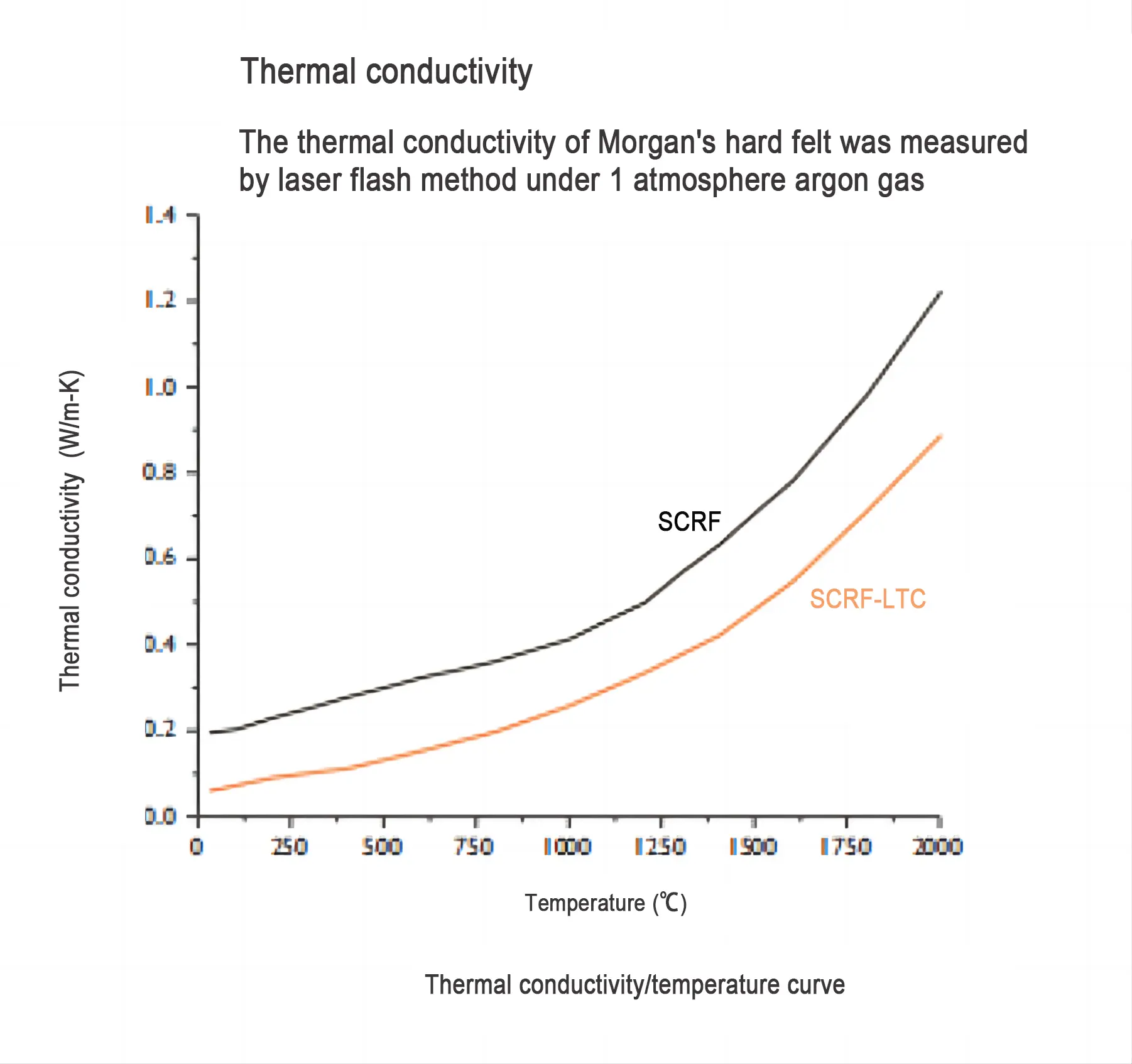

SCRF: Purified cured graphite fiber hard felt, heat treatment temperature above 1900℃

SCRF-P: Highly purified RGB hard felt

SCRF-LTC: Purified solidified graphite fiber hard felt, heat treatment temperature above 1900℃, with better thermal insulation performance

SCRF-LTC-P: Highly purified RGB-LTC hard felt

Verfügbare Größe:

Platte: 1500*1800 (max) Dicke 20-200 mm

Runde Trommel: 1500*2000 (max) Dickes 20-150 mm

Quadrattrommel: 1500*1500*2000 (max) Dicke 60-120 mm

Anwendungstemperaturbereich: 1250-2600

Anwendungsfelder:

•Vacuum furnaces

•Inert gas furnaces

•Heat treatment (Härtung, Karbonisierung, Löschen usw.)

•Carbon fiber production

•Hard metal production

•Sintering applications

•Technical ceramic production

•CVD/PVD coasting