![]()

Rivestimento SiC technology uses silicon carbide to create protective layers on various surfaces. You benefit from its exceptional hardness, thermal stability, and resistance to wear and corrosion. These properties make it indispensable in industries like aerospace, electronics, and energy. For example, silicon carbide coated susceptors improve performance in high-temperature environments, while sic coated susceptors enhance durability in semiconductor manufacturing. SIC Tac Coating also offers lightweight solutions for advanced applications. By adopting this technology, you can achieve superior efficiency, longevity, and cost savings across diverse industrial processes.

Asporto chiave

- SiC coating makes tools last longer and resist wearing out.

- These coatings handle heat over 1,000°C, great for hot uses.

- SiC coatings stop rust and chemical harm in tough places.

- They save money by cutting down on repairs and replacements.

- Being lightweight, SiC coatings help cars and planes use less fuel.

- They protect semiconductors from damage and help manage heat better.

- New methods like 3D printing make SiC coatings more useful and efficient.

- Using SiC coatings helps the planet by reducing waste and saving resources.

Understanding SiC Coating Technology

Cos'è il carburo di silicio (sic)?

Silicon carbide, or SiC, is a compound made from silicon and carbon atoms. It is one of the hardest materials known, ranking just below diamond on the Mohs scale of hardness. This material has been used for over a century in applications like abrasives and cutting tools. However, its unique properties have made it a key player in modern industries.

You’ll find that SiC stands out for its exceptional thermal conductivity, high melting point, and resistance to wear and corrosion. These qualities make it ideal for environments where extreme heat, pressure, or chemical exposure occurs. Whether in electronics, aerospace, or energy, silicon carbide plays a vital role in enhancing performance and durability.

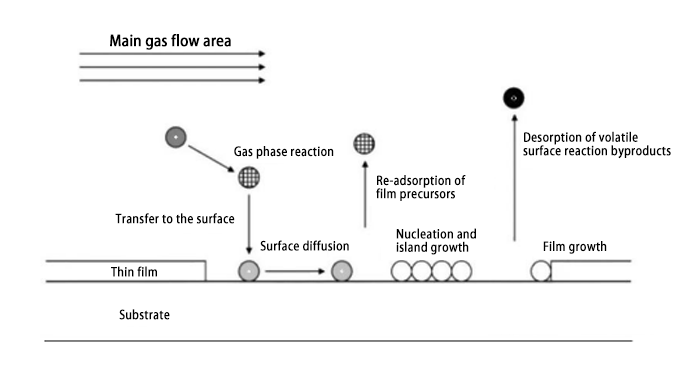

How SiC Coatings Are Manufactured

The process of creating SiC coatings involves advanced techniques to ensure precision and quality. One common method is chemical vapor deposition (CVD). In this process, silicon and carbon gases react at high temperatures to form a thin, uniform layer of silicon carbide on a substrate.

Another technique is physical vapor deposition (PVD), where SiC material is vaporized and then condensed onto a surface. Both methods allow you to achieve coatings with excellent adhesion and uniformity. Manufacturers often tailor the process to meet specific requirements, such as thickness or surface texture.

These coatings are applied to a variety of materials, including metals, ceramics, and even glass. By using these methods, you can create SiC coatings that enhance the performance and lifespan of components in demanding applications.

Key Characteristics of SiC Coatings

SiC coatings offer a range of impressive characteristics that set them apart. First, they provide superior hardness, which protects surfaces from scratches and wear. This makes them ideal for tools and equipment that face constant friction.

Second, these coatings excel in thermal stability. They can withstand temperatures exceeding 1,000°C without degrading. This property ensures reliable performance in high-temperature environments, such as furnaces or jet engines.

Third, SiC coatings resist chemical reactions, even when exposed to acids or alkalis. This chemical inertness makes them perfect for industries like chemical processing or medical devices.

Finally, SiC coatings are lightweight yet durable. This combination reduces the overall weight of components while maintaining their strength. You’ll notice this benefit in applications like aerospace, where every ounce matters.

By understanding these characteristics, you can see why SiC coating technology is becoming a cornerstone in many industries.

vantaggi del rivestimento sic

Durabilità superiore e resistenza all'usura

Lo noterai SiC coatings excel in durability. These coatings create a robust barrier that protects surfaces from wear caused by friction or repeated use. For example, tools and machinery coated with silicon carbide last significantly longer than uncoated ones. This durability reduces the need for frequent replacements, saving you time and money.

The wear resistance of SiC coatings also makes them ideal for high-stress environments. Whether you’re working with cutting tools, industrial equipment, or automotive components, these coatings ensure consistent performance. Their ability to withstand mechanical stress means fewer breakdowns and improved reliability in your operations.

High Thermal Stability and Heat Management

SiC coatings are unmatched when it comes to handling extreme temperatures. They maintain their structural integrity even at temperatures exceeding 1,000°C. This makes them indispensable in industries like aerospace, where components face intense heat during operation.

You can also rely on SiC coatings for efficient heat management. Their excellent thermal conductivity helps dissipate heat quickly, preventing overheating in sensitive equipment. For instance, in electronics, these coatings protect components by managing heat generated during high-performance tasks. This ensures that devices operate smoothly and last longer.

By using SiC coatings, you can enhance the thermal performance of your systems while reducing the risk of heat-related failures.

Chemical Inertness and Corrosion Protection

SiC coatings offer exceptional resistance to chemical reactions. They remain stable even when exposed to harsh acids, alkalis, or other corrosive substances. This chemical inertness makes them a reliable choice for industries like chemical processing, where equipment often comes into contact with aggressive chemicals.

You’ll find that SiC coatings also provide excellent corrosion protection. They form a protective layer that shields surfaces from oxidation and chemical damage. For example, in marine environments, these coatings prevent metal components from rusting due to saltwater exposure.

By applying SiC coatings, you can extend the lifespan of your equipment and reduce maintenance costs. Their ability to resist chemical and environmental damage ensures long-term reliability in demanding conditions.

Enhanced Surface Hardness and Longevity

SiC coatings significantly enhance the hardness of surfaces, making them resistant to scratches, dents, and other forms of physical damage. You’ll notice this benefit in applications where tools or components face constant mechanical stress. For instance, cutting tools coated with silicon carbide maintain their sharpness longer, ensuring precise performance over extended periods.

The increased surface hardness also contributes to the longevity of coated materials. By reducing wear and tear, SiC coatings extend the lifespan of equipment and components. This means fewer replacements and repairs, which translates to lower operational downtime. Whether you’re working in manufacturing, aerospace, or automotive industries, this durability ensures consistent performance and reliability.

Another advantage lies in the uniformity of the coating. SiC coatings create a smooth, even layer that minimizes surface imperfections. This not only improves the aesthetic appeal of the material but also enhances its functional properties. For example, in electronics, a smooth SiC coating can improve the efficiency of heat dissipation, protecting sensitive components from damage.

You can also rely on SiC coatings to maintain their hardness under extreme conditions. Unlike other materials that may degrade over time, silicon carbide retains its properties even when exposed to high temperatures, corrosive chemicals, or heavy loads. This makes it a versatile solution for a wide range of demanding applications.

Environmental and Cost Benefits

SiC coatings offer several environmental advantages. By extending the lifespan of materials, they reduce waste generated from frequent replacements. You’ll find this particularly beneficial in industries like manufacturing, where equipment and tools often wear out quickly. Longer-lasting components mean fewer resources are consumed in production, contributing to a more sustainable operation.

The lightweight nature of SiC coatings also plays a role in reducing energy consumption. For example, in the aerospace industry, lighter components lead to improved fuel efficiency. This not only lowers operational costs but also reduces carbon emissions, making your processes more environmentally friendly.

From a cost perspective, SiC coatings provide excellent value. While the initial investment may seem higher, the long-term savings outweigh the upfront costs. You’ll spend less on maintenance, repairs, and replacements, allowing you to allocate resources more effectively. Additionally, the enhanced performance of SiC-coated components can lead to increased productivity, further boosting your bottom line.

Another cost-saving aspect is the reduced need for protective measures. SiC coatings naturally resist wear, corrosion, and heat, eliminating the need for additional treatments or coatings. This simplifies your processes and reduces overall expenses.

By choosing SiC coating technology, you not only improve the performance and durability of your materials but also contribute to a more sustainable and cost-effective operation.

SiC Coating in Electronics

![]()

Protecting Semiconductor Components

You rely on semiconductor components for the backbone of modern electronics. These components often face challenges like heat, wear, and contamination. SiC coating provides a protective layer that shields semiconductors from these threats. Its chemical inertness prevents damage from corrosive substances, while its hardness resists physical wear.

In semiconductor manufacturing, precision is critical. Even minor contamination can disrupt performance. SiC coating ensures a clean, stable surface, reducing the risk of defects. This protection enhances the reliability of semiconductors in devices like smartphones, computers, and industrial machinery. By using this technology, you can improve the lifespan and efficiency of your electronic components.

Thermal Management in High-Performance Electronics

High-performance electronics generate significant heat during operation. Without proper heat management, this can lead to overheating and failure. SiC coating excels in thermal conductivity, allowing it to dissipate heat efficiently. This keeps your devices cool and ensures consistent performance.

For example, in power electronics, SiC-coated components handle high temperatures without degrading. This makes them ideal for applications like electric vehicles and renewable energy systems. You can trust SiC coating to maintain the structural integrity of components, even under extreme thermal stress.

By incorporating SiC coating, you enhance the thermal stability of your systems. This reduces the risk of heat-related failures and extends the operational life of your devices.

Applications in LED and High-Frequency Devices

LEDs and high-frequency devices demand materials that can handle intense operating conditions. SiC coating meets these requirements with its unique properties. Its ability to manage heat ensures that LEDs maintain brightness and efficiency over time. This is especially important in applications like automotive lighting and large-scale displays.

In high-frequency devices, SiC coating minimizes energy loss and improves performance. Its lightweight nature also reduces the overall weight of components, making it a preferred choice for advanced technologies. You’ll find this technology in devices like radar systems, 5G infrastructure, and satellite communications.

By using SiC coating, you can achieve better energy efficiency and reliability in these cutting-edge applications. Its versatility makes it a valuable asset in the rapidly evolving electronics industry.

SiC Coating in Aerospace and Defense

![]()

Thermal Protection for Aircraft and Spacecraft

You know that aerospace and defense applications demand materials that can endure extreme heat. SiC coating provides exceptional thermal protection for aircraft and spacecraft components. It withstands high temperatures without losing its structural integrity. This makes it ideal for parts exposed to intense heat, such as turbine blades, exhaust systems, and heat shields.

In spacecraft, re-entry into Earth’s atmosphere generates extreme temperatures. SiC coating acts as a protective barrier, preventing damage to critical components. Its ability to manage heat ensures the safety and functionality of spacecraft during these high-stress conditions. By using this technology, you can enhance the thermal performance of aerospace systems and reduce the risk of heat-related failures.

Durability in Extreme Environments

Aerospace and defense equipment often operate in harsh environments. You need materials that can resist wear, corrosion, and mechanical stress. SiC coating excels in these conditions. Its hardness protects surfaces from abrasion caused by dust, debris, or high-speed impacts.

In addition, SiC coating resists chemical reactions, even in corrosive environments like saltwater or acidic atmospheres. This makes it a reliable choice for military aircraft and naval systems. You’ll find that its durability reduces maintenance needs, ensuring consistent performance over time. Whether in the freezing temperatures of the stratosphere or the scorching heat of a desert, SiC coating maintains its protective properties.

Lightweight Coatings for Improved Efficiency

Weight plays a critical role in aerospace and defense applications. Every pound saved can improve fuel efficiency and reduce operational costs. SiC coating offers a lightweight solution without compromising strength or durability.

For example, you can apply SiC coating to aircraft components to reduce their weight while maintaining their structural integrity. This not only enhances fuel efficiency but also increases payload capacity. In defense systems, lighter materials improve mobility and performance, giving you a strategic advantage.

The combination of lightweight properties and superior protection makes SiC coating an invaluable asset in aerospace and defense. By adopting this technology, you can achieve better efficiency, reliability, and cost savings in your operations.

SiC Coating in Energy and Automotive Industries

Enhancing Solar Panel Efficiency

You know that solar panels must operate efficiently to maximize energy output. SiC coating plays a crucial role in improving their performance. By applying this coating to solar panel surfaces, you enhance their ability to absorb sunlight. The coating reduces reflection, allowing more light to penetrate the photovoltaic cells. This increases energy conversion rates and boosts overall efficiency.

SiC coating also protects solar panels from environmental damage. It resists wear caused by dust, rain, and UV radiation. This durability ensures that panels maintain their efficiency over time, even in harsh outdoor conditions. You’ll find this especially valuable in large-scale solar farms, where consistent performance is critical.

By using SiC coating, you can extend the lifespan of solar panels and reduce maintenance costs. This makes it a sustainable and cost-effective solution for renewable energy systems.

Applications in Power Electronics and EVs

Power electronics and electric vehicles (EVs) demand materials that can handle high temperatures and electrical loads. SiC coating excels in these applications. Its thermal conductivity helps dissipate heat generated by power modules, preventing overheating. This ensures reliable performance in devices like inverters and converters.

In EVs, SiC-coated components improve energy efficiency. For example, coated power modules reduce energy loss during operation, extending the vehicle’s range. You’ll also notice that SiC coating enhances the durability of battery systems, protecting them from wear and chemical damage.

This technology supports the growing demand for sustainable transportation. By incorporating SiC coating, you can improve the performance and reliability of EVs and power electronics, paving the way for cleaner energy solutions.

Improving Engine and Brake Component Durability

Automotive engines and brake systems face intense mechanical stress and heat. SiC coating provides a protective layer that enhances their durability. For engines, the coating reduces wear on critical components like pistons and cylinders. This minimizes friction, improving fuel efficiency and extending engine life.

In brake systems, SiC coating resists wear caused by constant friction. This ensures consistent braking performance and reduces the need for frequent replacements. You’ll find this especially beneficial in high-performance vehicles, where reliability is essential.

The lightweight nature of SiC coating also contributes to better vehicle efficiency. By reducing the weight of coated components, you improve fuel economy and reduce emissions. This makes SiC coating a valuable asset in the automotive industry, where performance and sustainability go hand in hand.

SiC Coating in Industrial and Medical Applications

Protezione di attrezzature e strumenti industriali

Le attrezzature industriali spesso affrontano l'usura per uso costante. Puoi usare il rivestimento SIC per Proteggi questi strumenti e macchine dal danno. La sua eccezionale durezza crea una barriera dura che resiste a graffi, abrasioni e impatti. Questa protezione garantisce che l'attrezzatura dura più a lungo e si esibisca in modo affidabile.

Nella produzione, strumenti come il taglio delle lame e i pezzi di perforazione beneficiano notevolmente del rivestimento SIC. Il rivestimento riduce l'attrito, che migliora l'efficienza e la precisione. Ad esempio, gli utensili da taglio rivestiti mantengono la loro nitidezza per periodi prolungati, riducendo la necessità di sostituti frequenti. Questo ti consente di risparmiare tempo e abbassare i costi operativi.

Il rivestimento SIC protegge anche le attrezzature dall'esposizione chimica. In settori come l'elaborazione chimica, i macchinari spesso entrano in contatto con sostanze corrosive. Il rivestimento impedisce le reazioni chimiche, garantendo che i tuoi strumenti rimangano funzionali anche in ambienti difficili. Applicando il rivestimento SIC, tu Migliorare la durata e l'affidabilità delle tue attrezzature industriali.

Rivestimenti per dispositivi medici

I dispositivi medici richiedono materiali resistenti e biocompatibili. Il rivestimento SIC soddisfa questi requisiti, rendendolo una scelta eccellente per le applicazioni sanitarie. La sua inerzia chimica garantisce che non reagisca con fluidi corporei o tessuti, mantenendo la sicurezza dei dispositivi medici.

Troverai il rivestimento SIC usato in strumenti chirurgici, impianti e strumenti diagnostici. Ad esempio, gli strumenti chirurgici rivestiti con in carburo di silicio resistono all'usura e alla corrosione, garantendo prestazioni precise durante le procedure. Gli impianti, come la sostituzione delle articolazioni, beneficiano della superficie liscia del rivestimento, che riduce l'attrito e migliora il comfort del paziente.

La natura leggera del rivestimento SIC lo rende anche ideale per i dispositivi medici portatili. Riducendo il peso dei componenti, il rivestimento migliora l'usabilità e l'efficienza di questi strumenti. In ospedale o laboratori di ricerca, il rivestimento SIC garantisce che i dispositivi medici si svolgano in modo affidabile e sicuro.

Applicazioni in ambienti industriali difficili

Gli ambienti industriali duri richiedono materiali che possono resistere a condizioni estreme. Il rivestimento SIC eccelle in questi contesti, fornendo protezione contro calore, corrosione e sollecitazione meccanica. Puoi fare affidamento su di esso per salvaguardare attrezzature in settori come petrolio e gas, mining e generazione di energia.

In ambienti ad alta temperatura, come forni o reattori, il rivestimento SIC mantiene la sua integrità strutturale. Previene i danni causati da stress termico, garantendo che l'attrezzatura funzioni in modo efficiente. In ambienti corrosivi, come piante chimiche o piattaforme offshore, il rivestimento resiste alle reazioni chimiche e all'ossidazione. Questa protezione estende la durata della vita dei macchinari e riduce le esigenze di manutenzione.

Il rivestimento SIC migliora anche le prestazioni delle apparecchiature esposte a materiali abrasivi. Ad esempio, nelle operazioni minerarie, i componenti rivestiti resistono all'usura causata da un costante contatto con rocce e detriti. Questa durata garantisce prestazioni coerenti, anche nelle condizioni più esigenti. Utilizzando il rivestimento SIC, è possibile migliorare l'affidabilità e l'efficienza delle operazioni industriali.

Tendenze future nella tecnologia del rivestimento SIC

Innovazioni nelle tecniche di rivestimento

Puoi aspettarti entusiasmanti progressi nei metodi utilizzati per applicare i rivestimenti SIC. I ricercatori stanno esplorando nuove tecniche per migliorare rivestimento di precisione ed efficienza. Uno sviluppo promettente è l'uso della deposizione di vapore chimico potenziato dal plasma (PECVD). Questo metodo consente di creare rivestimenti più sottili e più uniformi riducendo al contempo il consumo di energia.

Un'altra innovazione prevede la produzione additiva, nota anche come stampa 3D. Integrando il rivestimento SIC nei componenti stampati in 3D, è possibile ottenere progetti complessi con una maggiore durata e prestazioni. Questo approccio apre possibilità per soluzioni personalizzate in settori come i dispositivi aerospaziali e medici.

Anche la nanotecnologia svolge un ruolo nell'avanzamento delle tecniche di rivestimento SIC. Gli scienziati stanno sviluppando rivestimenti su nano-scala che offrono una durezza e una resistenza chimica ancora maggiore. Questi strati ultra-sottili possono proteggere i componenti delicati senza aggiungere peso significativo.

Espandere le applicazioni nelle industrie emergenti

Il rivestimento sic sta trovando Si fa strada nelle industrie che stanno appena iniziando a sfruttare il suo potenziale. In energia rinnovabile, ad esempio, ne vedrai l'uso nei componenti della turbina eolica. Il rivestimento protegge dall'usura e dalla corrosione, garantendo prestazioni affidabili in condizioni esterne dure.

Il settore biotecnologico è un'altra area in cui il rivestimento SIC sta avendo un impatto. La sua biocompatibilità e resistenza chimica lo rendono ideale per impianti medici avanzati e strumenti diagnostici. Puoi aspettarti di vedere più applicazioni in questo campo man mano che la tecnologia si evolve.

Nel regno dell'informatica quantistica, viene esplorato il rivestimento SIC per la sua capacità di migliorare le prestazioni dei dispositivi quantistici. Le sue proprietà termiche ed elettriche lo rendono un materiale prezioso per questa tecnologia all'avanguardia.

Sostenibilità e impatto ambientale

Il rivestimento SIC contribuisce alla sostenibilità estendendo la durata della vita dei materiali e riducendo i rifiuti. Quando si utilizza questa tecnologia, si riduce al minimo la necessità di frequenti sostituti, che conserva le risorse e riduce le esigenze di produzione.

La natura leggera del rivestimento SIC supporta anche l'efficienza energetica. Ad esempio, nel trasporto, i componenti più leggeri riducono il consumo di carburante e le emissioni. Ciò si allinea con gli sforzi globali per combattere i cambiamenti climatici.

I produttori stanno anche lavorando per rendere più ecologica la produzione di SIC. Adottando processi più verdi, mirano a ridurre l'impronta ambientale di questa tecnologia. Puoi aspettarti che i progressi futuri si concentrino sulla sostenibilità senza compromettere le prestazioni.

La tecnologia di rivestimento SIC offre una durata senza eguali, stabilità termica e resistenza chimica. Questi benefici lo rendono un punto di svolta in settori come aerospaziale, elettronica ed energia. Adottando questa tecnologia, migliorare l'efficienza, ridurre i costi ed estendere la durata della durata dei componenti critici.

FAQ

A cosa serve la tecnologia di rivestimento SIC?

Usi la tecnologia di rivestimento SIC per proteggere le superfici da usura, calore e corrosione. Migliora la durata e le prestazioni dei componenti in settori come aerospaziale, elettronica, energia e dispositivi medici.

In che modo il rivestimento SIC migliora le prestazioni termiche?

Il rivestimento SIC dissipa il calore in modo efficiente a causa della sua alta conducibilità termica. Ciò impedisce il surriscaldamento e garantisce prestazioni affidabili in ambienti ad alta temperatura come motori a reazione, elettronica di alimentazione e dispositivi a LED.

Il rivestimento SIC è rispettoso dell'ambiente?

Sì, il rivestimento SIC estende la durata della vita dei materiali, riducendo il consumo di rifiuti e risorse. La sua natura leggera migliora anche l'efficienza energetica, rendendola una scelta sostenibile per industrie come i trasporti e l'energia rinnovabile.

Il rivestimento SIC può essere applicato a qualsiasi materiale?

Puoi applicare il rivestimento SIC a metalli, ceramiche e vetro. I produttori adattano il processo di rivestimento per soddisfare materiali e applicazioni specifici, garantendo un'adesione e prestazioni ottimali.

Quali industrie beneficiano maggiormente dal rivestimento SIC?

Industrie come i campi aerospaziali, automobilistici, elettronici, energetici e medici beneficiano di più. Il rivestimento SIC migliora la durata, la resistenza al calore e la protezione chimica, rendendolo ideale per applicazioni esigenti.

In che modo il rivestimento SIC riduce i costi?

Il rivestimento SIC riduce al minimo l'usura, la corrosione e i danni da calore, riducendo i costi di manutenzione e sostituzione. La sua durata garantisce componenti più durature, risparmiando denaro nel tempo.

Il rivestimento SIC è sicuro per applicazioni mediche?

Sì, il rivestimento SIC è biocompatibile e chimicamente inerte. Garantisce sicurezza e affidabilità in dispositivi medici come impianti, strumenti chirurgici e attrezzature diagnostiche.

Quali sono le tendenze future nella tecnologia del rivestimento SIC?

Vedrai progressi nelle tecniche di rivestimento come la deposizione potenziata dal plasma e la stampa 3D. Le industrie emergenti come il calcolo quantistico e la biotecnologia stanno anche esplorando il rivestimento SIC per applicazioni innovative.

Contatto: Kelly Feng Mob/WhatsApp: 86-17386007648 Email: vendite003@china-vet.com