The Tantalum Carbide Corrosion Resistant Coated Ring by Semicera is designed for superior performance in semiconductor manufacturing. This ring offers excellent corrosion resistance, wear resistance, and high-temperature stability up to 2300°C, making it a reliable choice for epitaxy equipment. Trust Semicera for precision and durability in your high-tech applications.

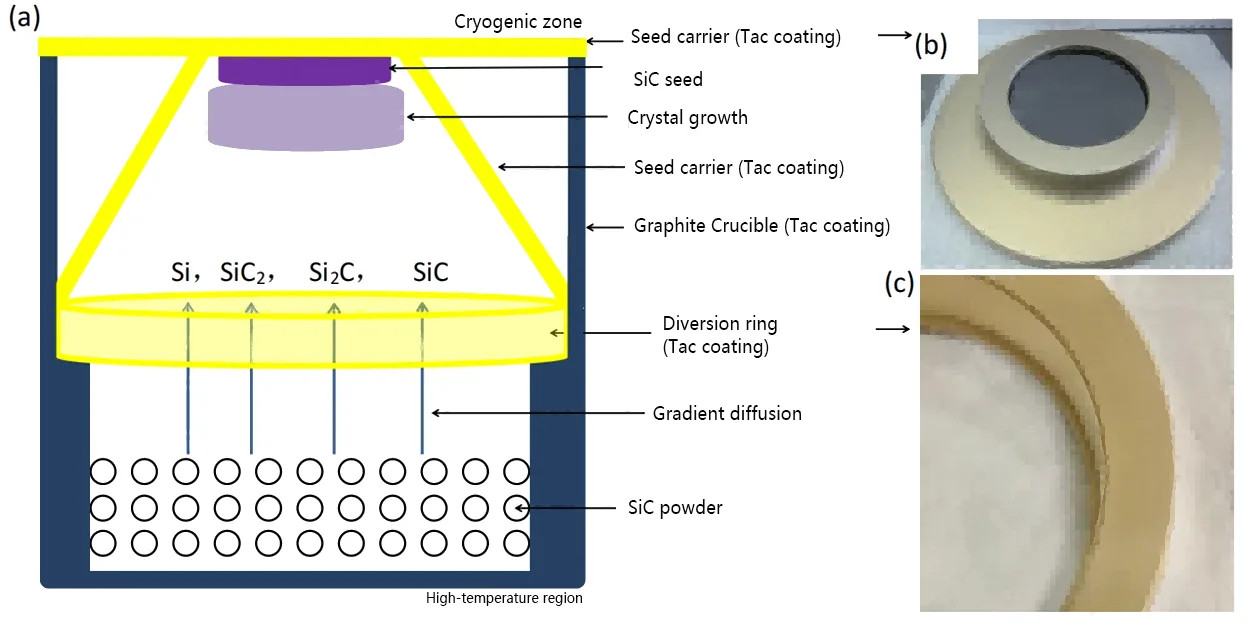

Semicera offre rivestimenti specializzati in carburo di tantalum (TAC) per vari componenti e vettori. Semicera leading coating process enables tantalum carbide (TaC) coatings to achieve high purity, high temperature stability and high chemical tolerance, improving product quality of SIC/GAN crystals and EPI layers (Graphite coated TaC susceptor), and extending the life of key reactor components. The use of tantalum carbide TaC coating is to solve the edge problem and improve the quality of crystal growth, and Semicera has breakthrough solved the tantalum carbide coating technology (CVD), reaching the international advanced level.

Tantalum carbide corrosion-resistant coating rings are widely used in various application scenarios where corrosive media exist, such as chemical, oil and gas industries, electronic equipment, medical devices, etc. They provide reliable corrosion protection, reduce corrosion and damage to parts, extend the service life of equipment, and ensure product stability and reliability.

The characteristics of tantalum carbide corrosion-resistant coating rings are as follows:

1. Corrosion resistance: Tantalum carbide coatings can resist erosion by a variety of corrosive media, including chemicals such as acids, alkalis, and salts, providing excellent corrosion resistance.

2. High temperature stability: Tantalum carbide coatings can maintain structural stability and good corrosion resistance in high temperature environments, and are suitable for applications in high temperature corrosive environments.

3. Low friction coefficient: Tantalum carbide coatings have a lower friction coefficient, reducing friction loss and energy consumption between the coating and other materials.

4. High hardness: Tantalum carbide coatings have high hardness and can resist scratches and damage to the surface of the material by corrosive media.

Moreover, Semicera’s TaC-coated products exhibit a longer service life and greater high-temperature resistance compared to SiC coatings. Laboratory measurements have demonstrated that our TaC coatings can consistently perform at temperatures up to 2300 degrees Celsius for extended periods. Below are some examples of our samples: