La grafite affronta molte sfide come usura, calore elevato ed esposizione chimica. Puoi risolvere questi problemi con a Soluzione di rivestimento in carburo di silicio. Questo strato avanzato forma uno scudo protettivo che migliora la durata e la stabilità termica. Previene anche il degrado chimico, che estende la durata della grafite. Rivestimenti in carburo di silicio Lasciare funzionare la grafite in ambienti difficili, riducendo la manutenzione e migliorando l'affidabilità. Quando applichi un Rivestimento sic sulla grafite, crei un materiale più forte e più duraturo che eccelle nelle applicazioni impegnative.

Asporto chiave

- Rivestimenti in carburo di silicio Fai durare più a lungo la grafite interrompendo danni e usura. Ciò riduce i costi di riparazione.

- Questi rivestimenti aiutano le parti di grafite a rimanere forti sotto pressione e condizioni difficili senza rompere.

- I rivestimenti in carburo di silicio mantengono la grafite stabile in calore, quindi funziona bene in luoghi caldi.

- I rivestimenti impediscono ai prodotti chimici dannosi di danneggiare la grafite, mantenendolo forte e sicuro.

- L'uso di rivestimenti in carburo di silicio significa meno problemi e migliori prestazioni in lavori difficili.

Durabilità migliorata con rivestimenti in carburo di silicio

Protezione contro l'usura

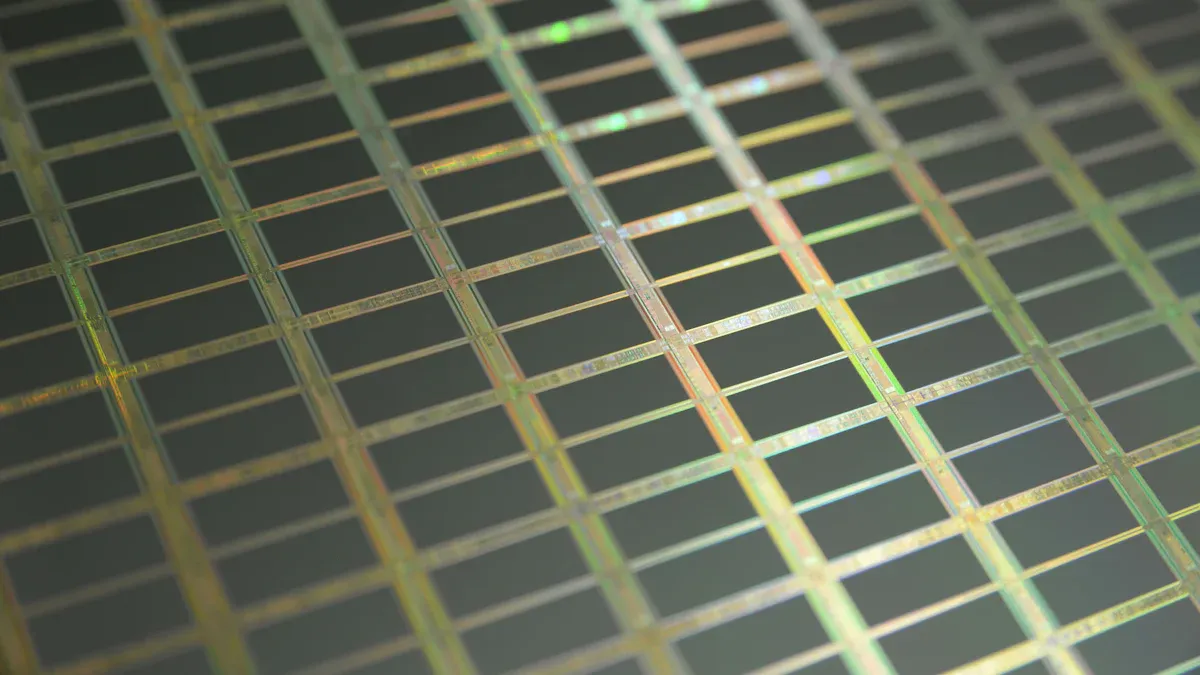

La grafite spesso lotta con l'usura in ambienti in cui l'attrito e l'abrasione sono costanti. Rivestimenti in carburo di silicio Agisci come uno strato protettivo, proteggendo la superficie dai danni causati da ripetuti contatti o movimenti. Questo rivestimento riduce la perdita di materiale e conserva l'integrità strutturale della grafite. Puoi fare affidamento su questo miglioramento per ridurre al minimo i guasti legati all'usura, in particolare nelle applicazioni che coinvolgono macchinari ad alta velocità o particelle abrasive.

Mancia: L'applicazione precoce dei rivestimenti in carburo di silicio può prevenire costose riparazioni e tempi di inattività causati da un'usura eccessiva.

Durata prolungata in condizioni di grande stress

I componenti di grafite operano spesso sotto stress estremo, sia meccanico che ambientale. I rivestimenti in carburo di silicio rinforzano la grafite, consentendole di sopportare carichi pesanti e pressione intensa senza crack o deformanti. Questa maggiore resilienza garantisce che la grafite mantenga la sua funzionalità nel tempo, anche in condizioni impegnative. Usando questi rivestimenti, si estende la durata della durata delle parti di grafite, riducendo la necessità di frequenti sostituti.

- Benefici della durata della vita prolungata:

- Costi operativi ridotti.

- Migliore affidabilità nei sistemi critici.

- Coerenza delle prestazioni migliorate.

Miglioramenti della resistenza meccanica

I rivestimenti in carburo di silicio migliorano significativamente il resistenza meccanica della grafite. Il rivestimento si lega strettamente alla superficie, creando un materiale composito robusto che resiste all'impatto e alla deformazione. Noterai che la grafite trattata con questo rivestimento può gestire livelli di stress più elevati senza compromettere la sua forma o prestazioni. Questo miglioramento lo rende ideale per le applicazioni che richiedono durata, come componenti aerospaziali o strumenti industriali.

Nota: La grafite più forte significa meno guasti e una migliore efficienza nelle operazioni.

Vantaggi per prestazioni termiche dei rivestimenti in carburo di silicio

Stabilità ad alta temperatura

La grafite affronta spesso sfide se esposte a calore estremo. I rivestimenti in carburo di silicio forniscono una soluzione da migliorare la sua capacità per resistere alle alte temperature senza degradare. Questi rivestimenti creano una barriera che impedisce l'ossidazione e il danno termico, garantendo che il materiale rimanga stabile anche a fuoco intenso. Puoi fare affidamento su questa stabilità per mantenere prestazioni coerenti in applicazioni come forni o scambiatori di calore.

Mancia: L'uso di rivestimenti in carburo di silicio può aiutarti a evitare costosi guasti causati da stress termico.

Integrità strutturale sotto calore

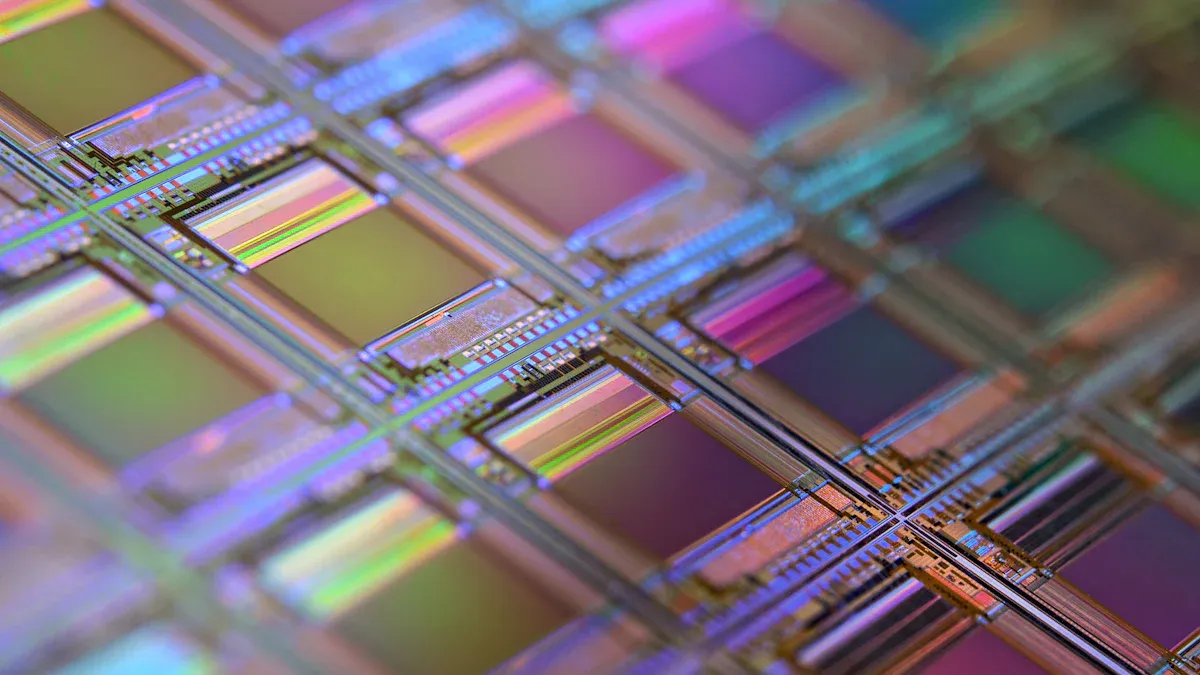

Quando la grafite si riscalda, può perdere la sua resistenza strutturale. I rivestimenti in carburo di silicio rafforzano il materiale, consentendo di conservare la sua forma e funzionalità in condizioni ad alta temperatura. Questa forza aggiuntiva garantisce che i componenti della grafite non si deformino, si spezzino o falliscano durante il funzionamento. Lo troverai particolarmente utile nelle industrie in cui la precisione e l'affidabilità sono fondamentali, come la produzione aerospaziale o semiconduttore.

- Vantaggi chiave dell'integrità strutturale:

- Migliore sicurezza in ambienti ad alto calore.

- Rischio ridotto di guasti alle attrezzature imprevisti.

- Vita di servizio più lunga per i componenti della grafite.

Applicazioni in ambienti termici estremi

I rivestimenti in carburo di silicio producono grafite Adatto per alcuni delle applicazioni termiche più esigenti. Sia che tu stia lavorando con forni industriali, ugelli a razzo o reattori ad alta temperatura, questi rivestimenti assicurano che la grafite funzioni in modo affidabile. La resistenza termica e la durata migliorate consentono di utilizzare la grafite in ambienti in cui i materiali non rivestiti fallirebbero.

Nota: Applicando rivestimenti in carburo di silicio, si espande la gamma di applicazioni in cui la grafite può essere utilizzata in modo efficace.

Resistenza alla corrosione fornita dai rivestimenti in carburo di silicio

Protezione contro il degrado chimico

La grafite affronta spesso attacchi chimici in ambienti industriali. Acidi, alcali e altre sostanze reattive possono degradare la sua superficie, riducendo la sua efficacia. Rivestimenti in carburo di silicio Agisci come barriera protettiva, proteggendo la grafite da questi prodotti chimici dannosi. Questo rivestimento impedisce agli agenti corrosivi di penetrare nel materiale, garantendo che la sua integrità strutturale rimane intatta.

Puoi fare affidamento su questa protezione per mantenere le prestazioni dei componenti di grafite negli impianti di lavorazione chimica o nei laboratori. Applicando rivestimenti in carburo di silicio, si riduce il rischio di danni chimici ed estendi l'usabilità dell'attrezzatura.

Mancia: Ispezionare regolarmente la grafite rivestita per garantire che lo strato protettivo rimanga intatto per la massima resistenza chimica.

Performance in ambienti difficili

Le impostazioni industriali spesso espongono la grafite a condizioni estreme, tra cui elevata umidità, fumi corrosivi e schizzi chimici. Questi fattori possono indebolire la grafite non rivestita nel tempo. I rivestimenti in carburo di silicio forniscono una soluzione robusta creando uno scudo resistente che resiste ai danni ambientali.

Con questo rivestimento, è possibile utilizzare con sicurezza la grafite in ambienti in cui i materiali non protetti fallirebbero. Che si tratti di piante petrolchimiche, applicazioni marine o reattori chimici, i rivestimenti in carburo di silicio garantiscono prestazioni affidabili.

- Vantaggi dell'uso di rivestimenti in carburo di silicio in ambienti difficili:

- Ridotto degrado del materiale.

- Migliorata affidabilità operativa.

- Requisiti di manutenzione inferiori.

Longevità in contesti industriali corrosivi

In settori come petrolio e gas, mining e produzione chimica, i componenti di grafite incontrano spesso sostanze corrosive ogni giorno. Senza protezione, questi materiali si degradano rapidamente, portando a frequenti sostituti e tempi di inattività. I rivestimenti in carburo di silicio migliorano significativamente la durata della grafite in tali impostazioni.

L'eccezionale resistenza del rivestimento alla corrosione garantisce che i componenti della grafite rimangono funzionali per periodi prolungati. Questa longevità riduce i costi operativi e riduce al minimo le interruzioni causate dal fallimento delle apparecchiature. Scoprirai che investire in rivestimenti in carburo di silicio paga a lungo termine migliorando l'efficienza e l'affidabilità.

Nota: I componenti di grafite più duraturi significano meno sostituti e un'operazione più sostenibile.

I rivestimenti in carburo di silicio forniscono una soluzione che cambia il gioco per migliorare le prestazioni e la durata della vita di Grafite. Questi rivestimenti migliorano la durata, la stabilità termica e la resistenza alla corrosione, rendendo la grafite più affidabile negli ambienti impegnativi. Riducendo l'usura e il danno chimico, riducono i costi di manutenzione ed estendono la durata di servizio. È possibile utilizzare questa tecnologia per ottimizzare i sistemi basati su grafite, garantendo prestazioni coerenti e efficienza a lungo termine. Le industrie che adottano questi rivestimenti beneficiano di un minor numero di guasti e una maggiore affidabilità operativa.

FAQ

Di cosa sono fatti i rivestimenti in carburo di silicio?

I rivestimenti in carburo di silicio sono costituiti da un materiale ceramico formato da silicio e carbonio. Questa combinazione crea uno strato duro e resistente che protegge la grafite da usura, calore e danni chimici. Lo troverai ampiamente utilizzato nelle industrie che richiedono materiali ad alte prestazioni.

In che modo i rivestimenti in carburo di silicio migliorano la durata della vita di Grafite?

Questi rivestimenti proteggono la grafite da danni fisici e chimici. Migliorano la durata, la stabilità termica e la resistenza alla corrosione. Riducendo l'usura e il degrado, i rivestimenti in carburo di silicio prolungano la durata dei componenti della grafite, risparmiando tempo e denaro sui sostituti.

I rivestimenti in carburo di silicio possono gestire temperature estreme?

Sì, i rivestimenti in carburo di silicio eccellono in ambienti ad alta temperatura. Impediscono l'ossidazione e il danno termico, consentendo alla grafite di mantenere la sua forza e forma. Puoi usarli in applicazioni come forni, forni e sistemi aerospaziali senza preoccuparsi dei guasti legati al calore.

I rivestimenti in carburo di silicio sono adatti alle industrie chimiche?

Assolutamente! Questi rivestimenti proteggono la grafite da acidi, alcali e altre sostanze corrosive. Li troverai ideali per impianti di trasformazione chimica, laboratori e reattori industriali in cui la grafite non rivestita si degrarebbe rapidamente.

Come posso applicare i rivestimenti in carburo di silicio alla grafite?

Processi specializzati come la deposizione di vapore chimico (CVD) o la spruzzatura al plasma vengono utilizzati per applicare rivestimenti in carburo di silicio. Avrai bisogno di attrezzature e competenze professionali per garantire un'adesione adeguata e una copertura uniforme per prestazioni ottimali.

| Contattaci per ottenere informazioni migliori |

| Di : Semicera |

| Indirizzo: No. 1958 Jiangnan Road, Ningbo High tech Zone, Zhejiang Province, 315201, Cina |

| E-mail: sales01@semi-cera.com |

| E-mail: sales05@semi-cera.com |

| Tel. 86-0574-8650 3783 |

| Telefono: 86-13373889683 |

| Skype: xianeryeah@outlook.com |

| Oggetto: 86-13373889683 |

| Xing: https: //www.xing.com/discover/your-posts |

| Pinterest: https: //www.pinterest.com/semichera/ |

| Facebook: https: //www.facebook.com/profile.php? Id = 61575124466678 |

| YouTube: https: //www.youtube.com/@semicera |