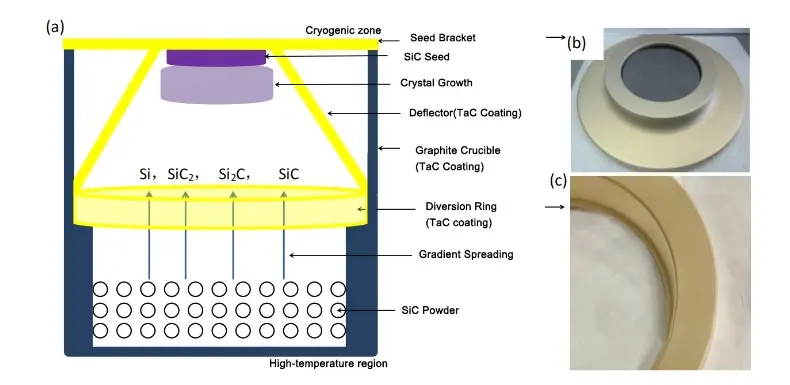

Porous tantalum carbide is mainly used for gas phase component filtration, adjusting local temperature gradient, guiding material flow direction, controlling leakage, etc. It can be used with another solid tantalum carbide (compact) or tantalum carbide coating from Semicera Technology to form local components with different flow conductance.

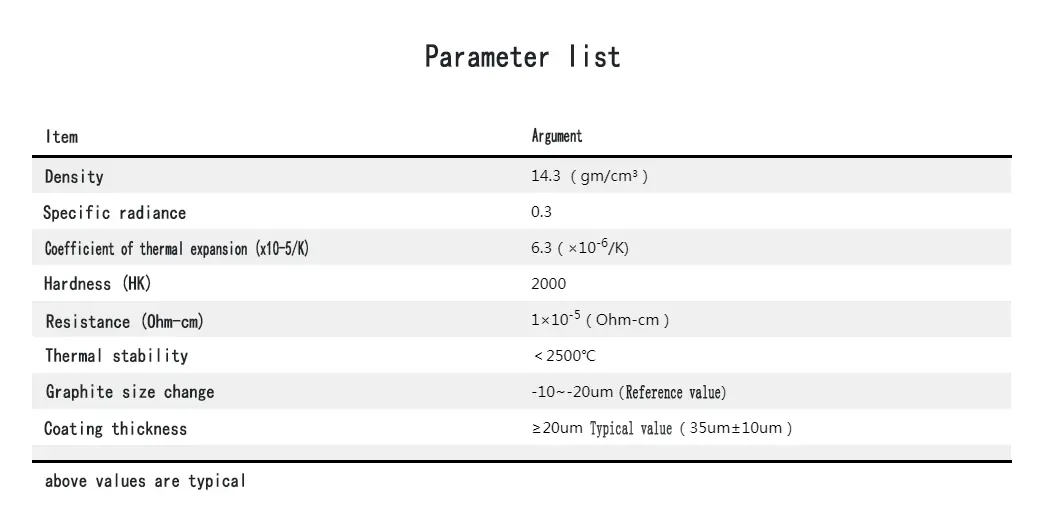

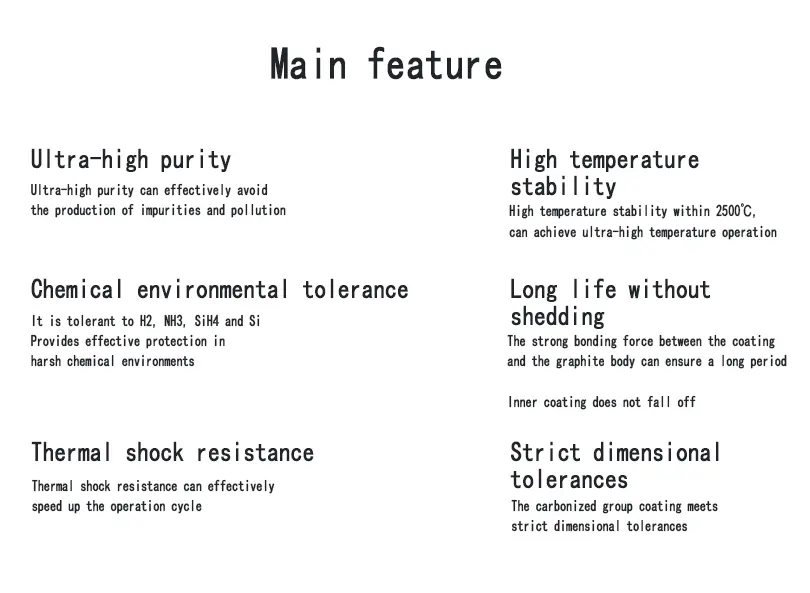

Semicera는 다양한 구성 요소 및 캐리어를위한 특수 탄탈 카바이드 (TAC) 코팅을 제공합니다. Semicera leading coating process enables tantalum carbide (TaC) coatings to achieve high purity, high temperature stability and high chemical tolerance, improving product quality of SIC/GAN crystals and EPI layers (Graphite coated TaC susceptor), and extending the life of key reactor components. The use of tantalum carbide TaC coating is to solve the edge problem and improve the quality of crystal growth, and Semicera has breakthrough solved the tantalum carbide coating technology (CVD), reaching the international advanced level.

After years of development, Semicera has conquered the technology of CVD TaC with the joint efforts of the R&D department. Defects are easy to occur in the growth process of SiC wafers, but after using TaC, the difference is significant. Below is a comparison of wafers with and without TaC, as well as Semicera’ parts for single crystal growth

In addition, the service life of Semicera’s TaC coating products is longer and more resistant to high temperature than that of SiC coating. After a long time of laboratory measurement data, our TaC can work for a long time at a maximum of 2300 degrees Celsius. The following are some of our samples: