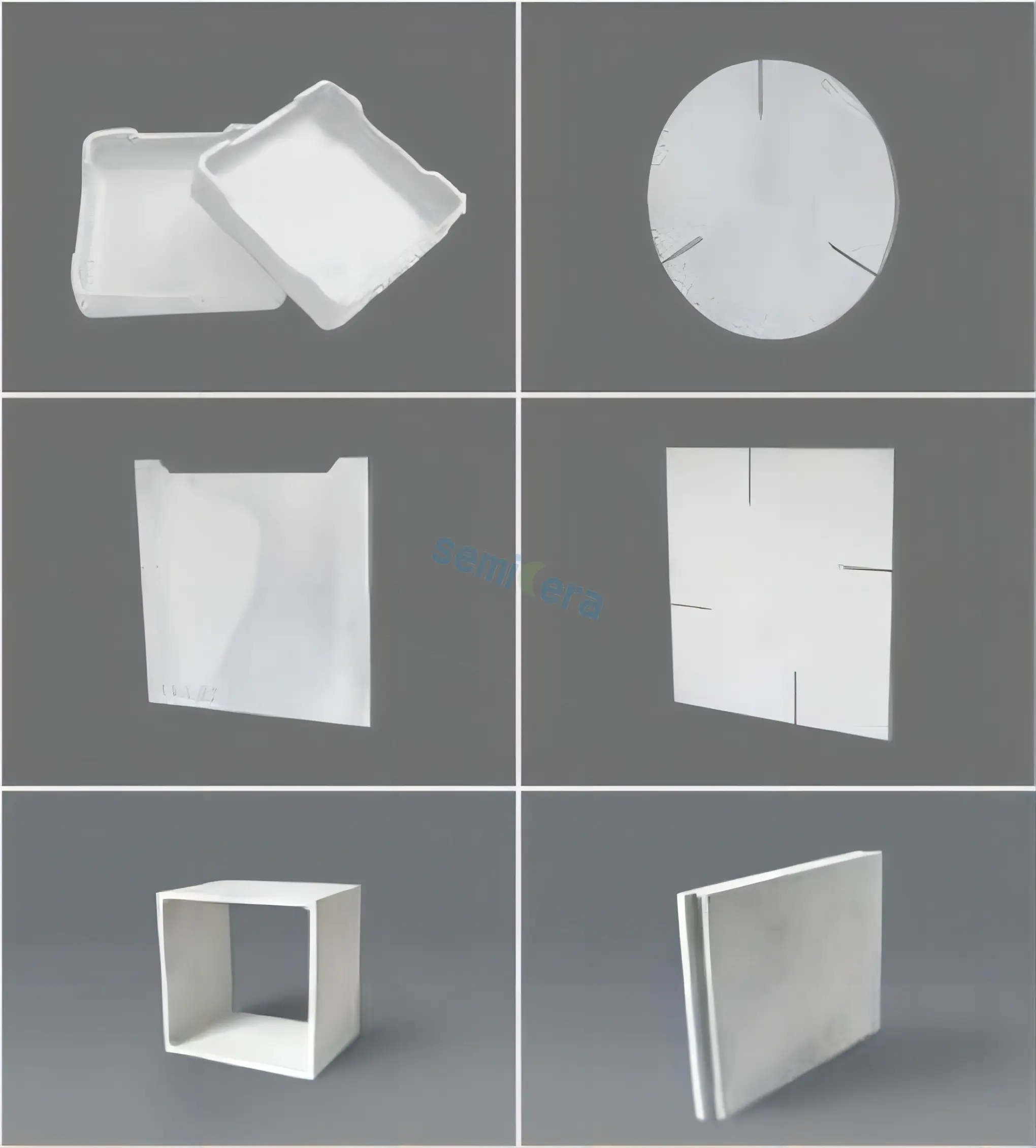

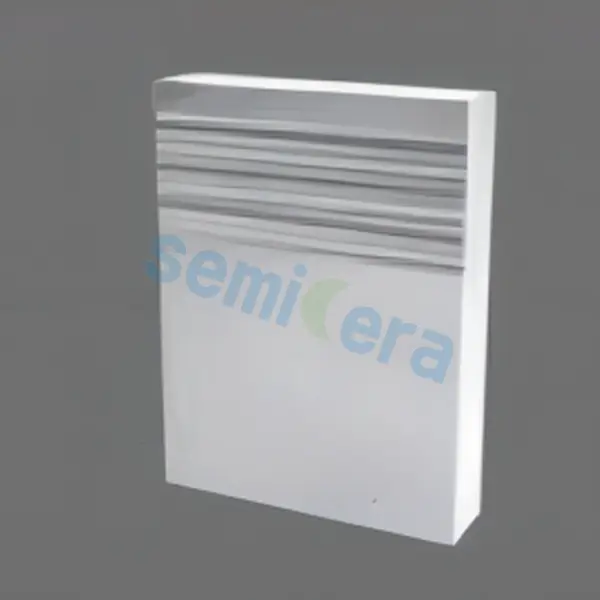

Semicera Energy Technology Co., Ltd. is a leading supplier specializing in wafer and advanced semiconductor consumables.We are dedicated to providing high-quality, reliable, and innovative products to semiconductor manufacturing,photovoltaic industryand other related fields.Our product line includes SiC/TaC coated graphite products and ceramic products, encompassing various materials such as silicon carbide, silicon nitride, and aluminum oxide and etc.As a trusted supplier, we understand the importance of consumables in the manufacturing process, and we are committed to delivering products that meet the highest quality standards to fulfill our customers’ needs.

Siliciumnitride gecombineerd met siliciumcarbide oven heeft de kenmerken van hoge temperatuursterkte, goede thermische schokweerstand, gemakkelijke vervorming, oxidatieresistentie, corrosieweerstand, goede thermische geleidbaarheid enzovoort.

|

Item |

Vuurbrick -index |

Ovenspecificatie |

Index van gevormd product |

|

Duidelijke porositeit(%) |

<16 |

<16 |

<14 |

|

Bulk density(g/cm3) |

2 2.65 |

2 2.65 |

2 2.68 |

|

Compressieve sterkte bij kamertemperatuur(MPA) |

2 160 |

2 170 |

2 180 |

|

Buigsterkte bij kamertemperatuur(1400X:) MPA |

2 40 |

2 45 |

2 45 |

|

Hoge temperatuur buigsterkte(1400r ) MPA |

2 50 |

2 50 |

2 50 |

|

Thermische expansiecoëfficiënt(110CTC) xiovc |

<4.18 |

<4.18 |

<4.18 |

|

Thermische geleidbaarheid(1100C) |

216 |

2 16 |

216 |

|

Vuurvastheid(°C ) |

1800 |

1800 |

1800 |

|

0,2 MPa Verzachting temperatuur onder belasting(X:) |

1600 |

1600 |

> 1700 |

|

Maximale bedrijfstemperatuur (°C) |

1550 |

1550 |

1550 |

De producten worden op grote schaal gebruikt in keramische slijpwiel, hoge aluminiumproducten, aluminium porseleinen bal, industriële oven, elektronisch keramisch, hoogspanning elektrisch porselein, sanitair ware, dagelijkse porselein, nitride legering en schuimceramiek en andere industrieën.

The wear resistance of Si3N4-SiC material is 3.13 times that of wear-resistant steel (Crl5Mo3), and the weight is only 1/3 of that of wear-resistant steel (Crl5Mo3).

The corrosion resistance quality reduction values of Si3N4-SiC and calcium carbide and alumina in various solutions are as follows:

|

Test solution |

Temperature(”C) |

Si3N4-SiC |

Common ceramics |

Aluminium carbide |

Aluminium oxide |

|

98 %Sulfuric acid |

100 |

1.8 |

55.0 |

> 1000 |

65,0 |

|

50 %Sodium hydroxide |

100 |

2,5 |

> 1000 |

5.0 |

75.0 |

|

53 %Hydrofluoric acid |

25 |

< 0.2 |

7.9 |

8.0 |

20,0 |

|

85 %Phosphoric acid |

100 |

< 0.2 |

8.8 |

55.0 |

> 1000 |

|

70 %Nitric acid |

100 |

< 0.2 |

0.5 |

> 1000 |

7,0 |

|

45 %Potassium hydroxide |

100 |

< 0.2 |

> 1000 |

3.0 |

60,0 |

|

25 %Hydrochloric acid |

70 |

< 0.2 |

0.9 |

85.0 |

72,0 |

|

10% Hydrofluoric acid +57% Nitric acid

|

25 |

< 0.2 |

> 1000 |

> 1000 |

16,0 |