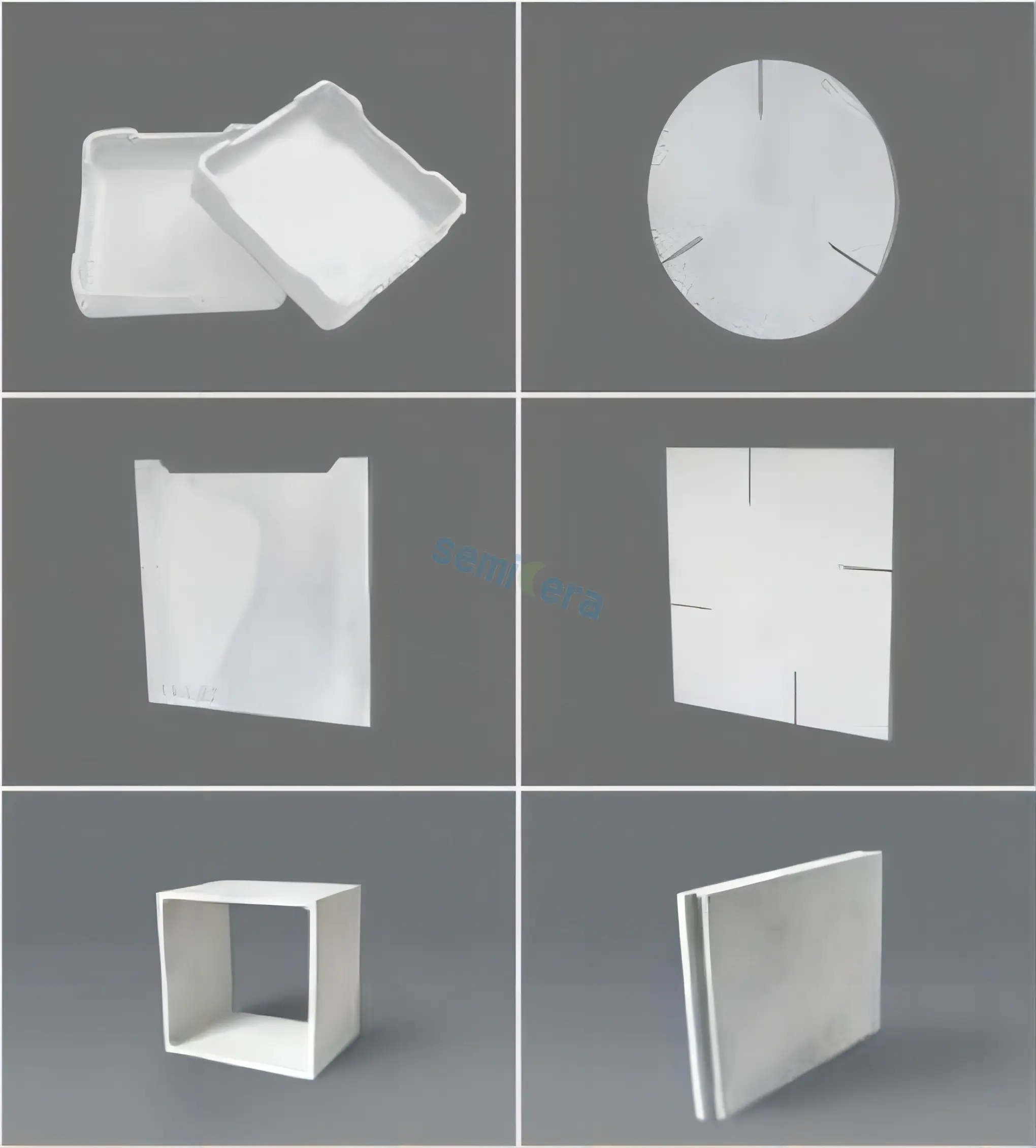

Semicera Energy Technology Co., Ltd. is a leading supplier specializing in wafer and advanced semiconductor consumables.We are dedicated to providing high-quality, reliable, and innovative products to semiconductor manufacturing,photovoltaic industryand other related fields.Our product line includes SiC/TaC coated graphite products and ceramic products, encompassing various materials such as silicon carbide, silicon nitride, and aluminum oxide and etc.As a trusted supplier, we understand the importance of consumables in the manufacturing process, and we are committed to delivering products that meet the highest quality standards to fulfill our customers’ needs.

O nitreto de silício combinado com o forno de carboneto de silício tem as características de força de alta temperatura, boa resistência ao choque térmico, fácil deformação, resistência a oxidação, resistência à corrosão, boa condutividade térmica e assim por diante.

|

Item |

Índice de Firebrick |

Especificação do forno |

Índice de produto moldado |

|

Porosidade aparente(%) |

<16 |

<16 |

<14 |

|

Densidade a granel(g/cm3) |

2 2.65 |

2 2.65 |

2 2.68 |

|

Resistência à compressão à temperatura ambiente(MPA) |

2 160 |

2 170 |

2 180 |

|

Força de flexão à temperatura ambiente(1400X:) MPA |

2 40 |

2 45 |

2 45 |

|

Força de flexão de alta temperatura(1400r ) MPA |

2 50 |

2 50 |

2 50 |

|

Coeficiente de expansão térmica(110CTC) XIOVC |

<4.18 |

<4.18 |

<4.18 |

|

Condutividade térmica(1100C) |

216 |

2 16 |

216 |

|

Refratários(°C ) |

1800 |

1800 |

1800 |

|

0,2 MPa Temperatura de amolecimento sob carga(X:) |

1600 |

1600 |

> 1700 |

|

Temperatura de operação máxima (°C) |

1550 |

1550 |

1550 |

Os produtos são amplamente utilizados na roda de moagem de cerâmica, produtos de alto alumínio, bola de porcelana de alumínio, forno industrial, cerâmica eletrônica, porcelana elétrica de alta tensão, louça sanitária, porcelana diária, liga de nitreto e cerâmica de espuma e outras indústrias.

The wear resistance of Si3N4-SiC material is 3.13 times that of wear-resistant steel (Crl5Mo3), and the weight is only 1/3 of that of wear-resistant steel (Crl5Mo3).

The corrosion resistance quality reduction values of Si3N4-SiC and calcium carbide and alumina in various solutions are as follows:

|

Test solution |

Temperature(”C) |

Si3N4-SiC |

Common ceramics |

Aluminium carbide |

Aluminium oxide |

|

98 %Sulfuric acid |

100 |

1.8 |

55.0 |

> 1000 |

65,0 |

|

50 %Sodium hydroxide |

100 |

2,5 |

> 1000 |

5.0 |

75.0 |

|

53 %Hydrofluoric acid |

25 |

< 0.2 |

7.9 |

8.0 |

20,0 |

|

85 %Phosphoric acid |

100 |

< 0.2 |

8.8 |

55.0 |

> 1000 |

|

70 %Nitric acid |

100 |

< 0.2 |

0.5 |

> 1000 |

7,0 |

|

45 %Potassium hydroxide |

100 |

< 0.2 |

> 1000 |

3.0 |

60,0 |

|

25 %Hydrochloric acid |

70 |

< 0.2 |

0.9 |

85.0 |

72,0 |

|

10% Hydrofluoric acid +57% Nitric acid

|

25 |

< 0.2 |

> 1000 |

> 1000 |

16,0 |