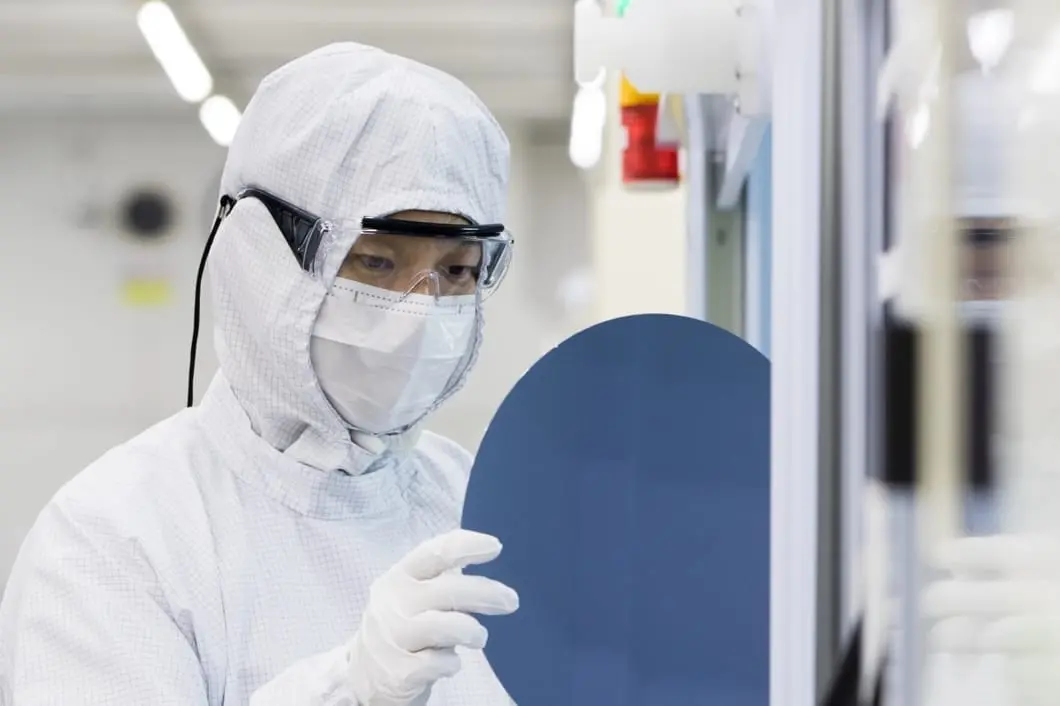

Semicera offers a wide range of 4H-8H SiC wafers. For many years, we have been a manufacturer and supplier of products to the semiconductor and photovoltaic industries. Our main products include: Silicon carbide etch plates, silicon carbide boat trailers, silicon carbide wafer boats (PV & Semiconductor), silicon carbide furnace tubes, silicon carbide cantilever paddles, silicon carbide chucks, silicon carbide beams, as well as CVD SiC coatings and TaC coatings. Covering most European and American markets. We look forward to being your long-term partner in China.

Silicon carbide (SiC) single crystal material has a large band gap width (~Si 3 times), high thermal conductivity (~Si 3.3 times or GaAs 10 times), high electron saturation migration rate (~Si 2.5 times), high breakdown electric field (~Si 10 times or GaAs 5 times) and other outstanding characteristics.

Semicera energy can provide customers with high-quality Conductive (Conductive), Semi-insulating (Semi-insulating), HPSI (High Purity semi-insulating) silicon carbide substrate; In addition, we can provide customers with homogeneous and heterogeneous silicon carbide epitaxial sheets; We can also customize the epitaxial sheet according to the specific needs of customers, and there is no minimum order quantity.

|

Unid |

Produção |

Pesquisar |

Fictício |

|

Parâmetros de cristal |

|||

|

Polytype |

4H |

||

|

Erro de orientação da superfície |

<11-20 >4±0.15° |

||

|

Parâmetros elétricos |

|||

|

Dopante |

nitrogênio do tipo n |

||

|

Resistividade |

0.015-0.025ohm·cm |

||

|

Parâmetros mecânicos |

|||

|

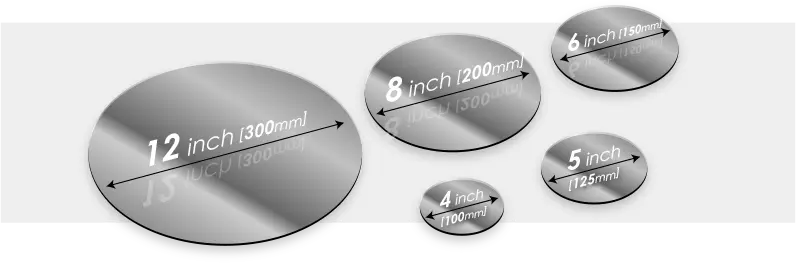

Diâmetro |

99.5 – 100mm |

||

|

Grossura |

350±25 μm |

||

|

Orientação plana primária |

[1-100]±5° |

||

|

Comprimento plano primário |

32.5±1.5mm |

||

|

Secondary flat position |

90° CW from primary flat ±5°. silicon face up |

||

|

Secondary flat length |

18±1.5mm |

||

|

TTV |

≤5 μm |

≤10 μm |

≤20 μm |

|

LTV |

≤2 μm(5mm*5mm) |

≤5 μm(5mm*5mm) |

N / D |

|

Arco |

-15μm ~ 15μm |

-35μm ~ 35μm |

-45μm ~ 45μm |

|

Urdidura |

≤20 μm |

≤45 μm |

≤50 μm |

|

A rugosidade frontal (Si-face) (AFM) |

Ra≤0.2nm (5μm*5μm) |

||

|

Estrutura |

|||

|

Densidade de micropipe |

≤1 ea/cm2 |

≤5 ea/cm2 |

≤10 ea/cm2 |

|

Impurezas de metal |

≤5E10atoms/cm2 |

N / D |

|

|

Bpd |

≤1500 ea/cm2 |

≤3000 ea/cm2 |

N / D |

|

TSD |

≤500 ea/cm2 |

≤1000 ea/cm2 |

N / D |

|

Qualidade frontal |

|||

|

Frente |

Si |

||

|

Acabamento superficial |

Si-face cmp |

||

|

Partículas |

≤60ea/wafer (size≥0.3μm) |

N / D |

|

|

Arranhões |

≤2ea/mm. Cumulative length ≤Diameter |

Cumulative length≤2*Diameter |

N / D |

|

Casca de laranja/poços/manchas/estrias/rachaduras/contaminação |

Nenhum |

N / D |

|

|

Chips/recuos/fraturas/placas de fratura/placas hexadecimais |

Nenhum |

N / D |

|

|

Áreas de poliateiro |

Nenhum |

Cumulative area≤20% |

Cumulative area≤30% |

|

Marcada a laser dianteira |

Nenhum |

||

|

Qualidade de volta |

|||

|

Final traseiro |

CMP C-FACE |

||

|

Arranhões |

≤5ea/mm,Cumulative length≤2*Diameter |

N / D |

|

|

Defeitos traseiros (chips/recuos de borda) |

Nenhum |

||

|

Rugosidade de volta |

Ra≤0.2nm (5μm*5μm) |

||

|

Marcação de laser traseiro |

1 mm (da borda superior) |

||

|

Borda |

|||

|

Borda |

Chanfro |

||

|

Embalagem |

|||

|

Embalagem |

The inner bag is filled with nitrogen and the outer bag is vacuumed. Multi-wafer cassette, epi-ready. |

||

|

*Notas : “NA” significa que nenhum item de solicitação não mencionado pode se referir ao Semi-STD. |

|||