Semicera Semiconductor Technology Co., Ltd. is a leading supplier specializing in wafer and advanced semiconductor consumables.We are dedicated to providing high-quality, reliable, and innovative products to semiconductor manufacturing,photovoltaic industryand other related fields.Our product line includes SiC/TaC coated graphite products and ceramic products, encompassing various materials such as silicon carbide, silicon nitride, and aluminum oxide and etc.As a trusted supplier, we understand the importance of consumables in the manufacturing process, and we are committed to delivering products that meet the highest quality standards to fulfill our customers’ needs.

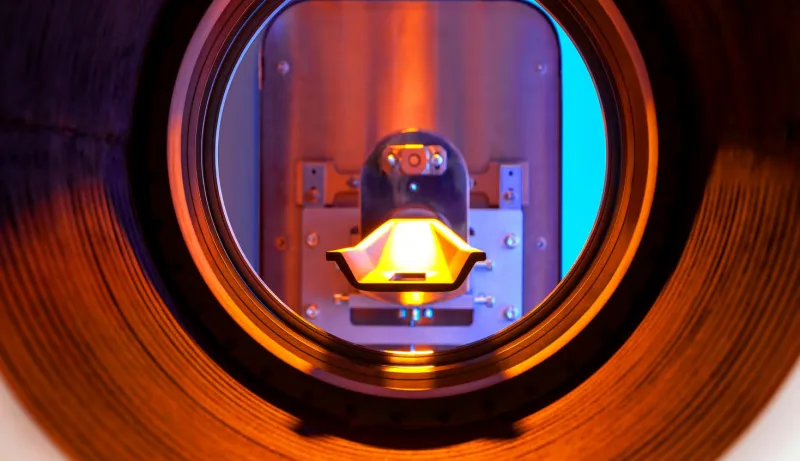

Semicera introduces high-quality semiconductor silicon carbide cantilever paddles, designed to meet the stringent demands of modern semiconductor manufacturing.

The silicon carbide paddle features an advanced design that minimizes thermal expansion and warping, making it highly reliable in extreme conditions. Its robust construction offers enhanced durability, reducing the risk of breakage or wear, which is critical in maintaining high yields and consistent production quality. The wafer boat design also integrates seamlessly with standard semiconductor processing equipment, ensuring compatibility and ease of use.

One of the standout features of the Semicera SiC paddle is its chemical resistance, which allows it to perform exceptionally well in environments exposed to corrosive gases and chemicals. Semicera’s focus on customization allows for tailored solutions.

|

Propriedades físicas de carboneto de silício recristalizado |

|

|

Propriedade |

Valor típico |

|

Working temperature (°C) |

1600°C (with oxygen), 1700°C (reducing environment) |

|

Conteúdo sic |

> 99.96% |

|

Conteúdo SI gratuito |

<0.1% |

|

Densidade a granel |

2.60-2.70 g/cm3 |

|

Porosidade aparente |

<16% |

|

Compression strength |

> 600 MPa |

|

Força de flexão fria |

80-90 MPa (20°C) |

|

Força de flexão quente |

90-100 MPa (1400°C) |

|

Thermal expansion @1500°C |

4.70 10-6/°C |

|

Thermal conductivity @1200°C |

23 W/m•K |

|

Módulo elástico |

240 GPA |

|

Resistência ao choque térmico |

Extremamente bom |