Experience unmatched durability and heat resistance with our customChemical Vapor Deposition (CVD)Tantalum Carbide (TaC)coated rings. Designed for high-temperature applications and corrosive environments, these rings offer exceptional wear resistance and performance, ensuring reliable operation and extended lifespan for your equipment.

We are proud to introduce our high-performance custom Chemical Vapor Deposition (CVD) Tantalum Carbide (TaC) coated rings, designed for extreme environments and tailored to meet the rigorous demands of industrial applications.

Each custom CVD TaC coated ring undergoes stringent quality control and testing to meet the highest standards and specific customer requirements. We are committed to delivering reliable, durable, and high-performance products to meet the most demanding application needs.

Please contact our sales team for more information, quotations, and customization options. We are dedicated to providing professional service and support to meet your needs.

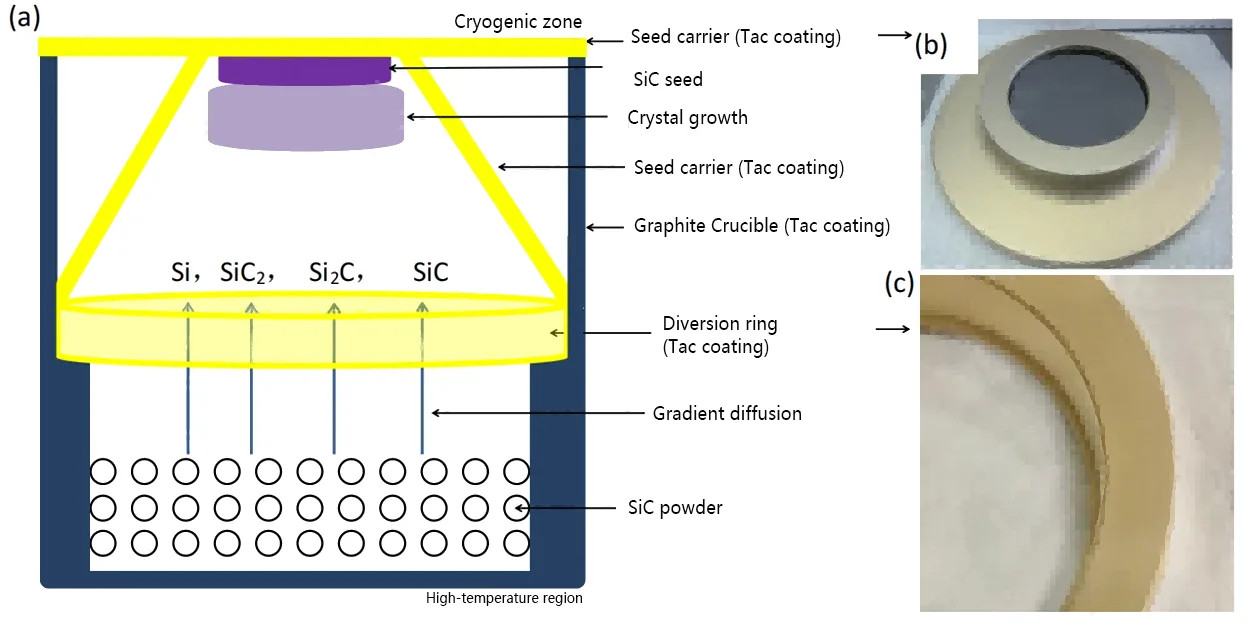

Moreover, Semicera’s TaC-coated products exhibit a longer service life and greater high-temperature resistance compared to SiC coatings. Laboratory measurements have demonstrated that our TaC coatings can consistently perform at temperatures up to 2300 degrees Celsius for extended periods. Below are some examples of our samples: