De tantalum carbide planetaire schijf van Semicera is een kritieke component in halfgeleider -epitaxie -ovens en staat bekend om zijn uitzonderlijke slijtvastheid, hoge hardheid en thermische stabiliteit. Op grote schaal gebruikt in precisie -instrumenten, ruimtevaart en halfgeleiderproductie, zorgt deze schijf voor superieure prestaties en duurzaamheid. Semicera halfgeleiders garanderen de hoogste kwaliteit en betrouwbaarheid in zeer nauwkeurige mechanische transmissiesystemen.

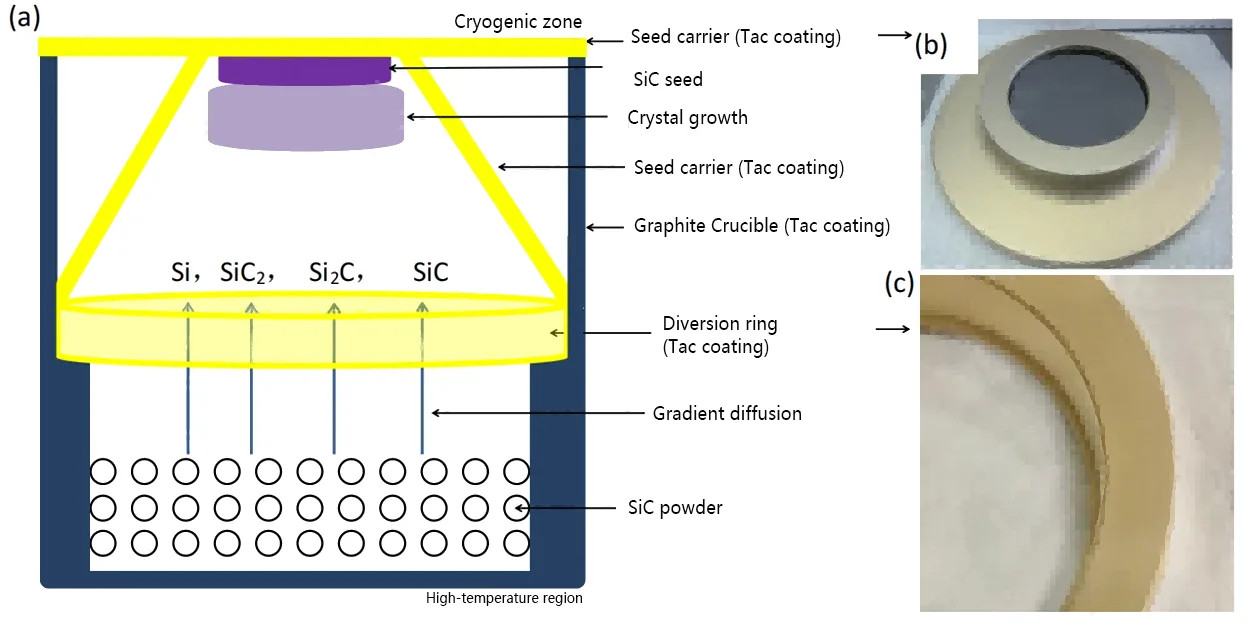

Semicera biedt gespecialiseerde tantalum carbide (TAC) coatings voor verschillende componenten en dragers. Semicera leading coating process enables tantalum carbide (TaC) coatings to achieve high purity, high temperature stability and high chemical tolerance, improving product quality of SIC/GAN crystals and EPI layers (Graphite coated TaC susceptor), and extending the life of key reactor components. The use of tantalum carbide TaC coating is to solve the edge problem and improve the quality of crystal growth, and Semicera has breakthrough solved the tantalum carbide coating technology (CVD), reaching the international advanced level.

Het werkende principe van tantalum carbide planetaire schijf is vergelijkbaar met dat van planetaire versnellingsoverdracht, waarin de planetaire schijf fungeert als een tussenliggend rijelement en realiseert stroomoverdracht en bewegingscontrole door meshing met de binnen- en buitenste versnellingen. De planetaire schijf heeft meestal meerdere tandengrooves die samengaan met de binnen- en buitenste tandwielen om een soepele transmissie en een hoge koppeluitgang te bereiken.

De kenmerken van tantalum carbide planetaire schijf zijn als volgt:

1. Draagweerstand: Tantalum carbidemateriaal heeft een extreem hoge hardheid en slijtvastheid, kan een goede duurzaamheid behouden onder hoge belasting en snelle bewegingsomstandigheden en het verlies van slijtage en wrijvingsverlies verminderen.

2. Stabiliteit met hoge temperatuur: tantalumcarbide heeft een uitstekende stabiliteit van hoge temperatuur en kan lange tijd in de omgeving met hoge temperatuur lopen zonder schade, wat geschikt is voor processen en toepassingen met hoge temperatuur.

3. Lage wrijvingscoëfficiënt: het oppervlak van tantalumcarbide heeft een lage wrijvingscoëfficiënt, die het genereren van energieverlies en warmte vermindert tijdens transmissie en de transmissie -efficiëntie verbetert.

4. Hoge precisie en stabiliteit: Tantalum carbide planetaire schijven worden vervaardigd met fijn vakmanschap, hoge precisie en stabiliteit en kunnen nauwkeurige transmissie- en positiecontrole bereiken.

Moreover, Semicera’s TaC-coated products exhibit a longer service life and greater high-temperature resistance compared to SiC coatings. Laboratory measurements have demonstrated that our TaC coatings can consistently perform at temperatures up to 2300 degrees Celsius for extended periods. Below are some examples of our samples: